Group

21

Reconditioning engine

Assembly

Install sleeve and

O-ring

in oil channel

D26

D27

Remove main bearing holders and nuts

If

any of the pin studs is

slack

torque to

15-20

Nm

(11-15

ft.lbs.).

D28

Apply sealer

Mating surfaces for lower crankcase as well as main

bearing caps should be smeared with sealer P/N

1161058-1.

D29

Install lower crankcase

Tighten nuts and bolts by hand.

Align crankcase so that rear edge is flush with cylinder

block rear. Use a straight edge. Check both sides.

IMPORTANT! Crankcase and cylinder block must be flush

otherwise distortions may result and cause noise or dama-

ge.

5098

# ©

O @

I

I I I I

1€N

©

©

J-I

o

I I I I

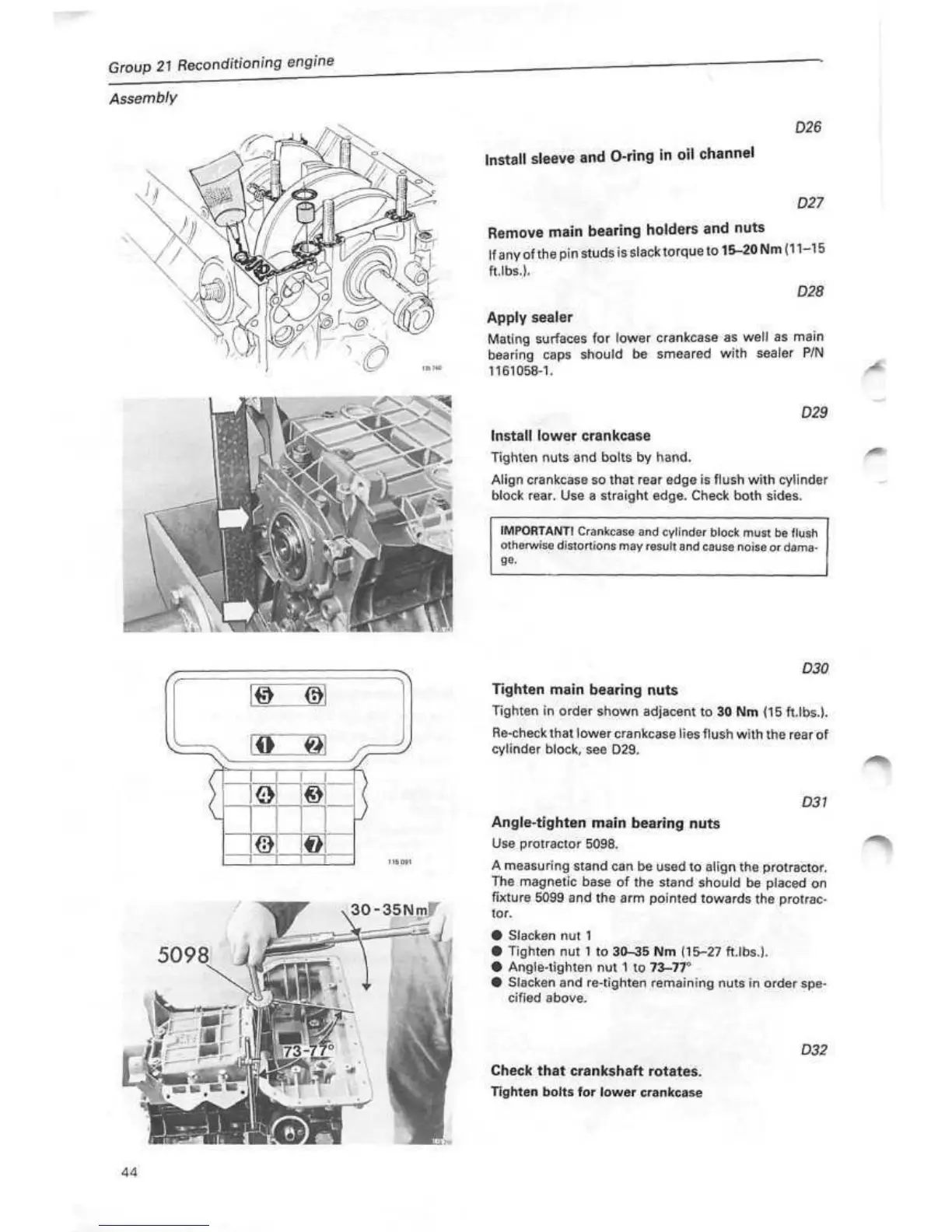

D30

Tighten main bearing nuts

Tighten in order shown adjacent to 30 Nm (15 ft.lbs.).

Re-check that lower crankcase lies flush with the rear of

cylinder block, see D29.

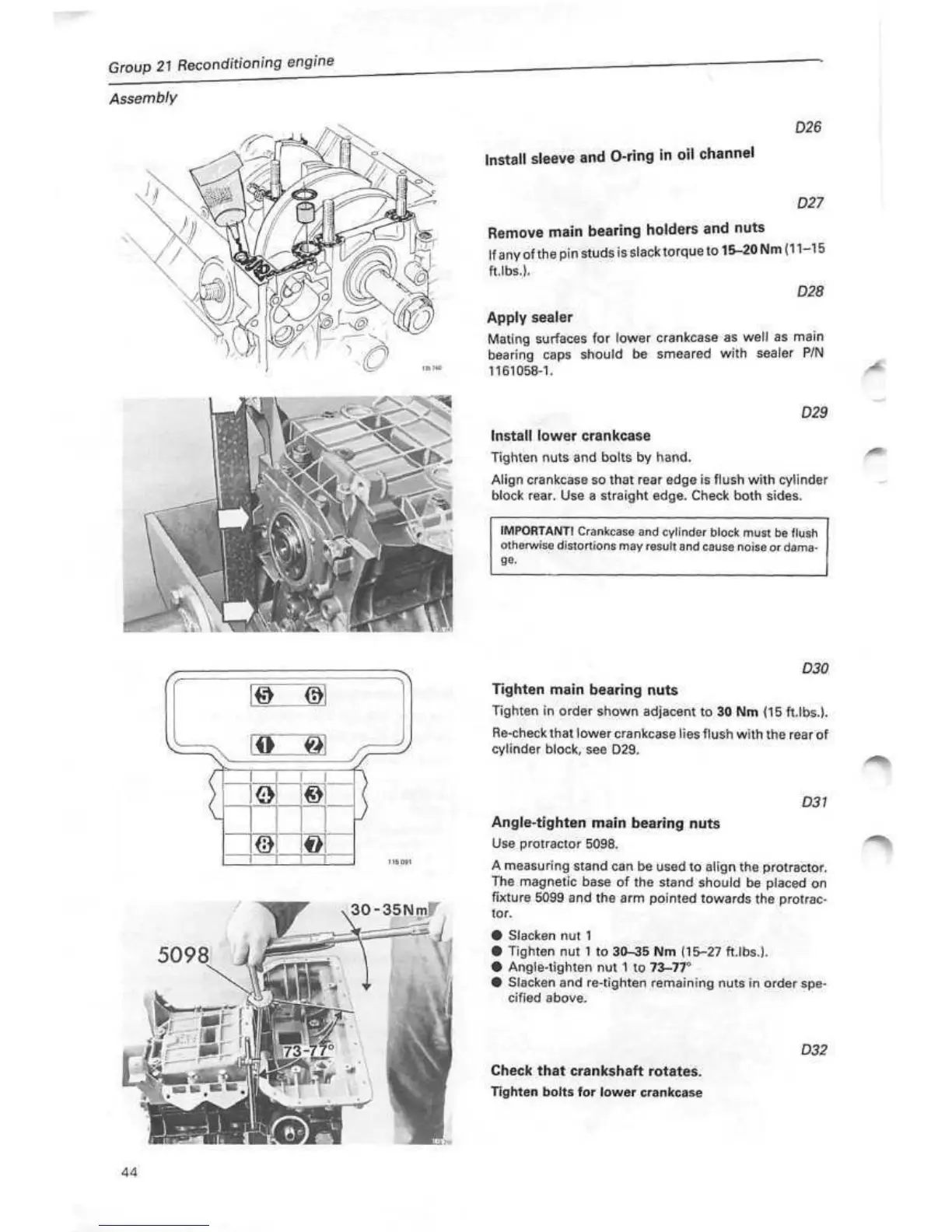

D31

Angle-tighten main bearing nuts

Use protractor 5098.

A measuring stand can be used to align the protractor.

The magnetic base of the stand should be placed on

fixture 5099 and the arm pointed towards the protrac-

tor.

• Slacken nut 1

• Tighten nut 1 to

30-35

Nm

(15-27

ft.lbs.).

• Angle-tighten nut 1 to

73-77°

•

Slacken and re-tighten remaining nuts in order spe-

cified above.

D32

Check that crankshaft rotates.

Tighten bolts for lower crankcase

44

Loading...

Loading...