General arrangement and planning

39

Selection of engine

suspension

There are two types of engine suspension; flexible

mounting with rubber mounts and rigid mounting.

Flexible mounting

Flexible engine suspension (rubber mounts) can be

used together with low gear ratios. With higher ratios,

the torsion forces and propeller axial force become

excessive for the rubber mounts.

One condition for rubber mounts to be effective

dampers is that the engine bed is sufficiently rigid.

The bed must also be parallel to engine feet to avoid

tensions being built into the engine suspension. Ten-

sions can increase the vibration level and also short-

en the life span of the mounts.

NOTE! The elasticity of the rubber mounts must nev-

er be utilised to compensate for an inclined bed.

Flexible engine mountings provide good insulation

from vibration between the engine and the bed frame,

thus contributing to a low noise level. Dimensions for

flexible mountings, see chapter Building the engine

bed.

There are two types of rubber mounts: mounts that

are adjustable in the vertical plane, and mounts with

a fixed height that must be shimmed to the correct

height.

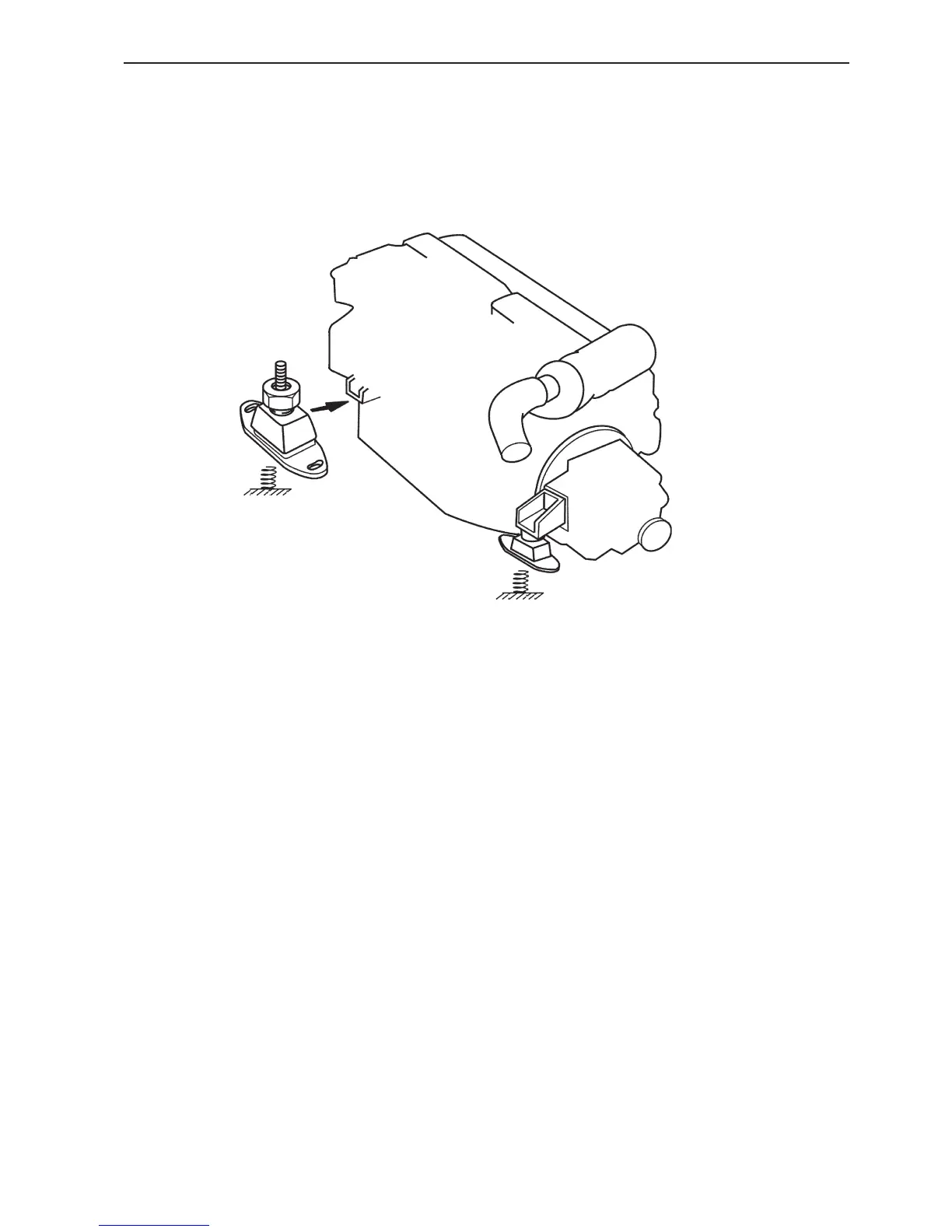

Flexible engine suspen-

sion, rubber mount

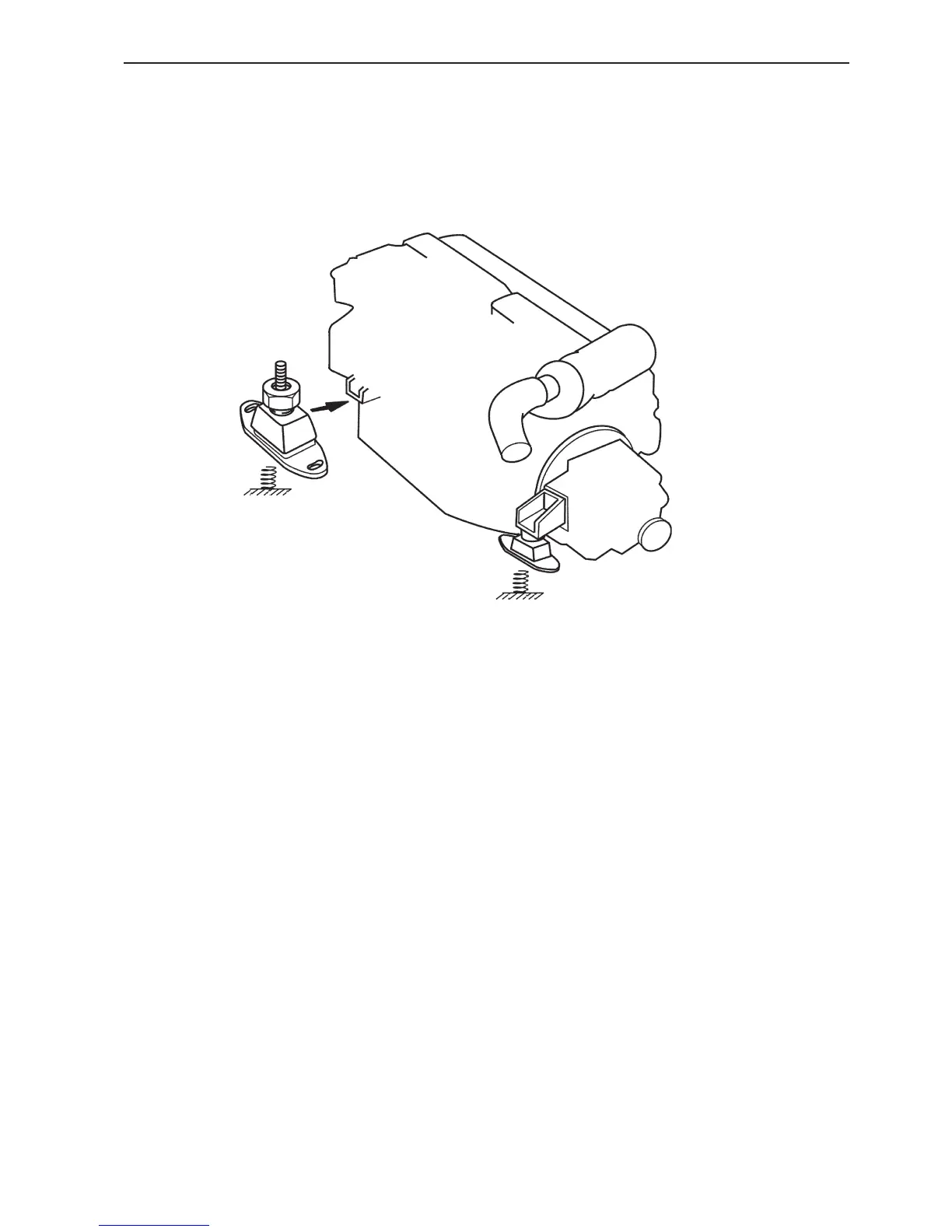

Flexible engine suspen-

sion, rubber mount

The rubber mounts are compressed during installa-

tion, therefore the engine should rest on the rubber

mounts for 12 hours before the height is adjusted.

Always follow the recommendations of Volvo Penta

when selecting the engine suspension. The use of

incorrect rubber mounts can result in abnormal vi-

brations, which in turn can cause damage to engine

components and also reduce the degree of comfort.

NOTE! When flexible engine suspension is selected,

all the connection of components to the engine must

be flexible.

The propeller shaft must have a flexible stuffing box,

or alternatively a flexible shaft coupling.

The engine’s connections for fuel lines, exhaust and

coolant must be flexible.

Loading...

Loading...