3 Troubleshooting and Testing

29

Meritor WABCO Maintenance Manual 34 (Revised 03-16)

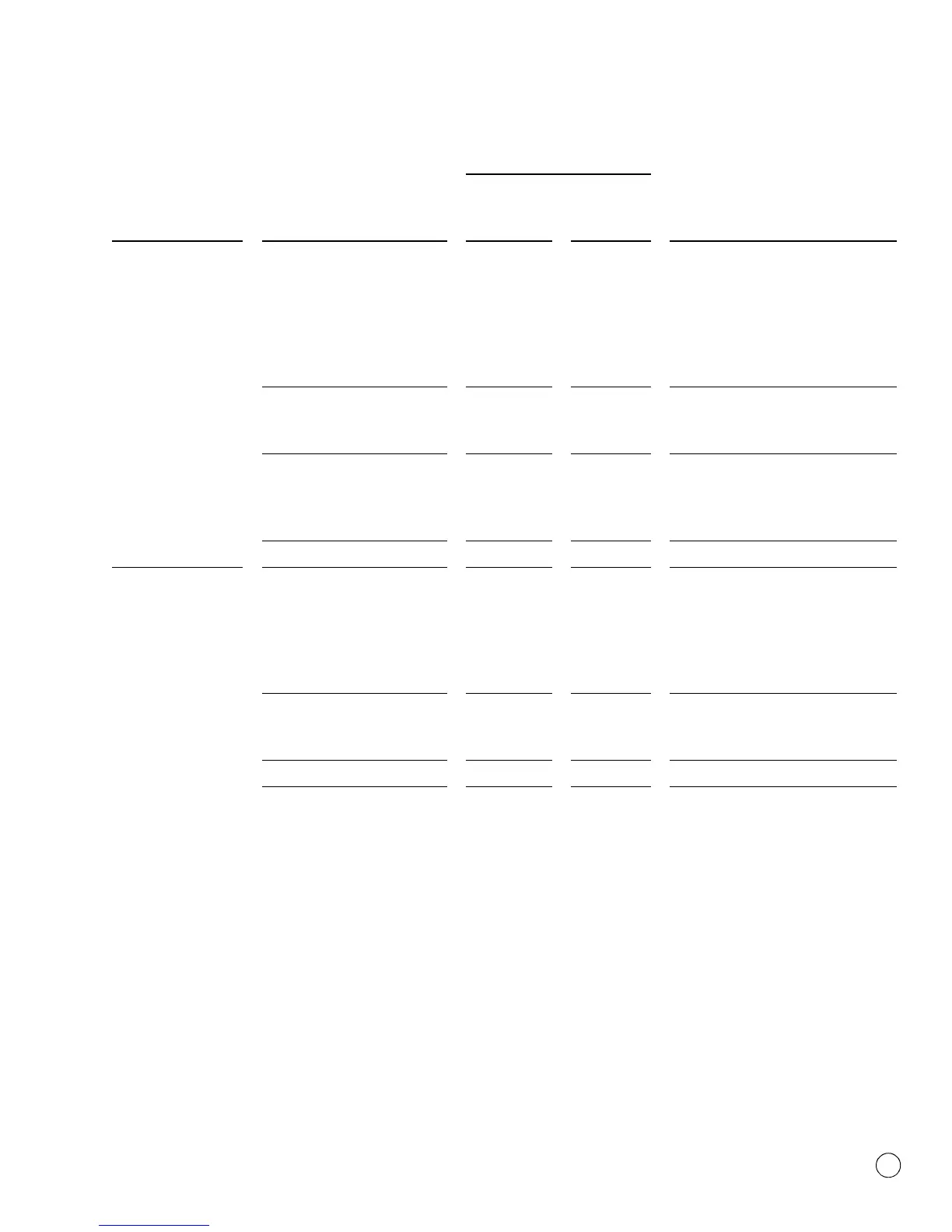

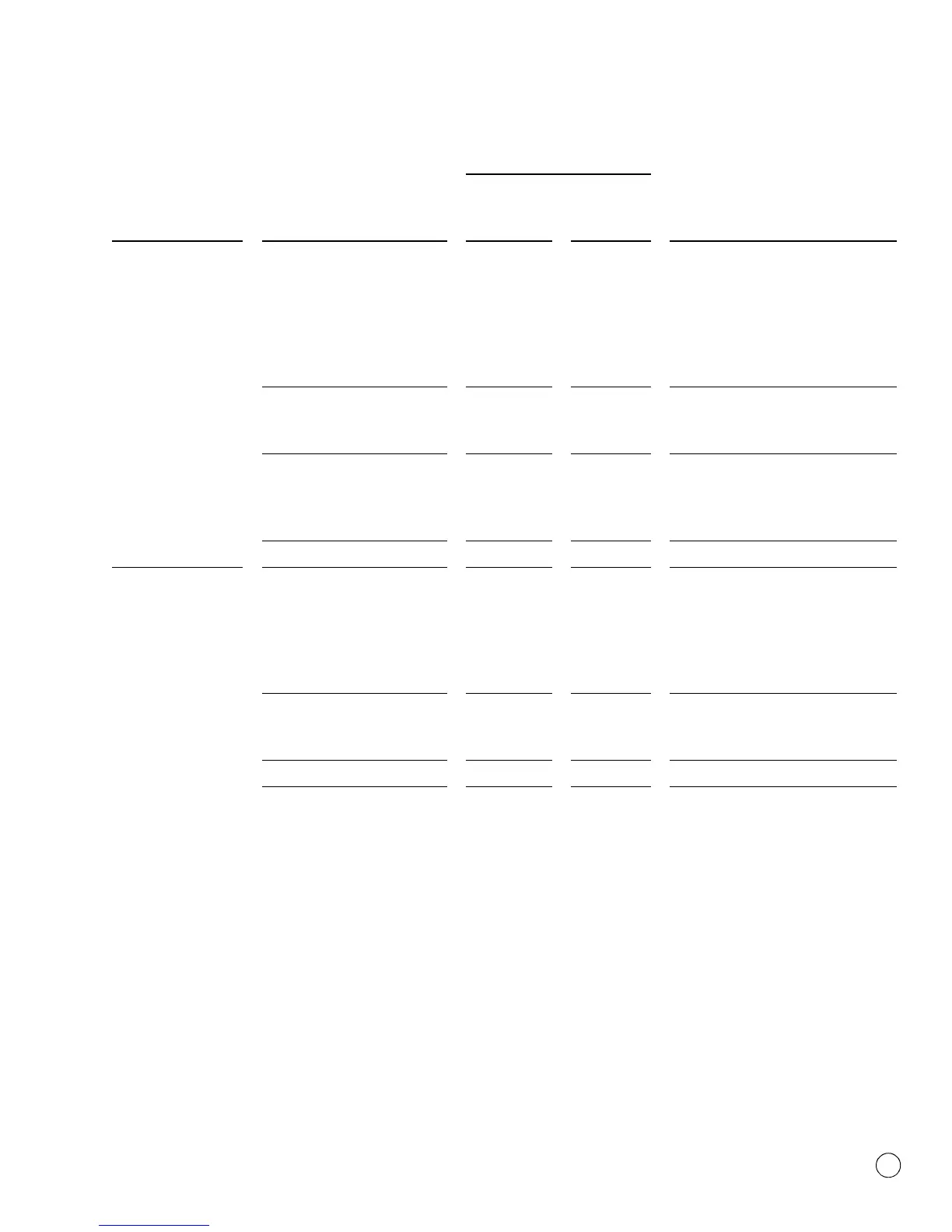

Air leak at turbo

cut-off valve vent.

Rubber seal

damaged or missing.

NOTE: As of Nov.

2009, the turbo

cut-off valve will have

an O-ring instead of a

lip seal.

Temperature of air coming into

dryer is too high — not enough

cooling takes place before dryer

inlet.

Yes Yes Move dryer farther from compressor.

Add additional compressor discharge

line before air dryer. Add cooling coil or

heat exchanger before air dryer.

NOTE: Inlet air temperature must not

exceed 175°F (80°C).

Lip seal installed upside-down

on piston. Lip must face UP

(towards dryer).

Yes Yes Install lip seal correctly.

Valve bore worn excessively. Yes Yes Inspect valve bore for wear. If a new

turbo cut-off valve does not seal in a

clean, lubricated bore, replace the air

dryer.

Piston is broken. Yes Yes Replace the turbo cut-off valve.

Air dryer frozen

(water collecting in

base of dryer is

freezing).

No electrical power to heater

connector.

Yes Yes Check for a blown fuse. Repair heater

circuit.

NOTE: There must be power to the

heater connector the entire time the

vehicle’s ignition is ON.

Low voltage to heater connector. Yes Yes Repair cause of low voltage, such as

poor electrical ground, bad connections,

corroded wire splices, etc.

Heater assembly not working. Yes Yes Replace heater assembly.

Wrong voltage air dryer used;

i.e., 12-volt air dryer used in a

24-volt system.

Yes Yes Replace with correct voltage air dryer.

Condition Possible Cause

Conditions May Occur In:

Solution

Regeneration

Style Air

Dryers

Dedicated

Purge Tank

Air Dryers

Loading...

Loading...