Crankcase Rammer Repair

116 wc_tx001548gb.fm

Assembly

6.3.14 If the needle bearing was removed, press a new bearing into the cover

until the outer race is flush with the flange surface.

NOTICE: Keep the inside of the clutch drum absolutely free of any oil

and grease.

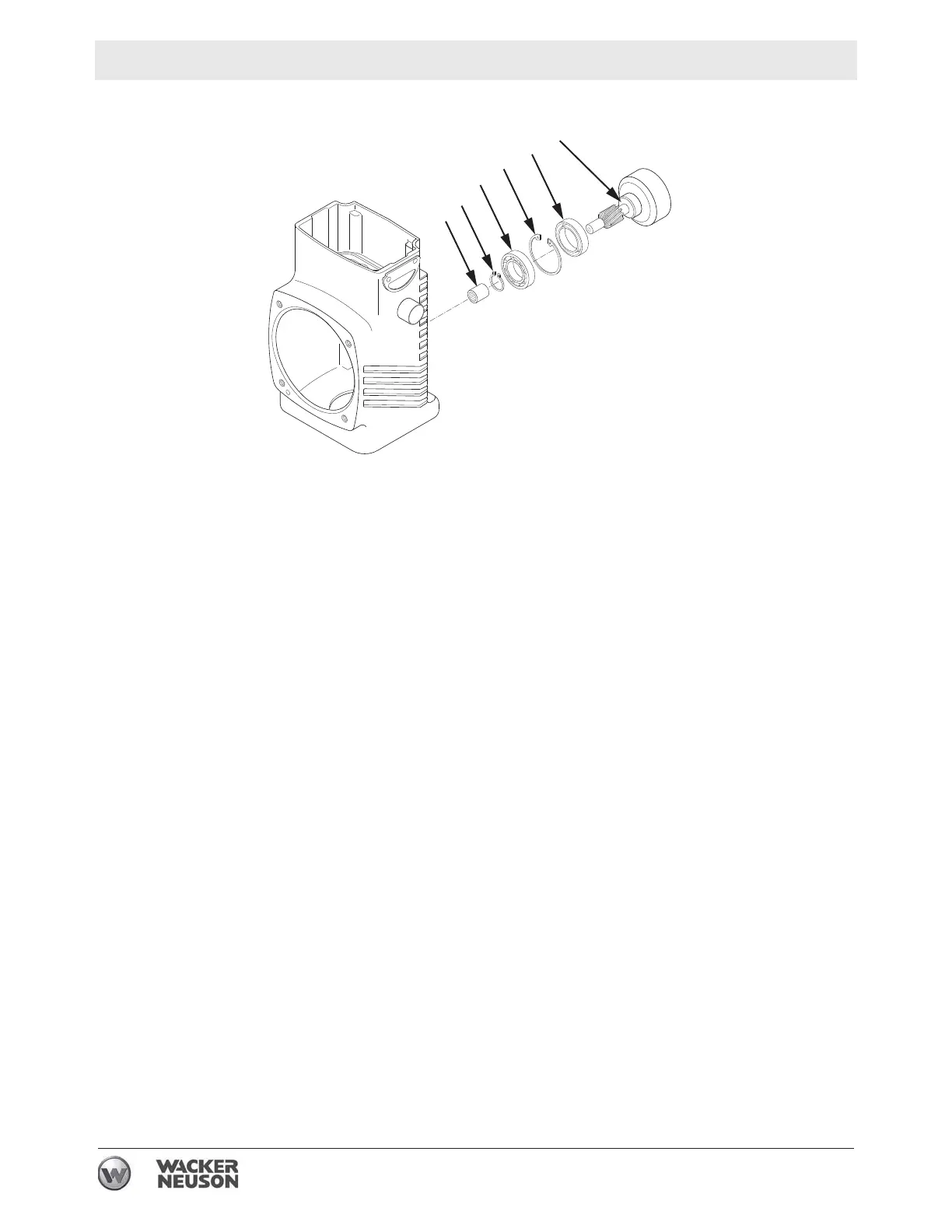

6.3.15 Press the clutch drum ball bearing into the crankcase.

6.3.16 Secure the bearing with the large retaining ring.

6.3.17 Pack the shaft seal cavity with Shell Alvania RL2 grease. Install the

shaft seal with the open side facing toward the bearing.

6.3.18 Press the clutch drum into the crankcase.

6.3.19 Secure the clutch drum with the small retaining ring.

6.3.20 Assemble the cover to the crankcase. Apply Loctite 243 and torque the

screws to 49 Nm (36 ft.lbs.).

6.3.21 Connect the crankcase to the ramming system as follows:

a. Position the upper machinery over the guide cylinder.

b. Align the connecting rod inside the ram.

c. Install the piston pin and the end plugs.

Note: Use new end plugs whenever the piston pin has been removed.

d. Fasten the guide cylinder to the crankcase. Apply Loctite 243 and

torque the screws to 43 Nm (32 ft.lbs.).

a

wc_gr001335rm

b

c

d

e

f

Loading...

Loading...