BA D18 us* 1.1 * D18w710.fm 7-41

Maintenance 7

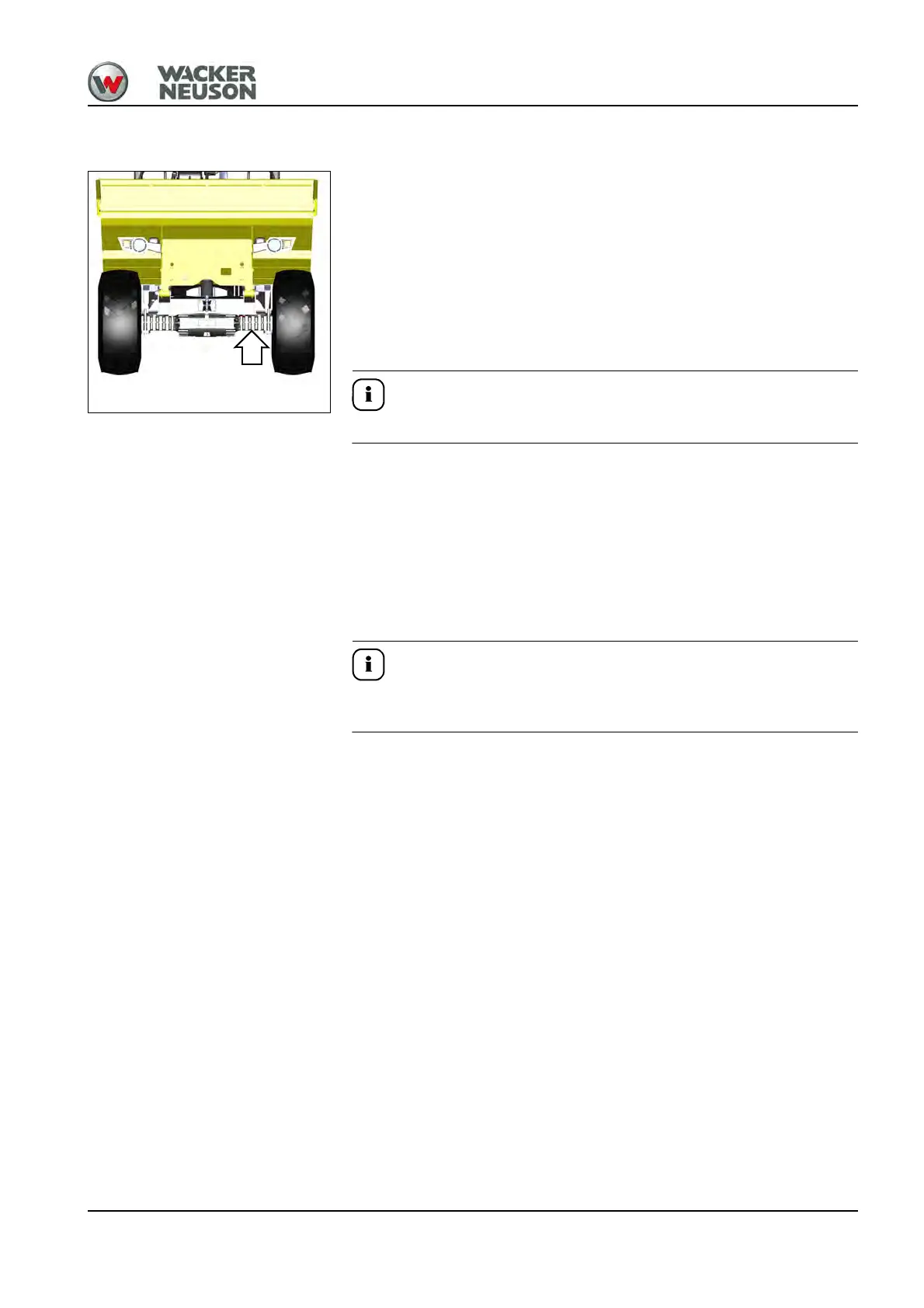

Wheel change

1. Park the machine on firm, level and horizontal ground.

2. Apply the parking brake.

3. Use wheel chocks to prevent the machine from rolling away.

4. Loosen the wheel nuts of the wheel you want to remove.

5. Place a jack with a lift capacity of 5,000 kg (11,023 lbs) under the axle

mounting ensuring stability.

6. Raise the machine on the side where you want to change a wheel.

7. Check the machine is standing firmly.

8. Secure the machine with trestles in appropriate places.

Trestles must be positioned so as to avoid machine damage.

9. Loosen and remove the wheel nuts.

10.Remove the wheel.

11.Place the new wheel onto the wheel bolts.

➥ Bear in mind the correct direction of rotation of the tires.

12.Tighten opposite wheel nuts alternately.

13.Remove the trestles.

14.Lower the raised side of the machine.

15.Tighten opposite wheel nuts alternately to 450 Nm (332 ft.lbs).

After changing a wheel, check the wheel nuts for tightness after 10

operating hours. Retighten the wheel nuts if necessary.

7.19 Maintenance of attachments

Not available.

7.20 Maintenance of options

– see chapter “7.2 Maintenance overview” on page 7-2

Loading...

Loading...