PS (3-Phase) Series Maintenance

wc_tx000132gb.fm 25

Lubricant Inspection and Changing Procedures

• Inspection interval: Every 3,000 hours or 6 months, whichever comes

first.

• Changing interval: Every 6,000 hours or 12 months, whichever comes

first.

• Designated lubricant: Turbine oil VG32 (SAE 10W/20W).

• Lubricant capacity: Specified capacity (Refer to the table, “Specified

Lubricant Capacity”.)

Inspecting Lubricant

Remove the oil plug and take out a small amount of oil. The oil can be

extracted easily by tilting the pump so that the oil plug faces downward.

If the oil appears discolored or intermixed with water, a likely cause is

a defective shaft-sealing device (i.e. mechanical seal), which requires

that the pump be disassembled and repaired.

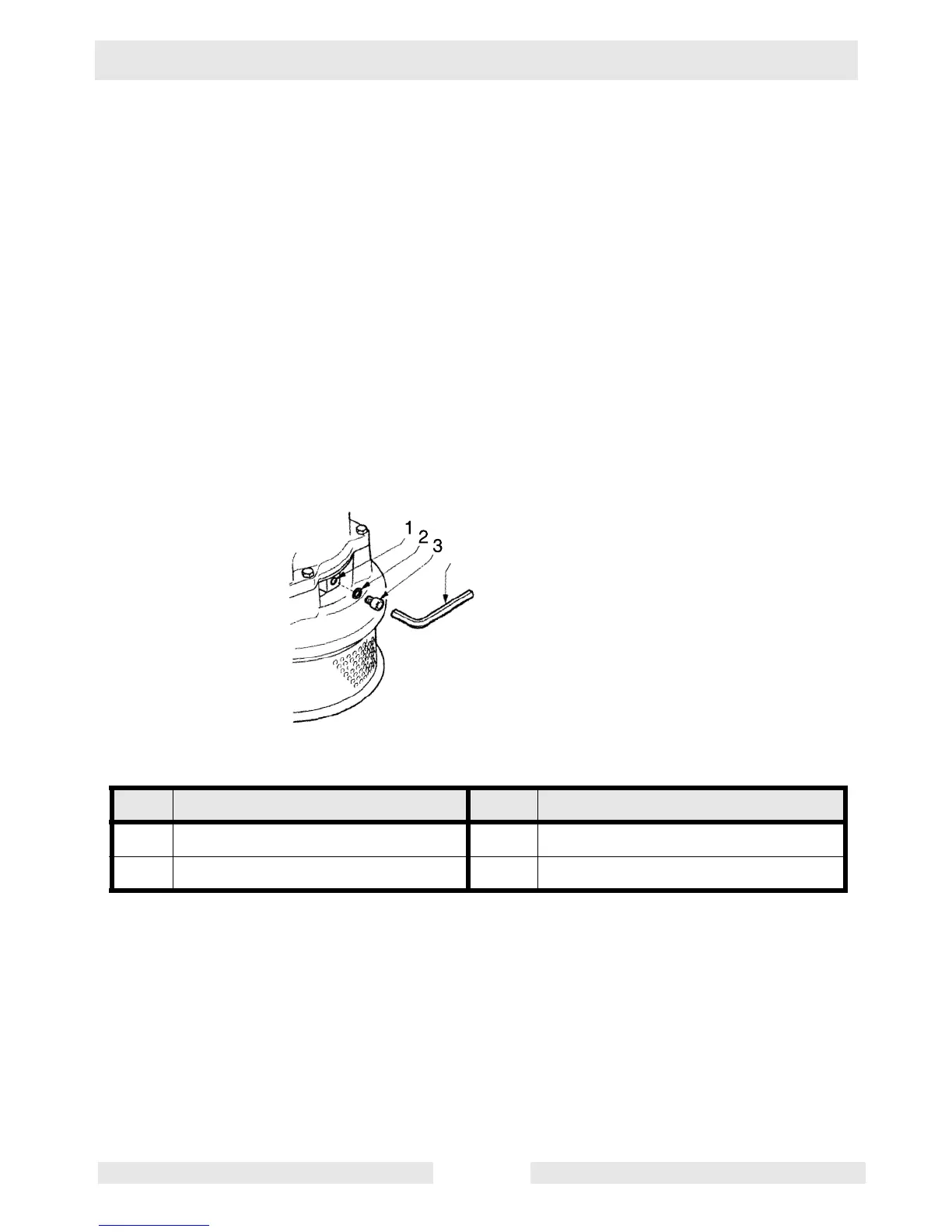

See Graphic: wc_gr000336

Changing Lubricant

Remove the oil plug and drain the oil completely. Pour a specified

volume of oil into the oil filler inlet.

Note:

The drained oil must be disposed of by waste disposal

contractors in compliance with the laws of the locale where the pump

is being used.

Ref. Description Ref. Description

1. Oil Inlet 3. Oil Plug

2. Gasket 4. Allen Wrench

wc_gr000336

Loading...

Loading...