Do you have a question about the WAGNER Model 9140 and is the answer not in the manual?

Risks and prevention for high-pressure injection injuries.

Prevention of fire, explosion, and risks from hazardous vapors.

Hazards from incompatible materials causing explosions.

Proper grounding procedures for electrical safety.

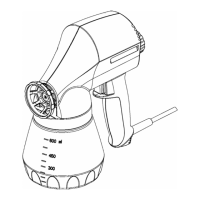

List of parts included in the shipping carton.

Explanation of sprayer controls and their operations.

Chart detailing spray gun models and compatible tip sizes.

Tools required for assembling the sprayer.

Instructions for attaching handle, pail bracket, hose, and suction/return tubes.

Procedure for locking and unlocking the spray gun trigger.

Connecting power and relieving spray hose pressure.

Steps before priming and recommendations for paint straining.

Specific instructions based on whether the unit is new or has been used.

Process for purging paint through the pump.

Process for purging paint through the spray hose.

Guidance on practicing spray patterns.

Tips for achieving an even coating with even strokes.

Further advice for effective spraying and maintenance.

Steps to clear a clogged spray tip.

Procedure for cleaning the spray gun filter.

Procedure for cleaning the suction set screen.

Steps to recover excess paint and flush the hose.

Procedure for cleaning the suction set components.

Detailed steps for cleaning the gun filter and tip assembly.

Procedures for storing the sprayer for short periods.

Steps for preparing the sprayer for extended storage.

Procedures for shutting down and starting up the sprayer.

Routine cleaning procedures for daily operation.

Information on replacing wear parts and repair kits.

Detailed steps for cleaning the sprayer's inlet valve assembly.

List of available accessories for the sprayer.

Step-by-step guide to disassembling the fluid section.

Step-by-step guide to reassembling the fluid section.

Specific service note for the Model 9210 inlet check ball.

List of parts for GX-06/07 in English.

List of parts for GX-06/07 in French.

List of parts for GX-06/07 in Spanish.

List of parts for GX-08 in English.

List of parts for GX-08 in French.

List of parts for GX-08 in Spanish.

List of parts for GX-10 in English.

List of parts for GX-10 in French.

List of parts for GX-10 in Spanish.

List of parts for cart and stand assemblies in English.

List of parts for cart and stand assemblies in French.

List of parts for cart and stand assemblies in Spanish.

| Type | Airless Paint Sprayer |

|---|---|

| Max Pressure | 3000 PSI |

| Power Source | Electric |

| Voltage | 120 V |

| Spray Tip Size | 0.015 in |

Loading...

Loading...