55

Maintenance Instructions

CHECKING/SERVICING/

REPLACING/REPAIRING

Forward Speed Control Friction Lock

The FSC friction lock is designed to hold the se-

lected forward travel speed when the steering le-

vers are moved and yet the friction is not too heavy

to make moving the FSC control difficult (too much

friction). The procedure for checking the FSC fric-

tion lock is as follows:

1. With the engine off, place the FSC in the full

FORWARD position and pull both steering le-

vers back; the FSC lever should not move. If

the FSC lever moves back when the steering

levers are pulled back, the friction needs to be

increased.

2. With the steering levers held back, move the

FSC lever back from the FORWARD position.

With a proper amount of friction adjusted, the

FSC lever should move back with a slight

amount of resistance (friction). If the FSC lever

movement is “stiff”, the friction needs to be

decreased.

If the FSC friction lock needs to be adjusted, refer to

ADJUSTMENTS for Step 7 - Forward Speed Con-

trol Friction Adjustment in this section.

REPLACING/REPAIRING

DANGER

To prevent accidental starting of the en-

gine when replacing parts or repairing the

machine, remove the key from the ignition

switch and disconnect the spark plug

wires.

IMPORTANT: ALWAYS use genuine factory re-

placement parts. Substitute parts CAN result in

product malfunction and possible injury to the op-

erator and/or others.

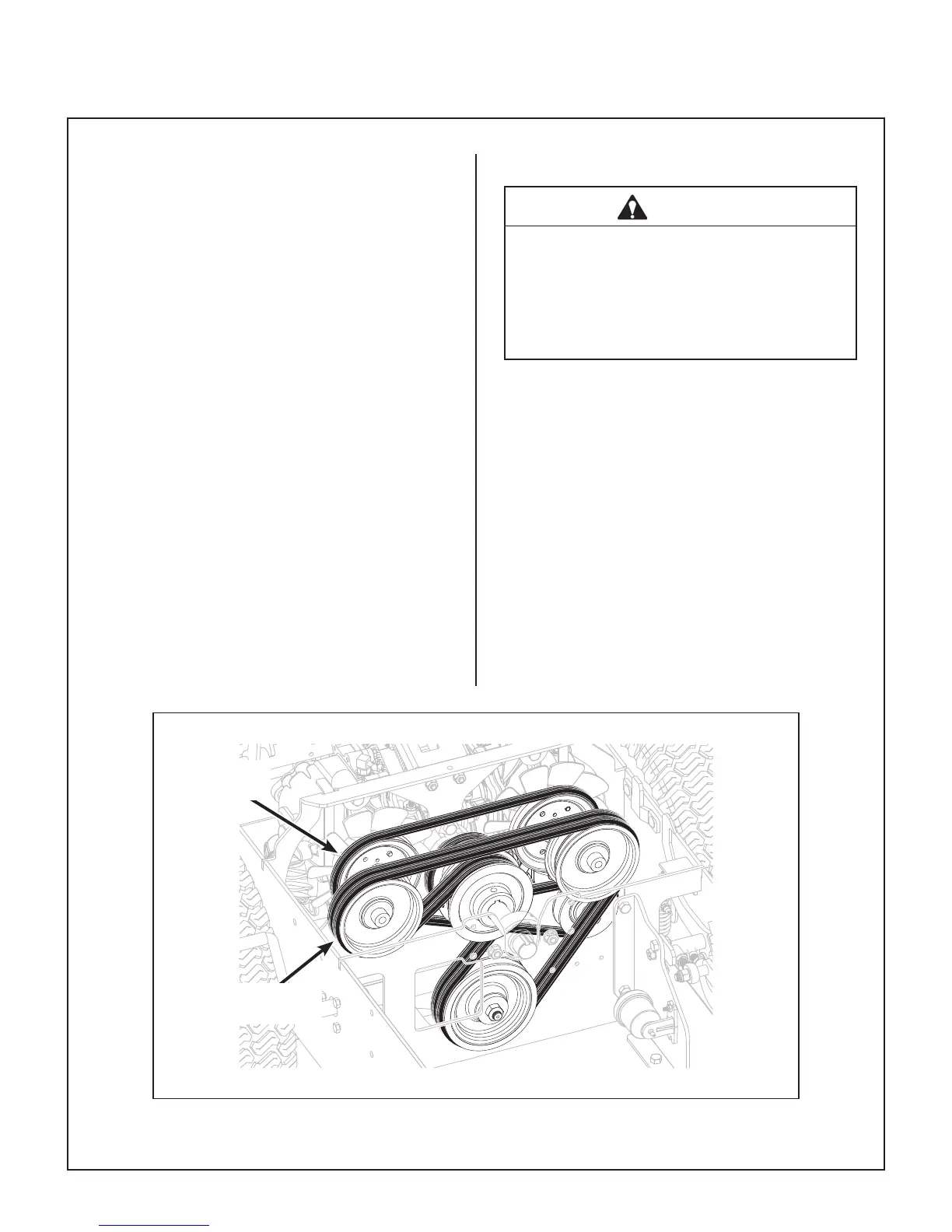

Drive Belts

There are three (3) individual belts on the ma-

chine:

• Engine/PTO Belt (Matched Set of 2)

• Ground Drive Belt

The belts may be removed and replaced using the

procedures described on the following pages.

Belt Locations

Ground

Drive Belt

Engine/PTO Belts

(Matched Set of 2)

Loading...

Loading...