45

8 TROUBLE SHOOTING

The Wallenstein 3 Point Hitch Wood Chipper is designed with blades on a rotor to cut, shear and chip wooden

material. It is a simple and reliable system that requires minimal maintenance.

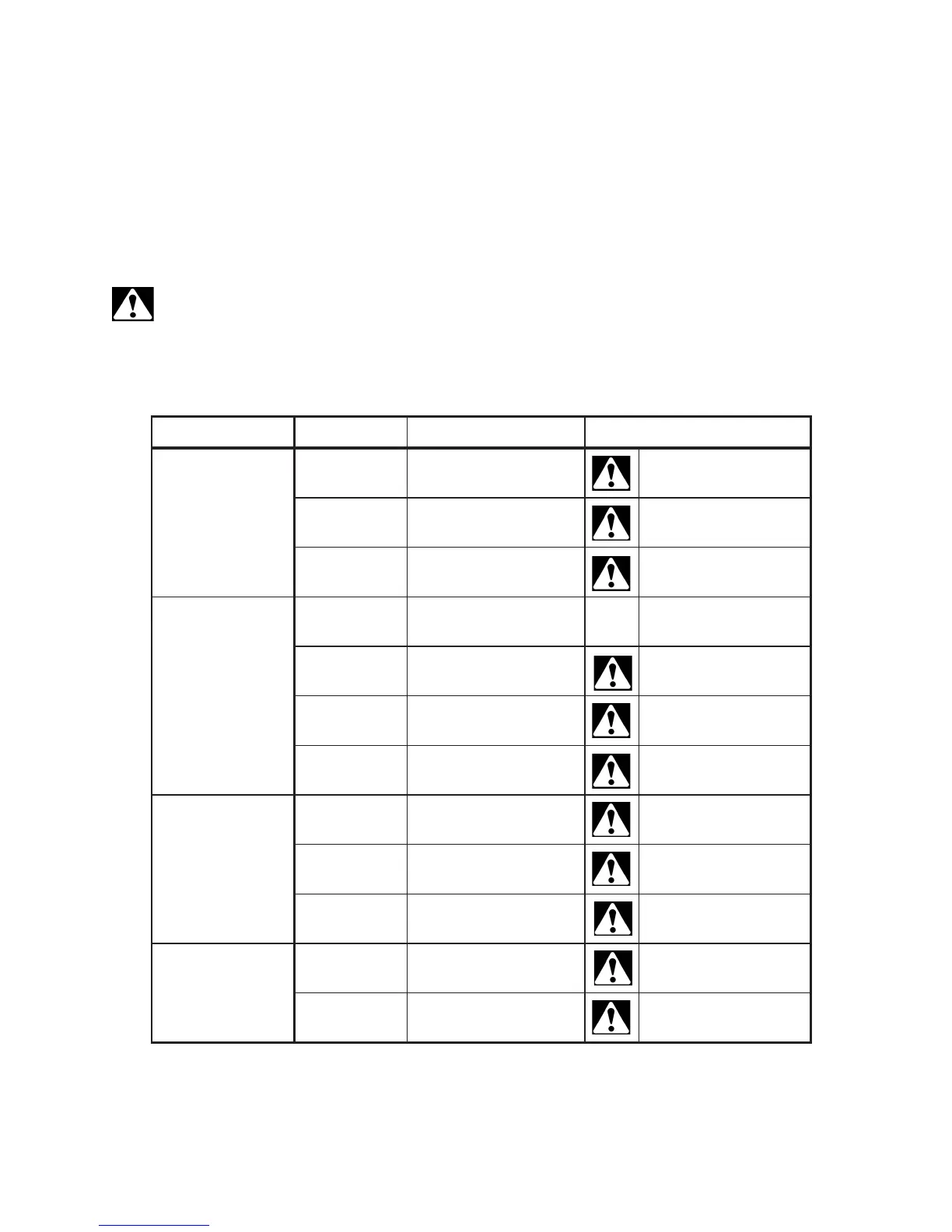

In the following section, we have listed many of the problems, causes and solutions to the problems that

you may encounter.

If you encounter a problem that is difcult to solve, even after having read through this trouble shooting

section, please call your local distributor or dealer. Before you call, please have this Operator's Manual from

your unit and serial number ready.

8�1 TROUBLE SHOOTING CHART

Always wear the appropriate safety gear when trouble shooting, performing maintenance or working

around the machine. This includes but is not limited to:

• Hard hat for protection to the head. • Face mask for protection to the face and eyes.

• Heavy gloves for hand protection. • Safety shoes with slip resistant soles and steel toes

Obstructed discharge.

Clear debris from discharge chute.

Ensure machine is off

Rotor plugged.

Inspect and clear chipper hopper

lower rotor housing and rotor.

Ensure machine is off

Broken shear pin Replace shear pin. Ensure machine is off

Low engine speed.

Throle is set to specified speed

(540 -1000)

Blades and/or knives

are dull.

Rotate, sharpen or replace blade

and/or knives.

Ensure machine is off

Rotor blade angle

wrong, improper

angle.

Re-sharpen knives to specified

angle and check that blade is

installed properly.

Ensure machi

ne is off

Obstructed discharge.

Clear debris from discharge chute .

Ensure machine is off

Broken or missing

blade .

Replace broken/missing blade. Ensure machine is off.

PTO driveline out of

phase

Align driveline Ensure machine is off.

Rotor may be bent

Check rotor to see if it wobbles.

Replace rotor

Ensure machine is off, call

technician for repair

Loose or worn belts.

Adjust or replace belts.

Ensure machine is off

Plugged rotor.

Clear rotor.

Unusual vibraon while

running.

Drive belts slipping or

smoking.

PROBLEM CAUSE SOLUTION CAUTION

Rotor does not turn

Slow feeding.

Ensure machine is off

Loading...

Loading...