49

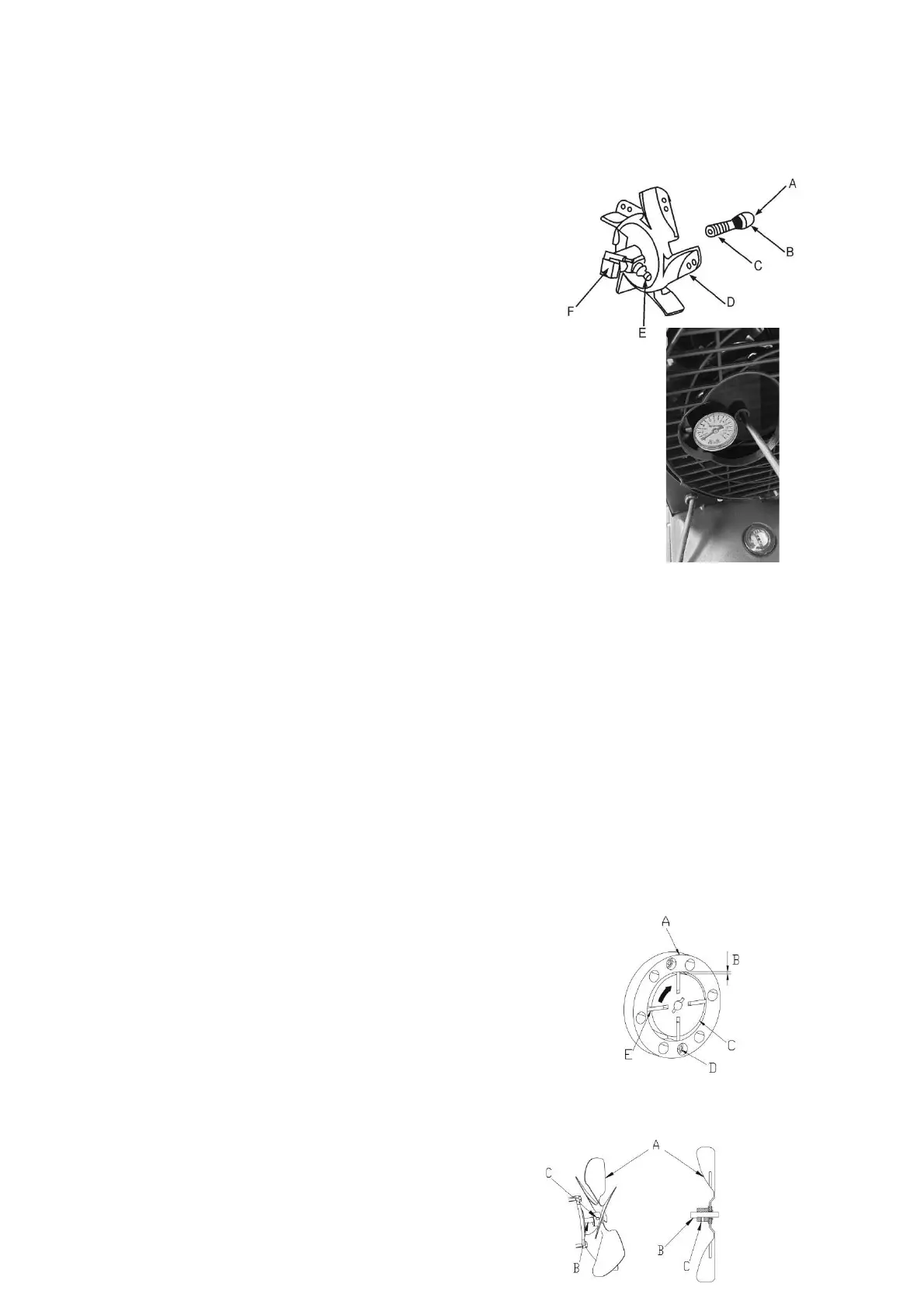

◆Assembling the oil nozzle

A. oil nozzle

B.nozzle core

C.seal ring

D.flame steady plate

E.air pipe fitting

F.Electrovalve Assy

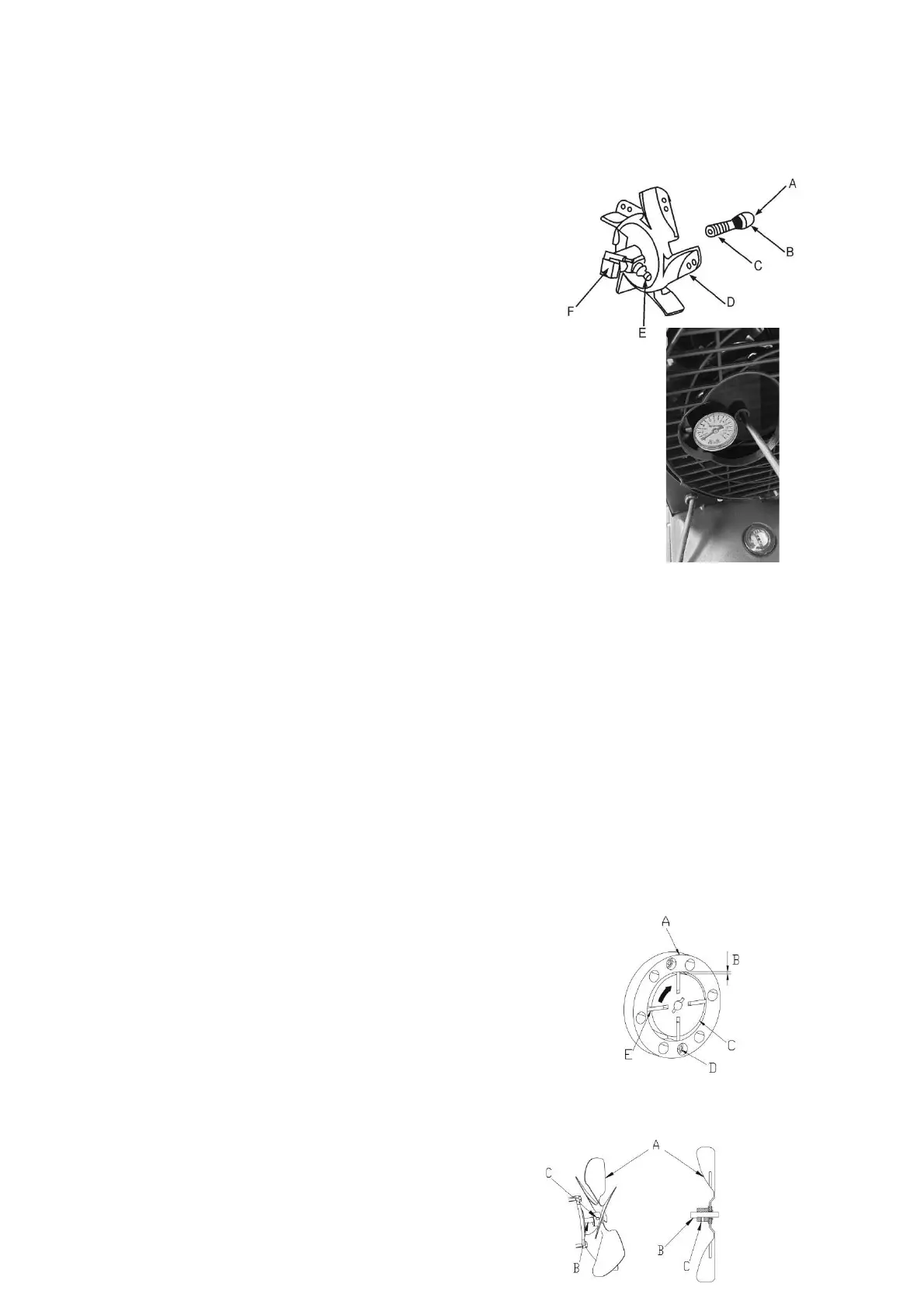

◆ Pressure adjustment

Kerosene = 3 bars

Diesel = 4 bars

Factory setting at 4 bar

◆

Air pump

By maintenance the air pump must be proper assembled, to prevent low air pressure or air leakage.

A. Pump blade

B. Pump cover

C. Air intake filter

D. Pressure cover

E. Air inlet guard

F. Air outlet filter

G. Pump core

H. Connecting part

I. Pressure gauge

◆ the match between the pump body and pump core

The four pump blades were set in the four grooves of the pump core,which move centrifugally

clockwise in the pump,the cooperation gap between the pump enclosure and the pump core should

be kept in 06~0.08mm,to ensure that the air pump can produce sufficient pressure.

A.pump body

B . gap 0.06~0.08mm

C.pump core

D.screw

E.pump blade

◆

fixation of the fan blades

Install fan blade on motor shaft und use set screw to tighten them firmly

A.fan blade

Loading...

Loading...