6

REDUCED CLEARANCES

Under certain conditions the minimum clearances

may be reduced by means of:

(a) The use of listed pipe shields, installed in

accordance with the manufacturer’s instructions.

(b) Shields constructed in accordance with

NFPA211 (USA), Can3-B365 installation code

for solid fuel fired appliances.

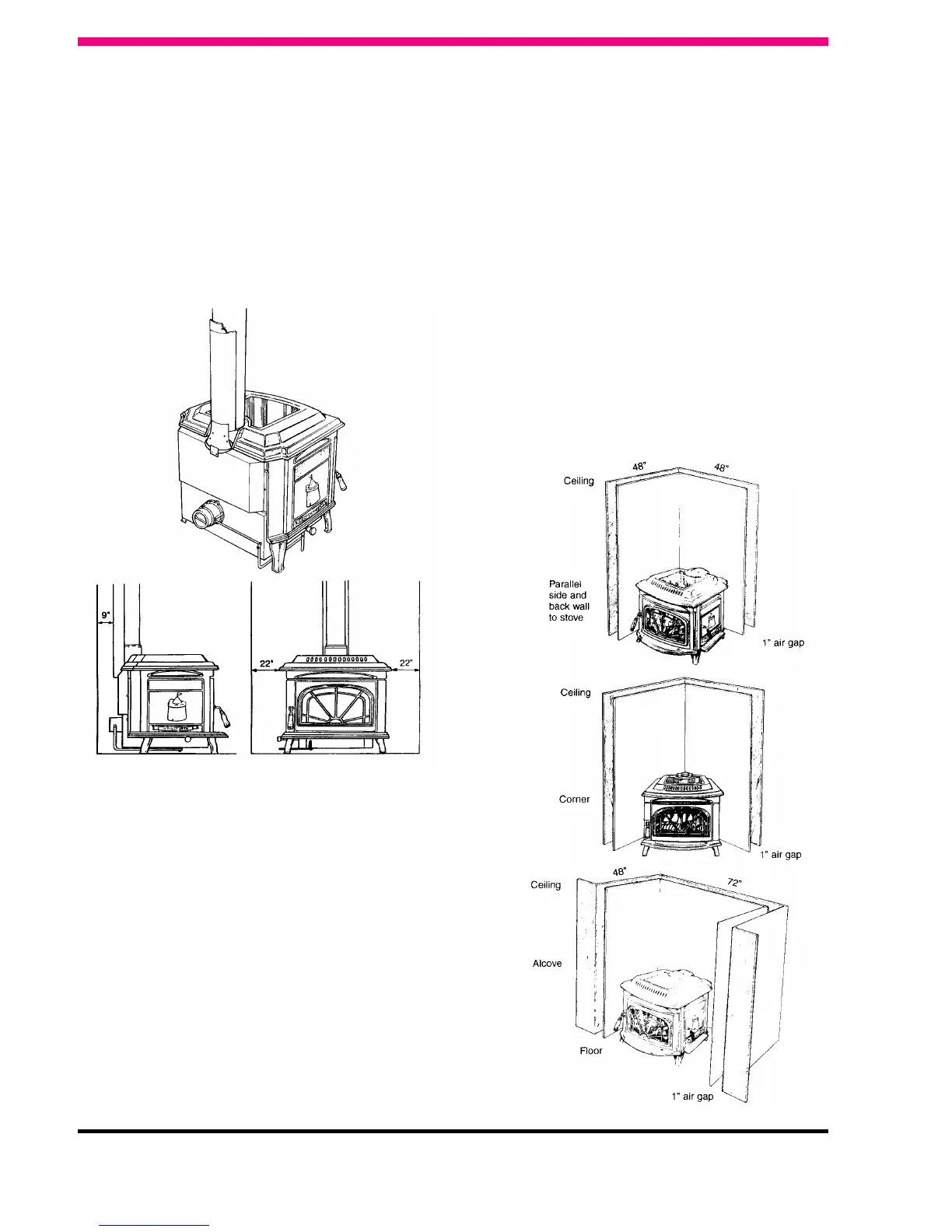

(c) When listed pipe shields are used - top exit

option only - the clearances may be reduced to

9” from the pipe shield and 11” from stove back.

DOUBLE WALL CONNECTIONS

Double wall chimney connectors may be substituted

for the shielded pipe provided it is UL/ULC listed for

a 9” clearance or less.

WALL PROTECTORS

Materials and products listed for the purpose of

reducing clearance to combustibles shall be

installed in accordance with the conditions of the

listing and the clearances may be reduced by the

percentage reduction as stated in the wall shield

manufacturer’s instructions.

For clearance reduction systems using an air space

between the combustible wall and the wall protector,

adequate air circulation shall be provided by one of

the following methods.

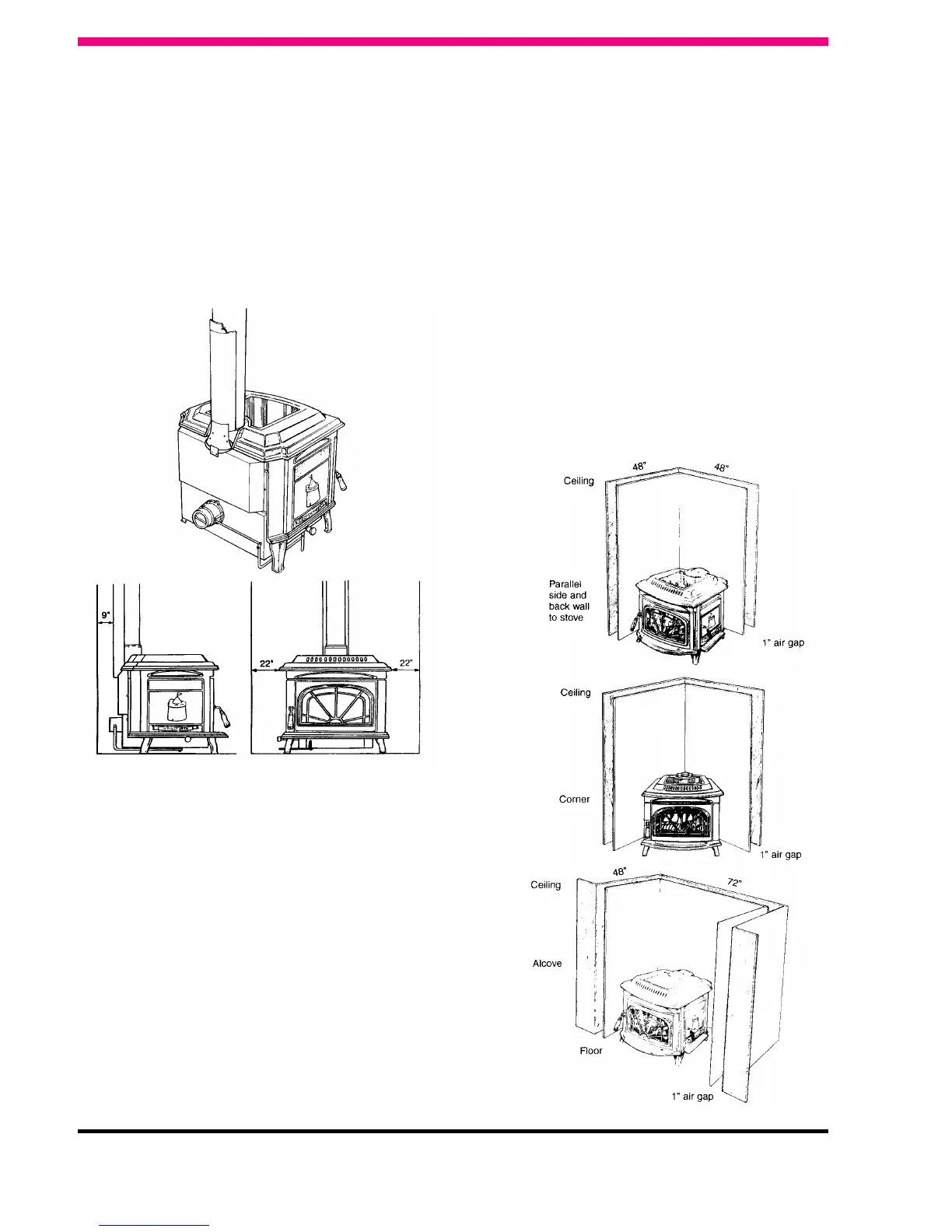

1. Adequate air circulation may be provided by

leaving all edges of the air protector open with at

least a 1” air gap.

2. If the wall protector is mounted on a single flat

wall, away from corners, an adequate air

circulation may be provided by leaving bottom

and top edges or only the side and top edges

open with at least a 1” air gap.

3. Wall protectors that cover two walls in a corner

shall be open at the bottom and top edges with

at least a 1” air gap.

4. All clearances shall be measured from the outer

surface of the combustible material to the

nearest point on the surface of the Waterford

Trinity MK II Stove disregarding any intervening

protection applied to the combustible material.

When using a manufactured wall shield system

observe local building codes and by-laws.

Fig.24

Fig.25

Fig.26

Fig.27

Fig.28

Fig.29

Loading...

Loading...