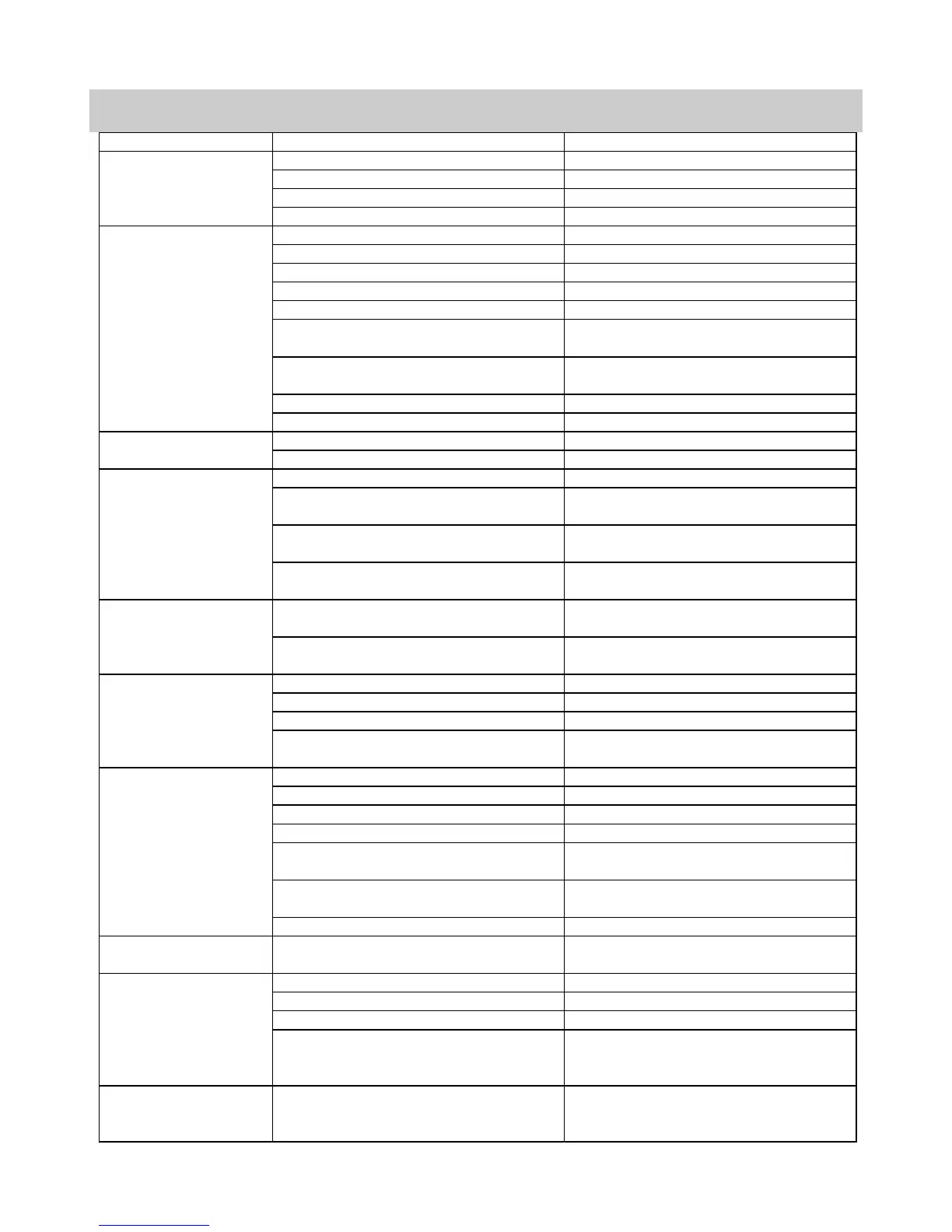

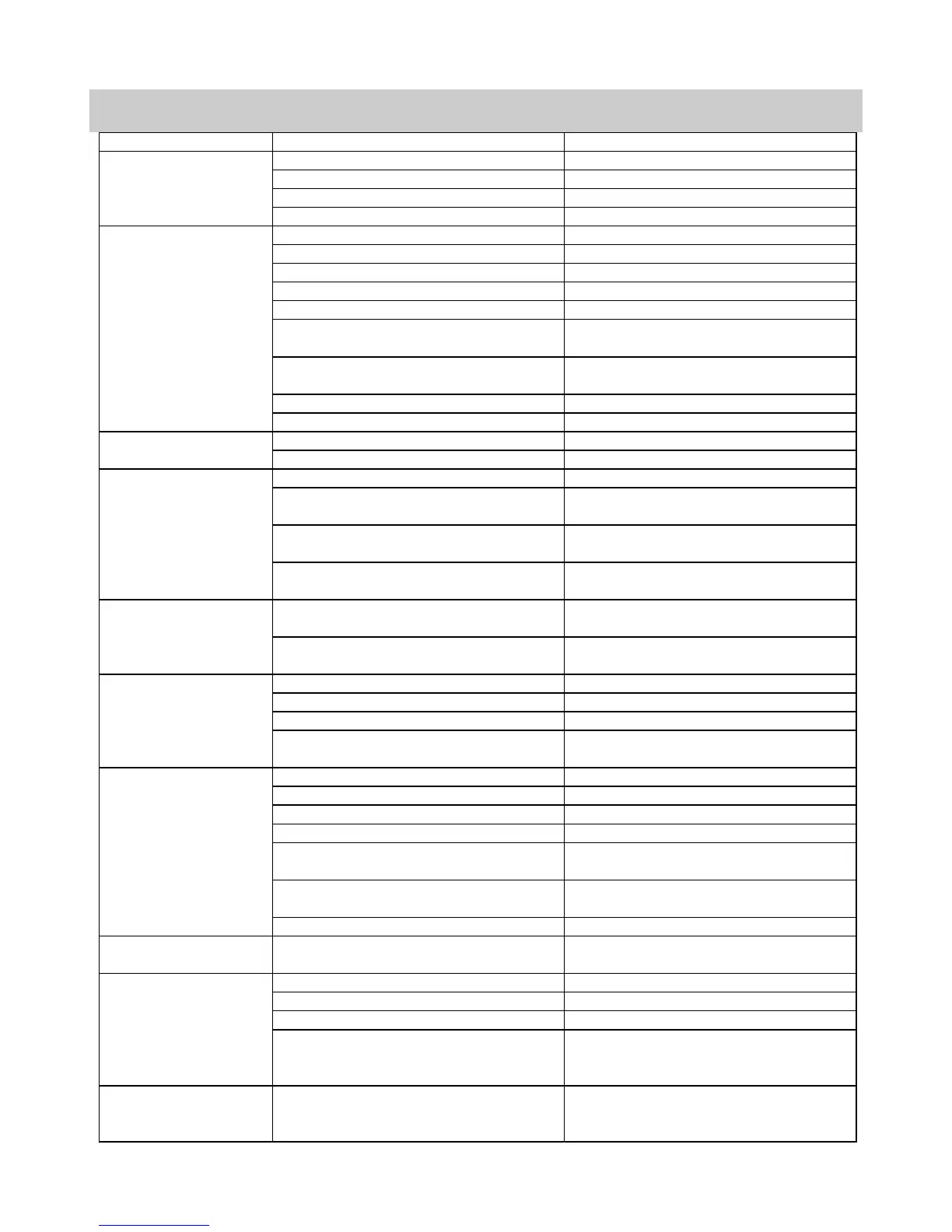

Trouble Shooting

Issue P ossibleCause PossibleSolution

1.Nopowersuppl y. Che ckelectricalservice,fuse,etc.

2.Defectivecircuitboard. Repl acefaultyparts.

3.Powerfailure. Resettimeofday.

4.Defectivemeter. Replaceturbinemeter.

1.By‐passval veopen. Closeby‐passvalve.

2.Outofsal torsaltlevelbelowwaterlevel. Addsalttotank.

3.Pluggedinjector/screen. Cleanparts.

4.Fl

o

wofwaterblockedtobri netank. Checkbrine tankre fillrate.

5.Hardwaterinhotwatertank. Repeatflushingofhotwatertankrequired.

6.Leakbetweenvalv eandcentraltube. Che ckifcentraltubeiscrackedoro‐ringis

damaged. Replacefaultyparts.

7.Internalvalveleak. Replacevalve seal s,spacer,andpi

ston

assembly .

8.Reservecapacitysettingtoolow. Increasereservecapacity.

9.Notenoughcapacity. Increasesaltdosage.

1.Refilltimeistoohigh. Che ckrefilltimesetting.

2.Defectiveflowcontrol. Repl ace.

1.Ironorscalebuildupinlinefeedingunit. Cleanpipe s.

2.Ironbuildupinsidevalve orta nk. Cleancontrolandaddresincleanertocle

an

bed.Increase regenerationfrequency.

3.Inle tofcontrolplu ggeddue toforeign

material .

Removepi stonandcleancontrolval ve.

4.Deterioratedresin.(Maybecausedfrom

highchlorineorchloramines.)

Re‐bedunit.Conside raddingcarbonpre ‐

treatment.

1.Airinwatersystem. Checkwel lsystemforproperaireliminator

control.

2.Incorrectdrainli

neflowcontrol(DLFC)

button.

Checkforproperflowrate.

1.Pluggedinjectororscreen. Cleanparts.

2.Valvenotregenerating. Replacecircuitboard,motor,orcontrol.

3.Foreignmaterialinbrinevalv e. Cl e anparts.

4.Unitnotdrawi ngbrine. Checkforvacuumleakinbrineline

connections.

1.Drainlineflowcontrolisplugged. Cleanparts.

2.Inje ctororsc

reenisplugged. Cle anparts.

3.Inle tpressuretoolow. Increasepressureto25PSI.

4.Internalvalveleak. Replaceseals, spacers,andpistonassembly.

5.Safetyvalveclosed. Checkforleakinbrinelineconnections.

Replacesafetyfloatassembl y .

6.Vacuumleakinbri neline. Checkforleakinbri nelineconnections.

Tightenallconnections.

7.Drai

nlinehaskinkinitorisblocked. Checkdrainline.

H.Valvecontinuousl y

cycles.

1.Defectivepositi onsensorPCB. Replacefaultyparts.

1.Valvesettingsincorrect. Checkvalve settings.

2.Foreignmaterialincontrolvalve. Cle ancontrol.

3.Internalleak. Replaceseal s,spacers,andpistonassembly.

4.Pistonisstuckinposition.Motormayhave

failedorgearsha

vejammedordise ngaged.

Checkforpowe rtomotor.Checkforloose

wire.Checkforjammedgearsorgears

disengaged.Replacefaultyparts.

J.Valvemakesbeeping

sound.

1.Thepistonhasnotadvancedtothenext

cyclepositi onproperly .

Checkforpowe rtomotor.Checkforloose

wire.Checkforj

ammedgearsorgears

disengaged.

I.Fl ow todrain

continuously.

G.Unitfailstodrawbrine.

A.Unitfailstoinitiatea

regenerationcycle.

B.Waterishard.

E.Resinindrainline.

C.Saltuseishigh.

D.Lowwaterpre ssure.

F.Toomuchwaterinbrine

tank.

21

Loading...

Loading...