2

Installation Instructions

Series 919 and LF919

1

⁄4" – 2" (8 – 50mm)

Air Gap

Strainer

Reduced Pressure Zone Assemblies

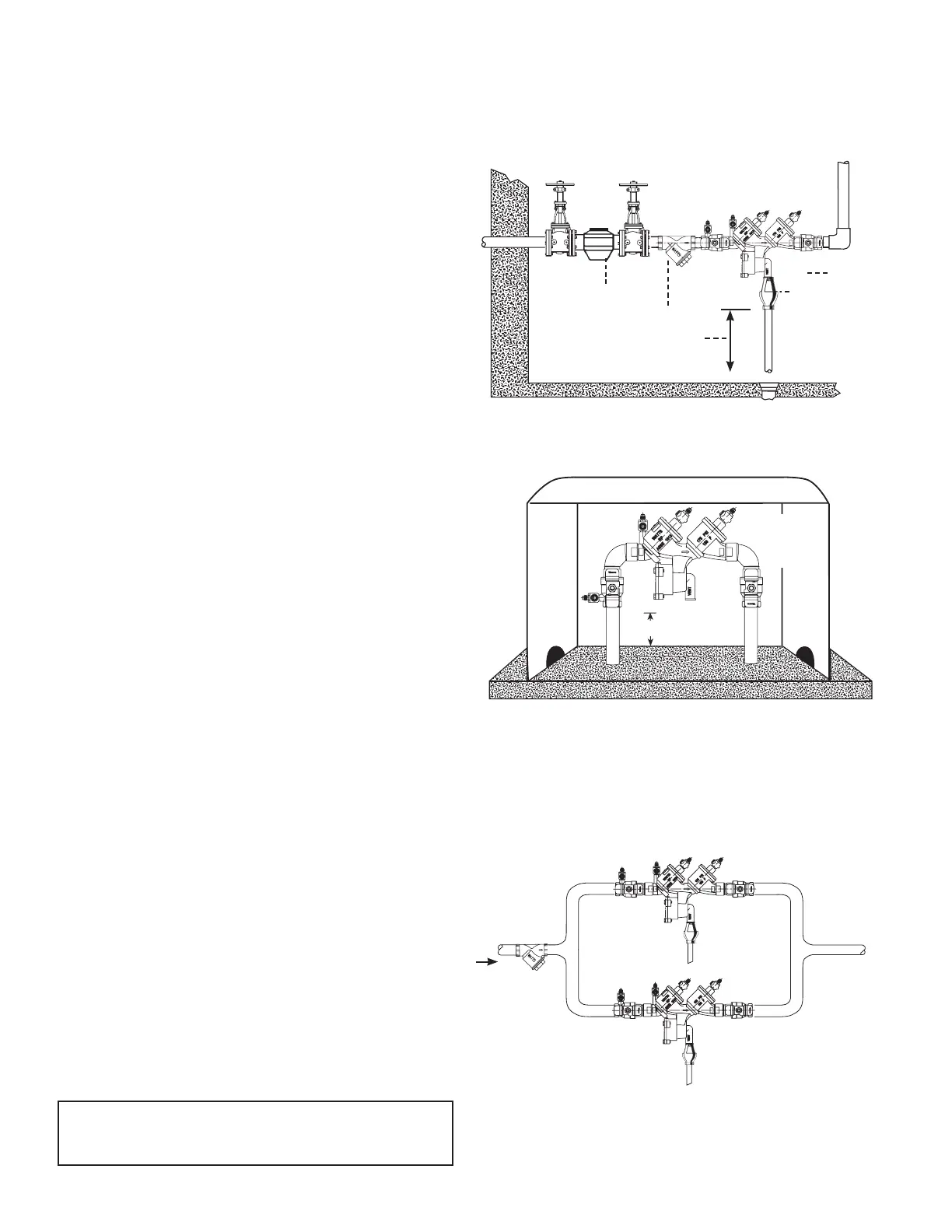

Indoor Installation

For indoor installations, make sure the Series 919 and LF919 is

easily accessible to facilitate testing and servicing. Do not install in

concealed locations. If the location of the Series 919 and LF919

is parallel and close to the wall, make sure the test cocks are eas-

ily accessible, and the drain line can adequately drain if required.

An air gap and drain line (see literature ES-AG/EL/TC) are piped

from the relief valve connection as shown, allowing evidence of

discharge to be clearly visible and preventing the occurrence of

water damage.

Outdoor, Above Ground Installation

For outdoor installations, it is recommended that you install the

Series 919 and LF919 where there are no freezing conditions and

above ground whenever possible.

You must install the Series 919 and LF919 in an accessible loca-

tion to facilitate testing and servicing. The installation must also

allow for adequate drainage from the air gap and the discharge

line if needed.

WARNING:

1. Do not allow the drain line to empty directly into a drainage

ditch, sewer system, or sump.

2. Do not install the Series 919 and LF919 in any location where

any part of the unit could become submerged in standing

water.

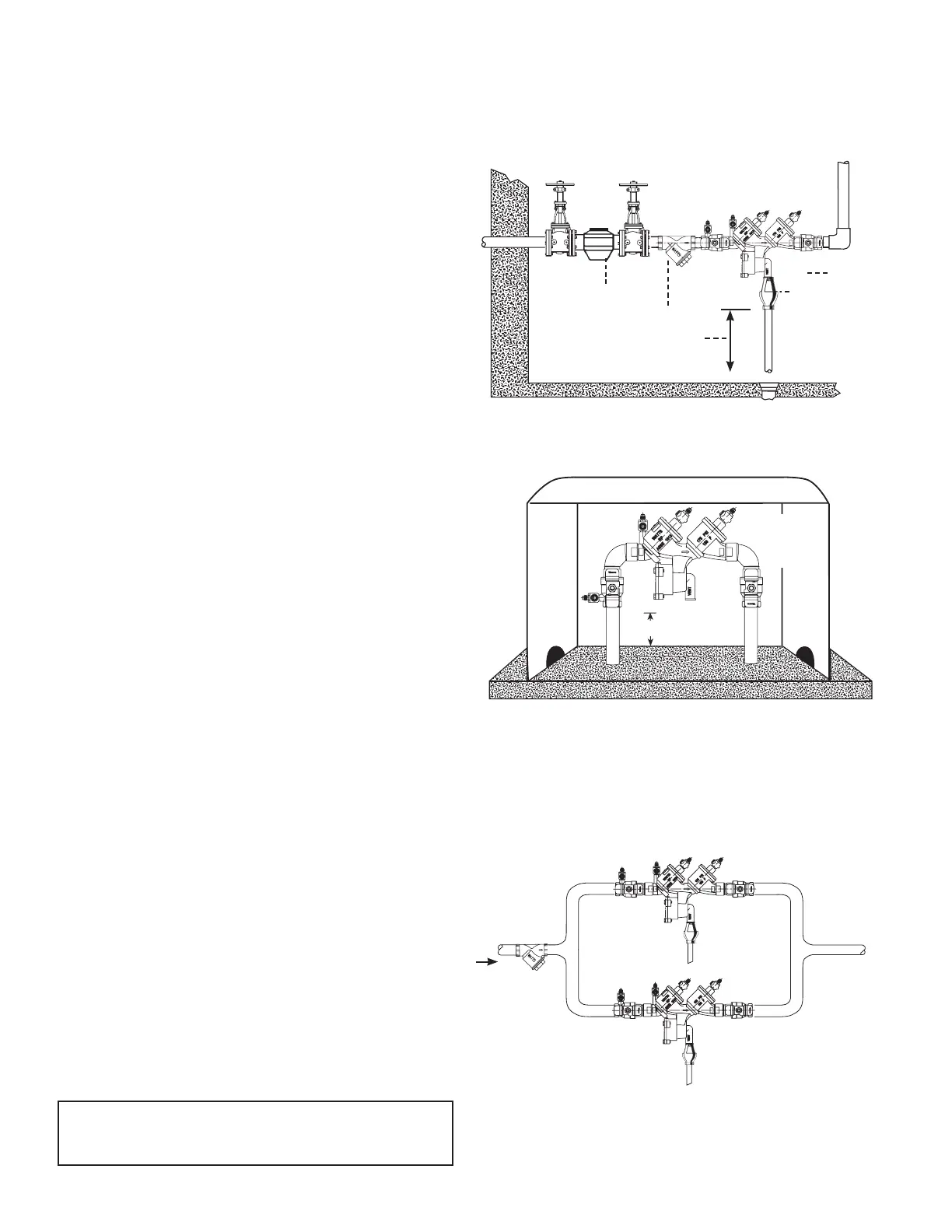

Parallel Installation

For parallel installations, you can install two or more small sized

Series 919's and LF919's (when approved) to serve a large supply

pipe main. You can use this type of installation in an application

where increased capacity beyond that provided by a single valve

is required. Additionally, this type of installation permits testing

and/or servicing of a single valve without shutting down the com-

plete line.

The number of Series 919 and LF919 units installed in parallel

should be determined by the engineer's judgement, based on the

operating conditions of a specific application.

NOTE: The total capacity of all the units installed in the application

should equal or exceed that required by the system.

Now available, Wa ttsBox Insulated Enclosures,

for more information, send for literature ES-WB.

FIBERGLASS WattsBox

Min. 12"

Annual inspection of all water system safety and control valves

is required and necessary. Regular inspection, testing and

cleaning assures maximum life and proper product function.

Meter

Indoor Installation

Outdoor Installation

Parallel Installation

12" (300mm) Minimum

(refer to local codes)

Watts

1

⁄4" – 2" (8 – 50mm) 919

Watts

1

⁄4" – 2"

(8 – 50mm)

919AQT

Watts

1

⁄4" – 2" 919

(8 – 50mm)

Min. 12" (300mm)

Loading...

Loading...