5.1

FACTORY

REPAIR

Wavetek

maintains

a factory repair

department

for

those

customers

not

possessing

the

necessary personnel

or

test

equipment

to

maintain

the

instrument.

If an

instrument

is

returned

to

the

factory

for

calibration

or

repair, a

detailed

description

of

the

specific

problem

should

be

attached

to

minimize

turnaround

time.

5.2

REQUIRED

TEST

EQUIPMENT

DVM (3%

digit)

Distortion

Analyzer

(

1%

F.S.)

HP334A

Oscilloscope

(~

40

MHz

bandwidth,

X

10 horizontal

magni-

fication,

de

triggering

to

1 Hz)

BNC

Termination

(500

~

1%,

~

1W)

Frequency

Counter

(6 digits, time base

accuracy~

50

ppm)

Low

Frequency

Spectrum

Analyzer

HP3580A

5.3

REMOVING

GENERATOR

COVER

For

main

board

access, remove

the

four

screws in

the

lower

cover, place

the

instrument

on

its

feet

and

lift

off

the

top

cover.

For

later access

to

the

synthesizer

board,

remove

the

four

screws from

the

inside corners

of

the

lower

board

that

attach

it

via

standoffs

to

the

lower cover.

Do

not

remove

the

lower

cover

unless necessary, because

it

supports

front

and

rear

panels.

SECTION

5

CALIBRATION

5.4

CALIBRATION

After

referring

to

the

following preliminary

data,

perform

calibration,

as necessary,

per

table

5-1.

If

performing

partial

calibration,

check

previous settings

and

adjustments

for

applicability.

1.

Unless

otherwise

noted,

all

measurements

made

at

the

500

OUT

connector

should

be

terminated

into

a

50U

(~

1%,

1W)

load.

2. Before

connecting

the

unit

to

an ac source,

check

the

ac

line

circuit

to

make sure

the

115/230

volt

switch

is

set

at

the

correct

position (see paragraph

2.2).

3.

Start

the

calibration by setting

the

front

panel

switches

as follows:

Dial

..................................

2.0

FREOMULT

.........................

X

1K

Mode (toggle switch) . . . . . . . . . . . . . . .

Toward

Dial

Digital

Switch

. . . . . . . . . . . . . . . . . . . . . . . .

0.1000

DC

OFFSET

...........................

OFF

Function

..............................

DC

AMPLITUDE

.

. . . . . . . . . . . . . . . . . . . . . . . . . ccw

ATTENUATION

..........................

0

4.

Allow

the unit to warm

up

at least

30

minutes for

final calibration.

Start

the calibration on main

board. All test points are located

on

the main

board.

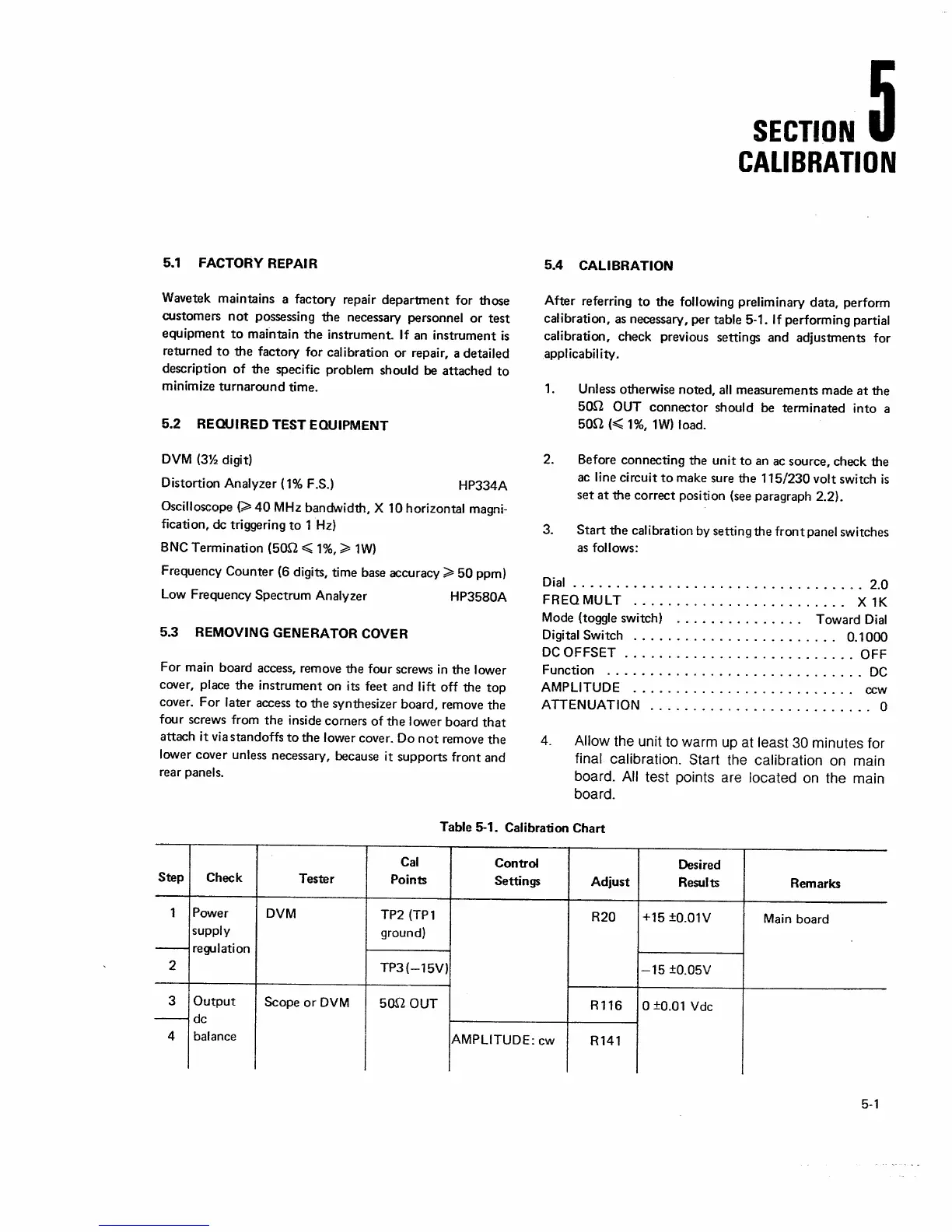

Table 5-1. Calibration

Chart

Cal

Control

Desired

Step

Check

Tester

Points

Settings

Adjust

Results Remarks

1

Power

DVM

TP2(TP1

R20

+15

±0.01V

Main

board

supply

ground)

-

regulation

2

TP3(-15V)

-15

±0.05V

3

Output

Scope

or

DVM

500

OUT

R116

0

±0.01

Vdc

-

de

4

balance

AMPLITUDE:

cw

R141

5-1

Loading...

Loading...