SECTION I

INSTALLATION

A. GENERAL

The

Wayne HSG200 and HSG400

power

gas

conversion burners are adaptable

to

most

types of

central heating

plants previously

fired by

power

oil

burners. Typical heating

plants

are

gravity

and forced

air circulation furnaces, hot water,

steam

or vapor

boilers.

Power

burner design makes the

HSG200

and

HSG400 well

suited

for "negative draft" fired

appliances where an oil burner

is

being replaced.

lnstallation of these

power

gas

conversion burner

models must conform to local

codes, or

in their

absence, the

American National

Standard

for the

Installation

of

Domestic

Gas Conversion

Burners.

ANS|Z21.8

-

and the National Flue

Gas Code,

ANSlZ223.1

or

current

standard

year.

NOTICE: ANSI

or

local installation

code compliance

is

the

sole

responsibility of the

qualified

installer.

VENTILATION

The HSG conversion burner models covered by this

manual shall

not

be

installed

in an appliance located

where

normal

air circulation or infiltration is

limited in

providing

all the air necessary for

proper

combustion

and draft hood dilution air.

ln

ooen

basements of homes of normal construction

(without

basement storm

windows

or tight stair doors)

infiltration

of combustion air

is

usually sufficient

to

replace that drawn up the

flue,

so special

provisions

are

seldom

necessary.

When

the

heating

appliance

is installed in

a

tightly

closed

room without

ventilation

openings to outdoors, or other

rooms,

provisions

shall

be made for

supplying air

for

combustion through special

openings,

one

near the floor

line

and the other

near

the ceiling. Each is to be

sized

on the basis of one square

inch

(645.2mm')

or more of

free

area each

1,000 BTU

(.29kW)

input

per

hour.

When

the building

is

of unusually tight construction,

has

kitchen and/or bathroom

ventilation

fans which may be

used for

exhausting air

to

outdoors, or

has

a

vented

fireplace, it is recommended that combustion air be

supplied

to the furnace room through intakes extending

to

the

outside

of

the

building and terminating

in

down

turned

fittings,

suitably arranged to

prevent

obstruction

from

snow

or

rain,

and including a

protecting

screen

not

smaller than

1/4 inch

(6.35mm)

mesh.

HEATING APPLIANCE INSPECTION

Clean

the

appliance

heat

exchanger

interior,

combustion

chamber and

flue

connections.

Remove

all

adhering tars, scale, dirt and

soot.

lnspect the heat

exchanger

for

obvious and

potential

flue

gas

leaks.

Cement all

joints

around the

appliance base

and

access openings to

prevent

air

and/or

flue

gas

leakage

into

or out of the combustion chamber.

Warm Air Furnaces*

-

Make

certain the electrical

characteristics of the

fan

and

limit

switch correspond to

those

required

by this burner and that

they are

in

proper

working

order.

Hot

Water

Boilers*

-

Make

certain water temperature

and altitude

gauges,

pressure

relief

valves are in

proper

working

order.

Steam

Boilers*

-

Make certain the system is

pressure

tight, and that the

pressure gage

and

pop

off

safety

valve

are in

proper

working

order.

Existing water

sight

glass

permits

clear observation of boiler water level.

*Where

applicable,

existing temperature

of

pressure

limit

switch or

low water cut-off

switch

operation and

electrical characteristics

shall

be checked to determine

their compatibility to the

gas

control circuitry of this

burner.

D.

CHIMNEY,

FLUE PIPE AND DRAFT CONTROL

The chimney should be

inspected

for unsafe

conditions such as excessive soot accumulation,

deteriorated

masonry,

blockage or

potential

blockage.

NOTICE: No manually adjustable flue

pipe

damper is

permitted

on any

gas

burner

installation.

The chimney

should

be lined

with

a corrosion resistant

material,

lf the chimney

is

unlined, consult

your

local

gas

utility for recommendations.

WARNING:

Under

no circumstances

should

the flue

pipe

be connected to

the

chimney of an open

fireplace.

The flue

pipe

should

be

sized

to carry of the flue

gases

as

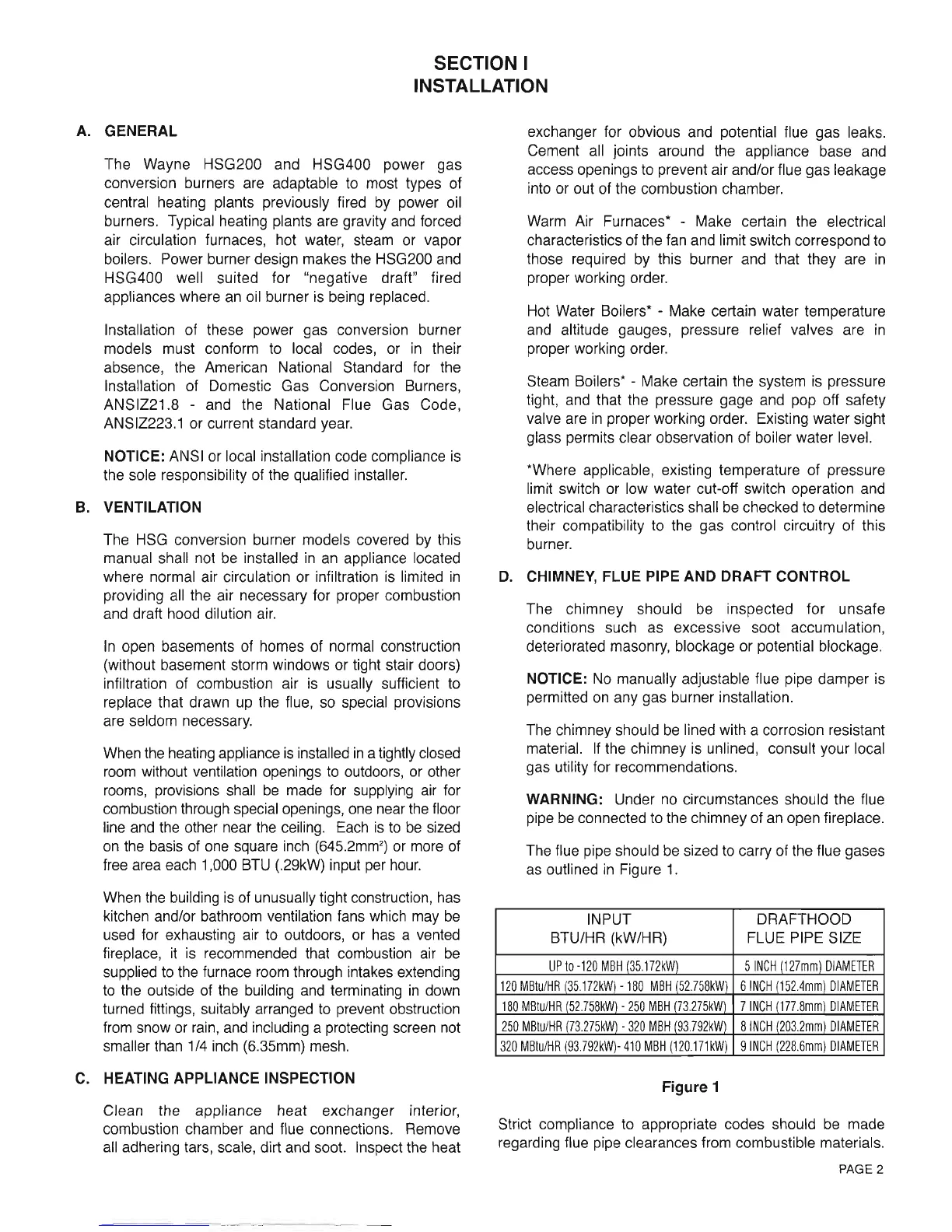

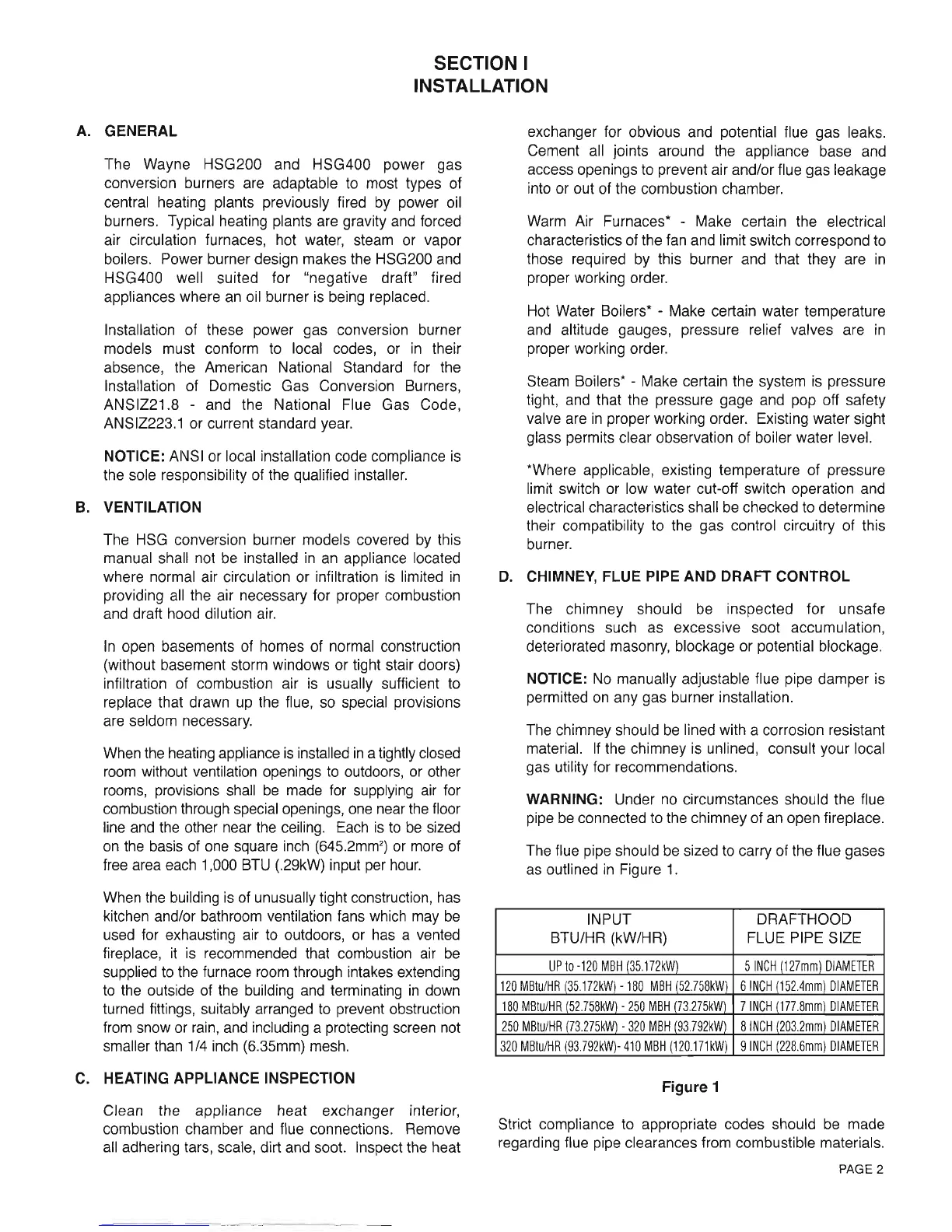

outlined in Figure 1.

Figure 1

Strict compliance

to

appropriate

codes

should

be made

regarding flue

pipe

clearances

from

combustible

materials,

B.

INPUT

BTU/HR

(kW/HR)

DRAFTHOOD

FLUE PIPE

SIZE

UP to -120 MBH

(35.172kW)

5 INCH

(127mm)

DIAMETER

120 MBtu/HR 135172kM

-

180 MBH

(52.758kW)

6 INCH

(152.4mm)

DIAMETER

180

MBtu/HR

(52.758kM

-

250

MBH

(73.275kW)

7 INCH

{177.8mm)

DIAMETER

250 MBtu/HR f3.275k$ - 320 MBH {93.792kW)8 INCH

(203.2mm)

DIAMETER

320 MBtu/HR

(93

792kW)- 410 MBH

(120.171kW)

I INCH

(228.6mm)

DIAMETER

c.

PAGE 2

SECTION I

INSTALLATION

A.

GENERAL

The Wayne HSG200 and HSG400 power gas

conversion burners are adaptable to most types of

central heating plants previously fired by power oil

burners. Typical heating plants are gravity and forced

air circulation furnaces, hot water, steam or vapor

boilers. Power burner design makes the HSG200 and

HSG400 well suited for "negative draft" fired

appliances where

an

oil burner

is

being replaced.

Installation of these power gas conversion burner

models must conform to local codes, or

in

their

absence, the American National Standard for the

Installation of Domestic Gas Conversion Burners,

ANSIZ21.8 - and the National Flue Gas Code,

ANSIZ223.1 or current standard year.

NOTICE:

A1'JSI

or local installation code compliance

is

the sole responsibility of the qualified installer.

B.

VENTILATION

The

HSG

conversion burner models covered

by

this

manual shall not

be

installed

in

an

appliance located

where normal air circulation or infiltration

is

limited

in

providing

all

the air necessary for proper combustion

and draft hood dilution

air.

In

open basements of homes of normal construction

(without basement storm windows or tight stair doors)

infiltration of combustion air

is

usually sufficient to

replace that drawn

up

the flue,

so

special provisions

are seldom necessary.

When the heating appliance

is

installed

in

a tightly closed

room

without ventilation openings to outdoors, or other

rooms,

provisions shall

be

made

for

supplying air for

combustion through special openings,

one

near

the

floor

line and the other near

the

ceiling.

Each

is

to

be

sized

on

the

basis of

one

square

inch

(645.2mm

2

)

or more of

free

area each 1,000

BTU

(.29kW) input per

hour.

When

the

building

is

of unusually tight construction, has

kitchen and/or bathroom ventilation fans which may

be

used for exhausting air to outdoors, or has a vented

fireplace,

it

is

recommended that combustion air

be

supplied to the furnace room through intakes extending

to

the outside of

the

building

and

terminating

in

down

turned fittings, suitably arranged to prevent obstruction

from snow or

rain,

and

including a protecting screen not

smaller than 1/4 inch (6.35mm) mesh.

C.

HEATING APPLIANCE INSPECTION

Clean the appliance heat exchanger interior,

combustion chamber and flue connections. Remove

all

adhering tars, scale, dirt and soot. Inspect the heat

exchanger for obvious and potential flue gas leaks.

Cement all joints around the appliance base and

access openings

to

prevent air and/or flue gas leakage

into or out of the combustion chamber.

Warm Air Furnaces* - Make certain the electrical

characteristics of the fan and limit switch correspond to

those required

by

this burner and that they are

in

proper working order.

Hot Water Boilers* - Make certain water temperature

and altitude gauges, pressure relief valves are

in

proper working order.

Steam Boilers* - Make certain the system

is

pressure

tight, and that the pressure gage and pop off safety

valve are

in

proper working order. Existing water sight

glass permits clear observation of boiler water level.

*Where applicable, existing temperature of pressure

limit switch or low water cut-off switch operation and

electrical characteristics shall

be

checked to determine

their compatibility to the gas control circuitry of this

burner.

D.

CHIMNEY, FLUE PIPE AND DRAFT CONTROL

The chimney should be inspected for unsafe

conditions such as excessive soot accumulation,

deteriorated masonry, blockage or potential blockage.

NOTICE:

No

manually adjustable flue pipe damper is

permitted

on

any gas burner installation.

The chimney should

be

lined with a corrosion resistant

material.

If

the chimney

is

unlined, consult your local

gas utility for recommendations.

WARNING: Under

no

circumstances should the flue

pipe

be

connected to the chimney of

an

open fireplace.

The flue pipe should

be

sized

to

carry of the flue gases

as

outlined

in

Figure

1.

INPUT DRAFTHOOD

BTU/HR (kW/HR) FLUE PIPE SIZE

UP

to

-120

MBH

(35.172kW)

51NCH

(127mm)

DIAMETER

120

MBtu/HR

(35172kW)

-180

MBH

(52.758kW)

6

INCH

(152.4mm)

DIAMETER

180

MBtu/HR

(52.758kW)

-

250

MBH

(73.275kW)

7

INCH

(177.8mm)

DIAMETER

250

MBtu/HR

(73.275kW)

-

320

MBH

(93.792kW)

8

INCH

(203.2mm)

DIAMETER

320

MBlu/HR

(93.792kW)-

410

MBH

(120171

kW)

9

INCH

(228.6mm)

DIAMETER

Figure 1

Strict compliance to appropriate codes should

be

made

regarding flue pipe clearances from combustible materials.

PAGE 2

Loading...

Loading...