WAYNE COMBUSTION SYSTEMS

801 GLASGOW AVE.

FORT WAYNE, IN 46803

PHONE: (260) 425-9200

(855) WAYNECS

(800) 443-4625

FAX: (260) 424-0904

www.waynecombustion.com

Manual 62484 | Revision D | Publication Date: 4/25/2018

Note: Dimensions in parentheses ( ) are informational only. English values take priority.

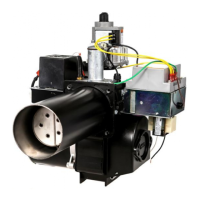

BURNER MODELS MINIMUM INPUT MAXIMUM INPUT Air Tube Standard Lengths

HSG200 60,000 Btu/hr (18 kW) 200,000 Btu/hr (59 kW) 6, 9,12 in. (153, 229, 305 mm)

HSG400 200,000 Btu/hr (59 kW) 400,000 Btu/hr (117 kW) 6, 9,12 in. (159, 229, 305 mm)

FUELS: Natural Gas and LP Gas FLAME SAFETY: 24 Vac Electronic IGNITION: 7300 Vac Direct Spark

AVAILABLE VOLTAGES: 120 Vac 60 Hz, 230 Vac 50/60 Hz 1 Phase

AIR TUBE DIAMETER: 4 in (101.6 mm) MOUNTING: Adjustable Flange is standard; Pedestal Mount is Optional

CSA CERTIFICATION:

189810-1154925

ANSI Z21.17

MASS G3-0903-67

READ THIS MANUAL BEFORE USING THIS PRODUCT. FAILURE TO FOLLOW THE

INSTRUCTIONS AND SAFETY PRECAUTIONS IN THIS MANUAL CAN RESULT IN

SERIOUS INJURY OR DEATH. KEEP THIS MANUAL FOR FUTURE REFERENCE.

INSTALLTION OF THE BURNER MUST BE DONE BY A QUALIFIED INSTALLER IN

ACCORDANCE WITH REGULATIONS OF THE NATIONAL FUEL GAS CODE ANSI

Z223.1/NFPA54, AND IN COMPLETE ACCORDANCE WITH ALL LOCAL CODES AND

AUTHORITIES HAVING JURISDICTION.

A QUALIFIED INSTALLER IS THE PERSON WHO IS RESPONSIBLE FOR THE

INSTALLATION AND ADJUSTMENT OF THE EQUIPMENT AND WHO IS LICENSED

TO INSTALL GAS-BURNING EQUIPMENT IN ACCORDANCE WITH ALL CODES AND

ORDINANCES.