R660系列柴油机维修保养手册

--

Maintenace Manual For R660 Series Diesel Engine

清洗针阀偶件必须在清洁的环境中

进行,不能使零件沾上任何的脏污。

The needle valve and seat assembly should

be cleaned in clean environment to ensure

no dirt on parts.

首先,将喷油器外表面的污物和积

碳清除干净,应注意只允许用汽油或煤

油将污物和积碳泡溶,或用软质木板擦

拭,禁用刮刀、锉刀及砂纸,也不允许用

棉纱擦拭。

At first, dirt and carbon deposit on injector

surface should be removed. During

removing, the injector must be soaked in

petrol or kerosene, then scrape the dirt with

soft wooden plate. Scraper, file, sand paper

and cotton yarn are forbidden.

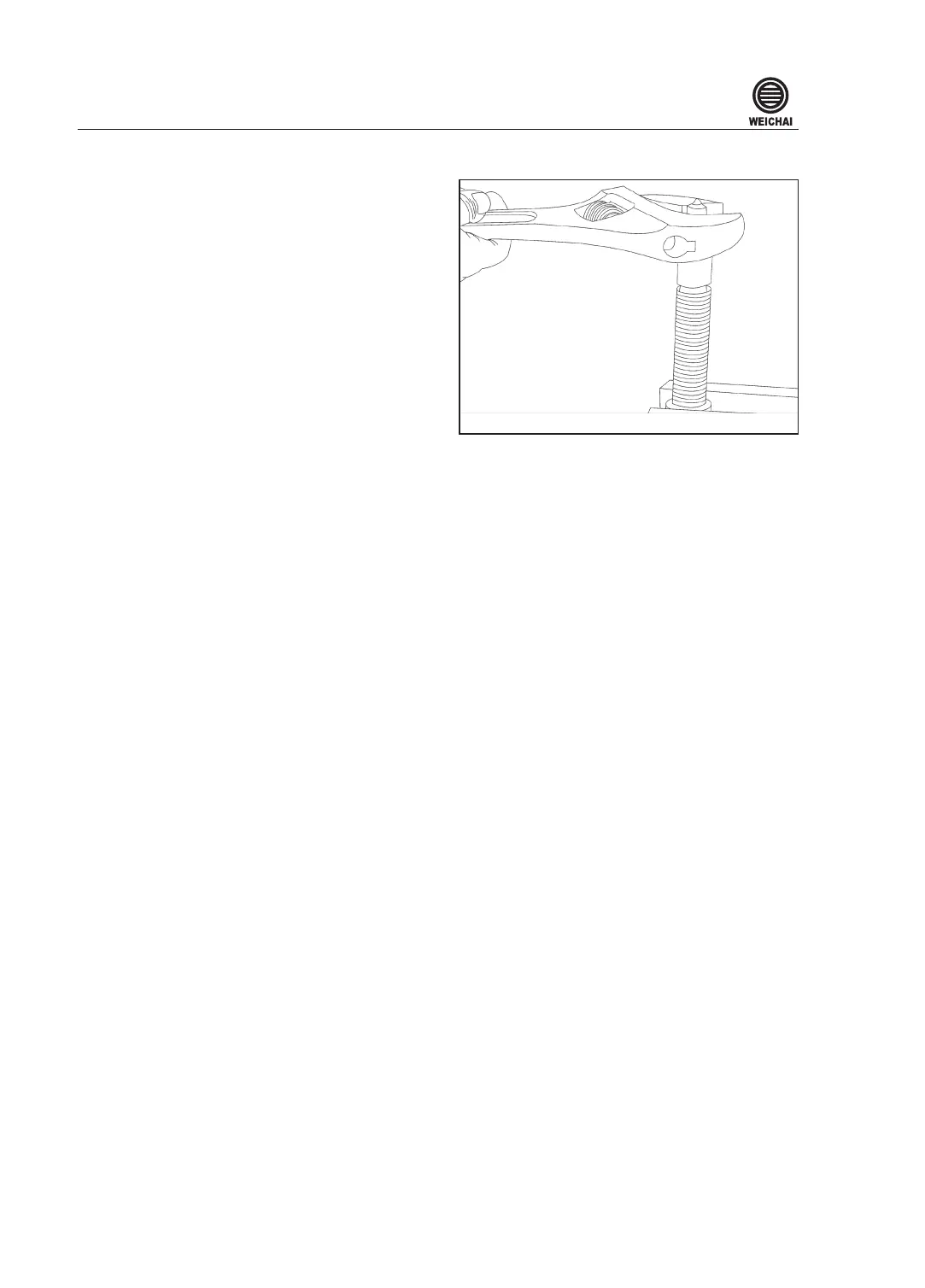

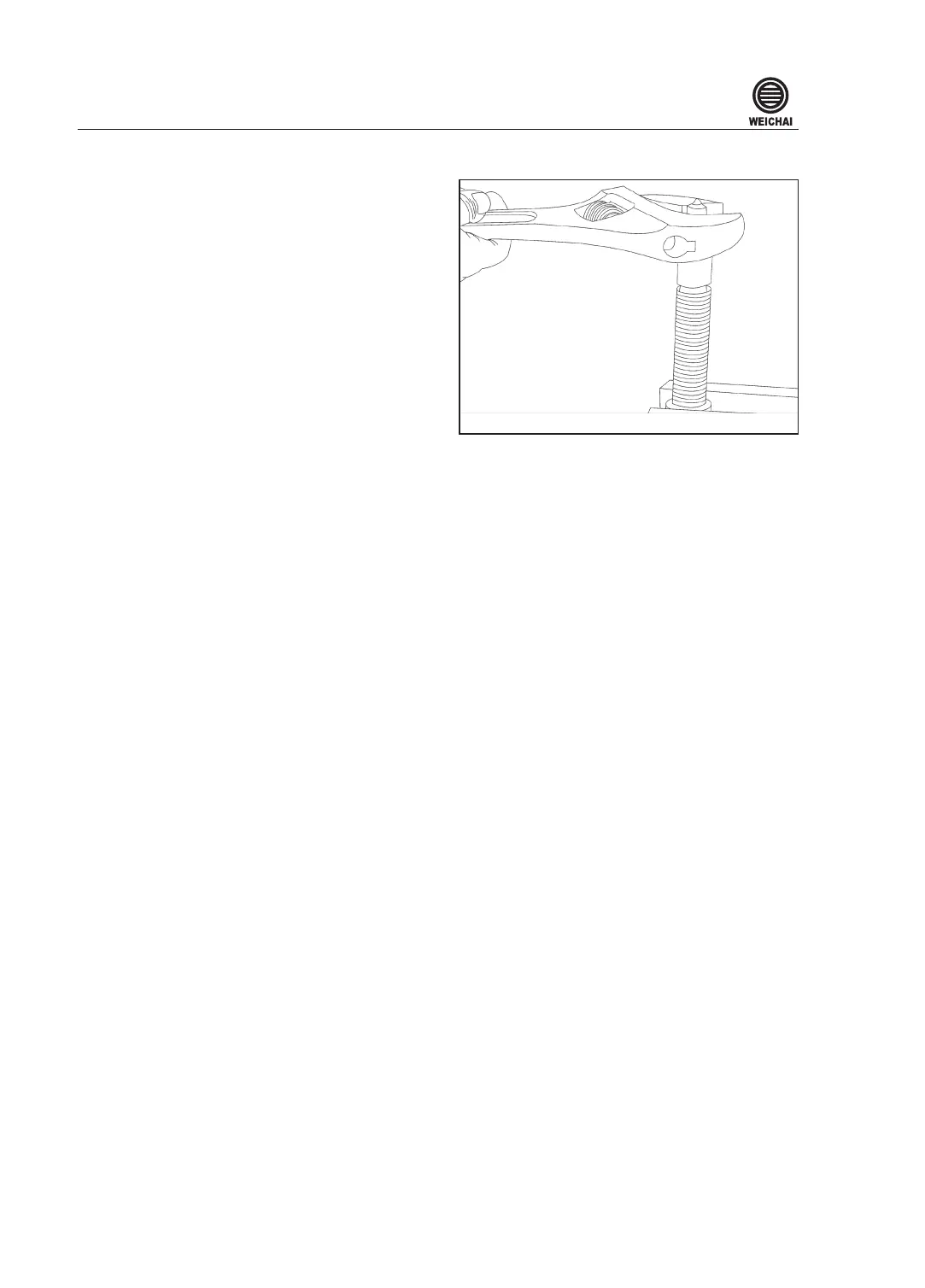

夹紧喷油器体,松开紧帽,取出针阀

体和针阀,放入干净汽油或煤油中清洗

(偶件不能互换,应注意配对)。

Then grip injector with pliers, loosen the

screw, take out needle valve and valve body

(mated couple can not be exchanged), wash

them in clean petrol or kerosene.

检查喷油压力

Check injection pressure:

把压力试验器断开,压手柄若干次,然后接通试验器,慢慢压手柄直到带轻微喷射声的燃油从

喷油嘴喷出,指示的压力即为喷油压力。

Disconnect the pressure tester and push the handle several times, and then connect the tester again, push

the handle slowly until fuel ejects from nozzle with slight jetting sound. The pressure indicated now is

injection pressure.

新喷油器或新的喷油器弹簧最低 250bar。若测得的喷油压力低于此值,可通过更换调整垫片

来调整,大约每加厚 0.01mm,喷油压力上升 1bar。

The minimum injection pressure for new injector or injector spring is 250bar. If the measured injection

pressure is less than this value, adjust it with shims. A 0.01mm increment of thickness will increase the

pressure by 1bar.

Loading...

Loading...