--

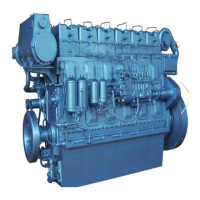

R660系列柴油机维修保养手册

Maintenace Manual For R660 Series Diesel Engine

1.2 燃油供给系统故障

Fuel Supply System Failure

燃油供给系统故障表现为燃油系统不供油或供油不正常,柴油不着火或着火后不能转入正常

运转。

Fuel supply system failure exhibits that fuel system fails to supply fuel or supplies fuel improperly, fuel

does not ignite, or engine cannot be turned into normal operation after ignition.

故障原因

Cause

排除办法

Remedy

(1)燃油管路堵塞

Fuel pipeline clogged.

(1)检查管路并清洗畅通

Check and clean pipeline.

(2)燃油滤清器堵塞

Fuel filter clogged.

(2)清洗滤清器,必要时更换滤芯

Clean diesel fuel filter, and replace filter element if

necessary.

(3)燃油系统内有空气

Air in fuel system.

(3)检查燃油管路接头是否松弛,旋开各部件

放气螺塞,排除内部空气。

Check joints of fuel pipeline for proper connection,

unscrew various air bleed plugs to bleed air.

(4)输油泵不供油或断续供油

Fuel supply pump fails to supply or supplies fuel

intermittently.

(1)检查输油泵进油管是否漏气,或检修输油

泵

Check fuel inlet pipe of fuel supply pump for air

leakage, or check and repair fuel supply pump.

(5)喷油泵故障:

供油提前角不正确

喷油泵弹簧断裂

喷油泵齿条卡死在停车位置

出油阀卡住或出油阀弹簧断

Injection pump fails:

Incorrect fuel supply advance angle.

Injection pump spring broken.

Injection pump pinion rack got stuck in stop

position.

Delivery valve stuck or delivery valve spring

broken.

(2)

重新调整供油提前角

更换弹簧

检修或更换

拆检清洗或更换出油阀及弹簧

Readjust fuel supply advance angle.

Replace spring.

Repair or replace.

Remove, clean or replace delivery valve and spring.

(6)喷油器故障

喷油器喷孔堵塞

喷油器针阀卡死

喷油压力太高或太低

Fuel Injector Failure

Fuel injector nozzle orifice clogged.

Fuel injector needle valve stuck.

Fuel injection pressure too high or too low.

(6)

清洗喷油嘴或更换

拆检清洗并研修喷油嘴偶件或更换新偶件

调整喷油器喷油压力

Clean or replace fuel injection nozzle.

Remove, clean and/or repair, or replace fuel

injection nozzle coupling piece.

Adjust fuel injector's injection pressure.

Loading...

Loading...