Operation and Maintenance Manual

of WP12C Series Marine Diesel Engine

Note˖ķ Angle value is the angle to be tightened after the specified torque

is obtained.

ĸ There are corresponding requirements for strength rating of all bolts and nuts

used on this engine. The bolts and nut with the same specifications but with

different strength rating are not allowed to misfit and exchange.. It is not allowed to

exceed the limit of reusing timesˈotherwise it will cause serious consequence.

3.6 Operation Requirements of Diesel Engine

3.6.1 Depreservation work of new diesel engine

After the diesel engine container is unpackedˈthe user first should check

diesel engine and accessories according to packing list provided in deliveryˈ

check the exterior of diesel engine for damageˈconnection parts for

loosenessˈthen carry out the work as follows˖

(1) Wipe off the antirust coat of exposed parts and anti-corrosion agent, etc.

(2) Drain the preservation oil from the inside of fuel filter and fuel system compo-

nents (it is also allowed to start engine without draining the preserving oil from fuel

systemˈbut to run engine with load is allowed only when the preserving oil in fuel

system is consumed and the normal diesel fuel is delivered.)

However, the preservation period of diesel engine is one year. When the

preservation period exceeds one year, conduct inspection and adopt neces-

sary supplementary measures.

(3) Turn the flywheel and inject the solvent into intake pipe, until the

preservation oil inside cylinder is completely expelled.

(4) Inject the solvent into supercharger inlet and exhaust ports, until

the preservation oil inside is completely expelled.

(5) Add oil to diesel engine oil sump as specified.

(6) Fill the diesel engine cooling system with coolantˈthe coolant

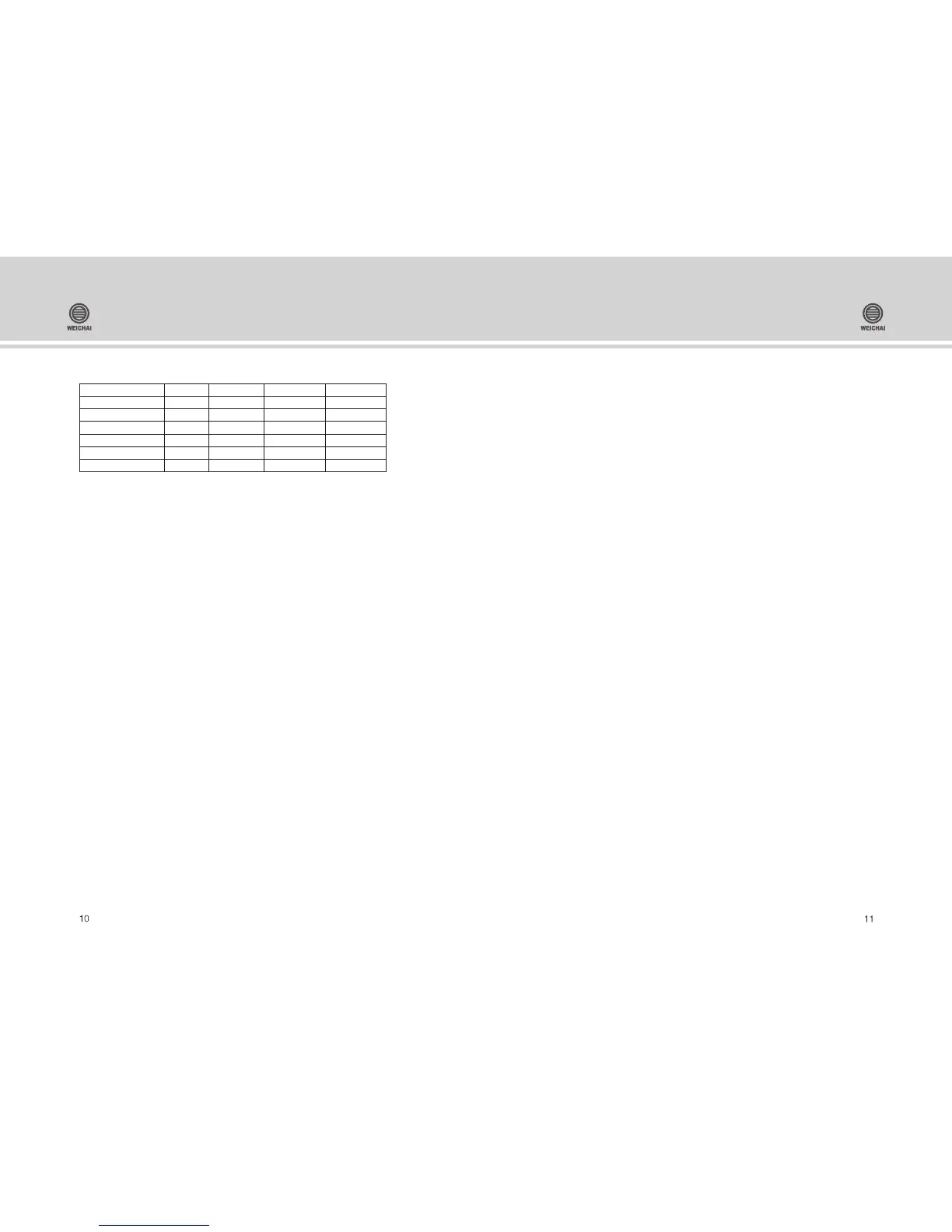

Camshaft gear bolt

Piston cooling injector bolt

Exhaust manifold bolt

Standard M6 bolt

Standard M8 bolt

Standard M10 bolt

Standard M12 bolt

M8-8.8 8˪.+120° 30 2

M10 30˪. 25

M10 15˪.+60° 65 2

8.8 8˪. 10.9 13˪.

8.8 22˪. 10.9 31˪.

8.8 39˪. 10.9 58˪.

8.8 70˪. 10.9 100˪.m

is demineralized fresh water or coolant with anti freeze additive. It is forbidden

to add sea water into cooling system.

3.6.2 Check and Preparation Prior to Starting

(1) Check the coolant level

The cooling level can be seen through glass inspection hole on the expansion

water tankˈif the coolant is not enoughˈopen the coolant filler cap to fill the

coolant. It is forbidden to add a large quantity of coolant while engine is in hot

state, because a great thermal change will damage the parts. If in an emergency

case there is no coolantˈit is allowed to slowly to add cold water with tempera-

ture not too low from the coolant fillerˈuntil the coolant is over-flown.

(2) Check the fuel level

(3) Check the engine oil level

Oil level should be at between the upper scale mark and lower scale marks of

the oil dipstickˈif necessary, add engine oil from the oil filler on the engine body.

(4) Check whether the connection of diesel engine accessories is reliableˈand

eliminate the abnormal phenomenon. Check whether the circuit wiring of start

system is normalˈand battery is adequately charged. Then open the valve of fuel

tankˈuse the hand pump on the delivery pump to expel air out of the fuel system.

3.6.3 Starting Diesel Engine

Turn on the instrument power switchˈset the throttle lever to a large fuel

quantity positionˈpush the starting buttonˈand if the engine is not started in 5

10 sec., repeat the above starting procedure about 1 min later. However, if

engine fails to start successively for three timesˈstop the startingˈfind out the

causes and eliminate the failure, and then make another attempt for the starting.

With the engine startedˈrelease the button immediately, and at the same

time, pay attention to readings of various instruments, the oil pressure gauge

should indicate pressure at once. Do not let the cold engine run at high speedˈ

it is required to run the engine at idle speed for a period of time, but the running

at idle speed should not be too long.

3.6.4 Stopping Diesel Engine

Before stopping engineˈfirst remove the loadˈthen reduce the engine speed

to 6001000rpmˈand wait a few minutes later, move the stop control handle to

shutdown the engine. After stopping, turn off the power of instrument.

Operation and Maintenance Manual

of WP12C Series Marine Diesel Engine

Loading...

Loading...