Weichai America Corp.

Revision: October 2018 25

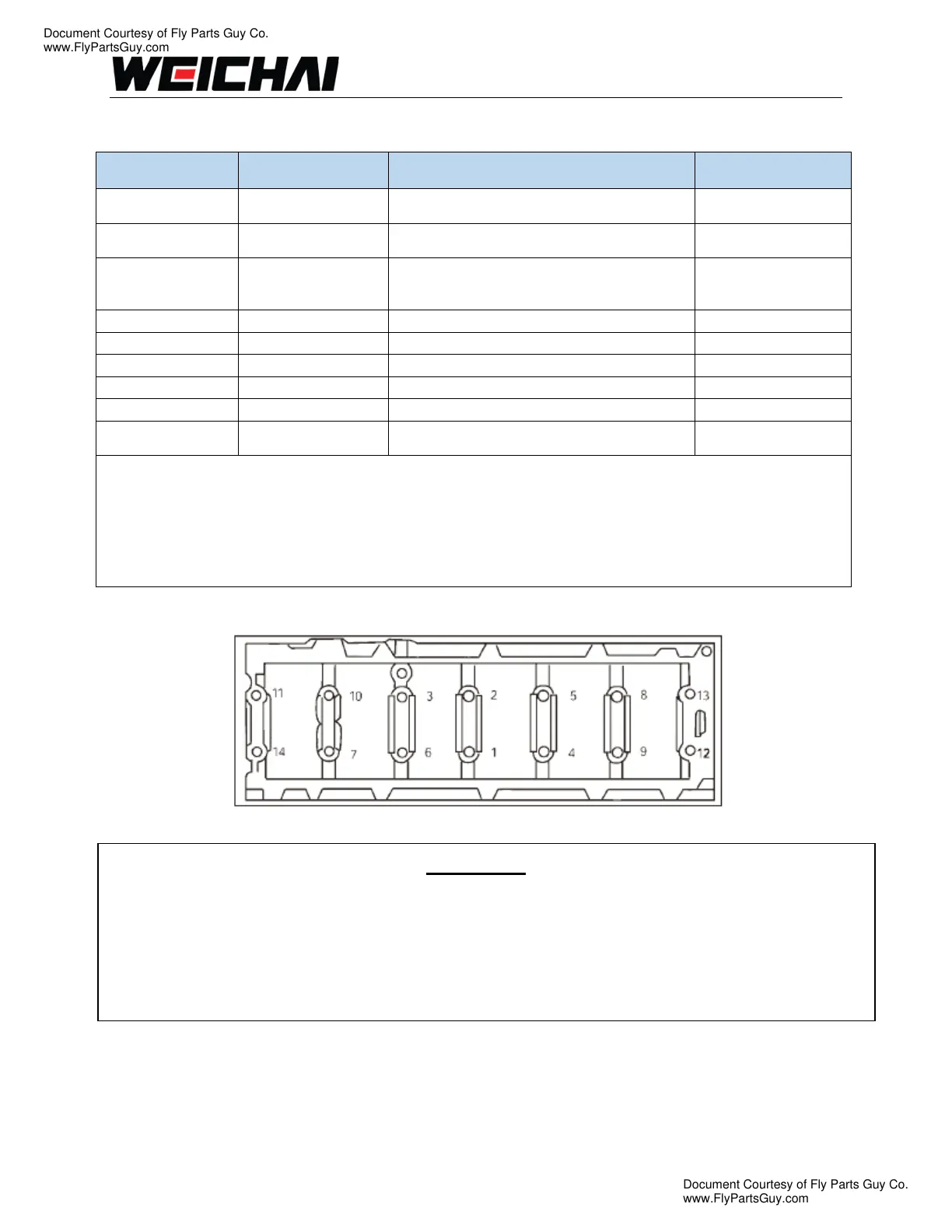

Engine Fastener Torque Specifications

Fastener’s Name Bolt Specification

Tightening torque (N·m) + further

turned angle (°)

Permissible times

of repeat used

Main bearing M18-10.9

The first time 80N·m, the second time 140N·m

the third time turn 90°, the last time turn 60°

2

Connecting rod M14x1.25

115N·m + (90±5°), (Reach 200 to 290N·m at

the same time)

0

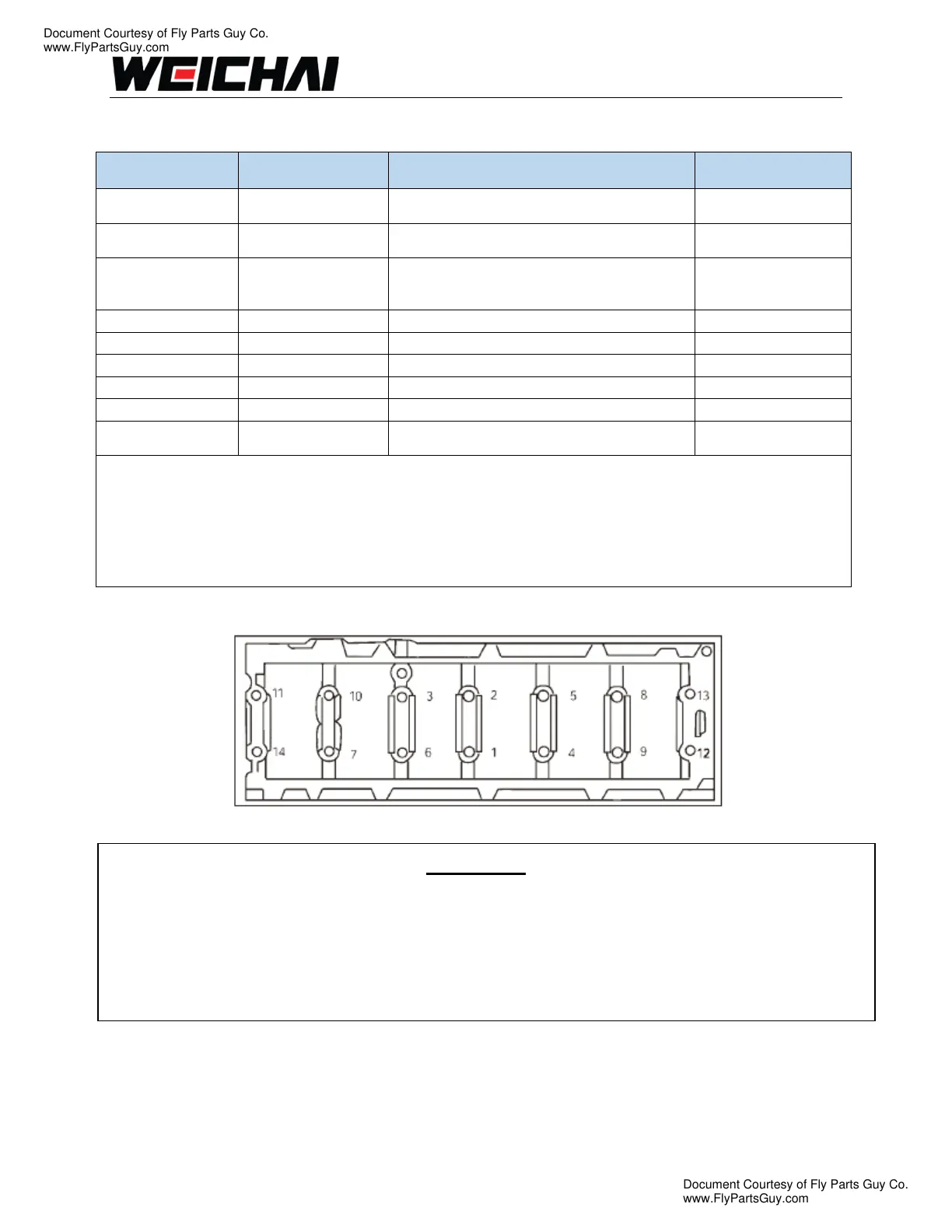

Cylinder head M14x2

60N·m +2x (120±5°), required sequence of

tightening (See illustration14)

3

Flywheel M16x1.5-10.9 105N·m +2x(90±5°) 2

Crankshaft pulley M12x1.5 45N.m +135º 2

Damper M10-10.9 60~70N·m -

Spark-plug M14x1.25 (25 to 28) N·m -

UEGO sensor M18x1.5 50N.m±5N·m -

Water temperature

sensor

M14x1.5 25N.m±5N·m -

① Values of superscript and subscript are permissible tolerance ranges

② The angle value is the further turned angle after reaching the specific torque

③ The number before the angle is the number of time to turn the angle

④ There are corresponding requirements on the strength classes of the bolts and nuts used at various positions of the

engine. It is forbidden to interchange the bolts and nuts of the same size but of different strength classes. It is

impermissible to exceed the allowed times of repeat use. Otherwise it will bring about severe outcome.

Table 5

Illustration 13

CAUTION

Failure to follow these instructions could cause damage or decrease the life of equipment.

Note in above Table 5 that connecting rod bolts cannot be re-used.

Document Courtesy of Fly Parts Guy Co.

www.FlyPartsGuy.com

Document Courtesy of Fly Parts Guy Co.

www.FlyPartsGuy.com

Loading...

Loading...