Operation and Maintenance Manual for WP2.1C/WP3.9C Series Marine Diesel

24

(4) Cooling water flow reduction due to lo

water pump efficiency.

Check clearance between water pump impeller and housing.

Replace impeller if necessary.

(5) Defective water pump impeller. Replace impeller.

(6) Cooling water circulation obstructed. Clean cooling system.

(7) Defective thermostat. Replace thermostat.

(8) Defective water thermometer. Replace thermometer.

(9) Insufficient lubrication. Inspect lubricating system and clean oil gallery.

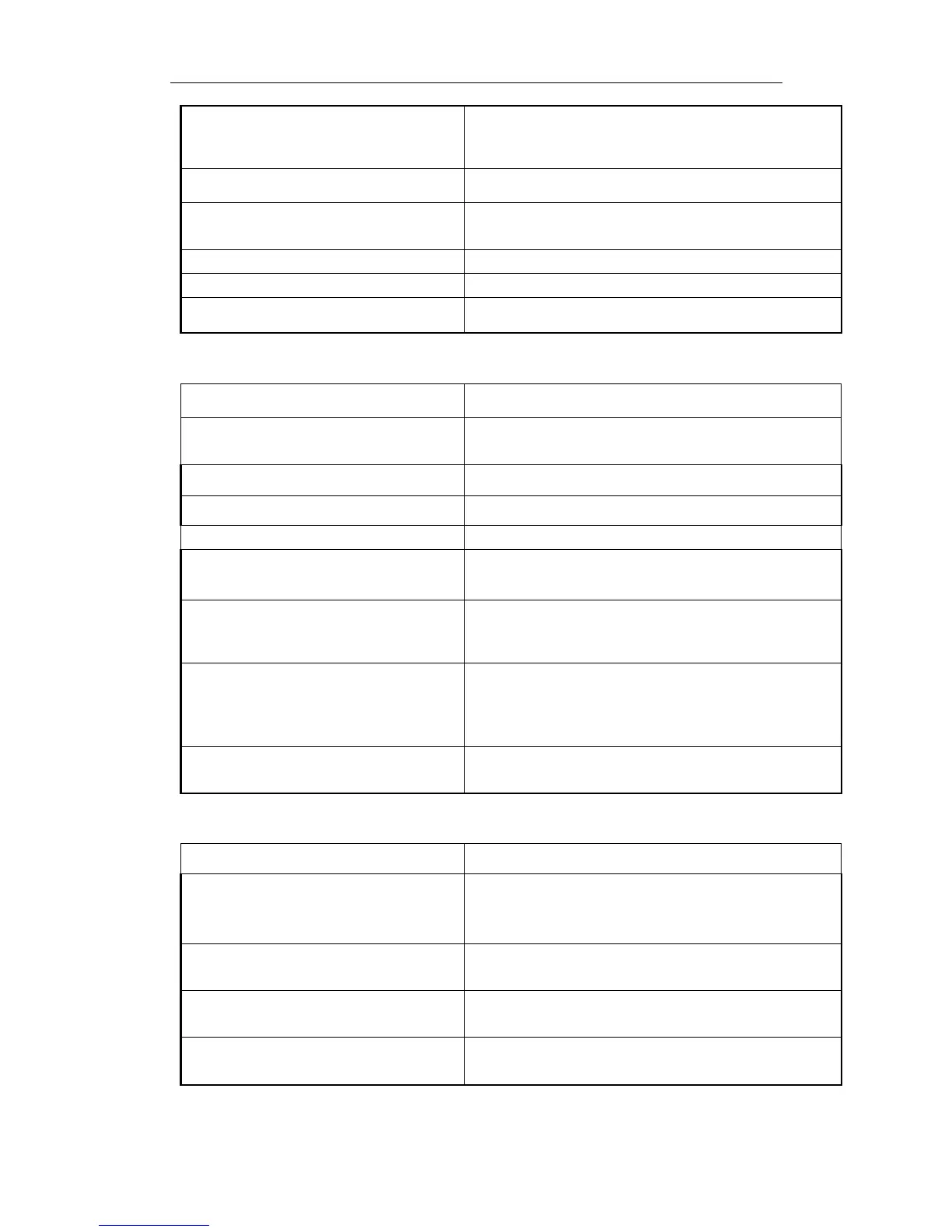

6.9 Low Lubricating Oil Pressure

Possible Causes Suggested Remedies

(1) Insufficient oil in oil sump.

Check oil level.

Refill to the specified level.

(2) Defective low oil pressure alarm. Replace alarm.

(3) Clogged oil gallery. Clean oil gallery and blow away dirt with compressed air.

(4) Clogged oil strainer. Dismount oil strainer. Clean it in kerosene.

(5) Clogged oil filter and defective by-pass

valve.

Replace oil filter cartridge. Readjust by-pass valve i

necessary.

(6) Excessive bearing clearances due to wea

of main bearing and crankpin bearing.

Repair or replace bearings.

(7) Engine overheated, causing high

temperature and low viscosity of lubricating

oil.

Reduce load to lower oil temperature or refill with suitable

oil.

(8) Too big clearance between oil pump

rotors and housing cover.

Replace rotors or housing cover of oil pump.

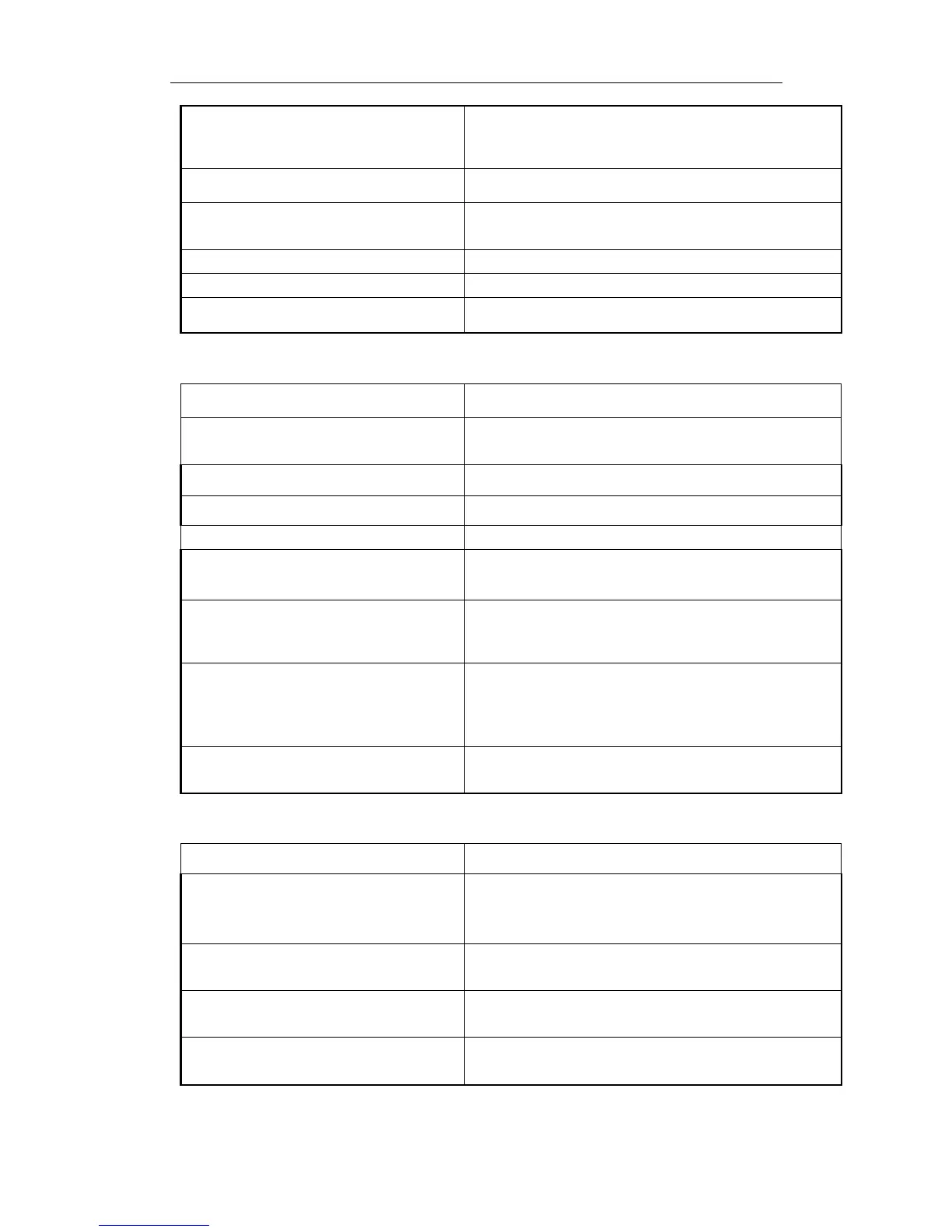

6.10 Excessive Oil Consumption

Possible Causes Suggested Remedies

(1) Worn piston ring or oil scraper ring

stuck in ring groove due to carbon deposits.

Wash oil scraper ring in kerosene or replace defective ring.

(2) Oil return holes plugged due to carbo

deposits.

Clean oil return holes in piston.

(3) Oil level too high. Oil into the

combustion chamber.

Check with dipstick and drain oil to correct level.

(4) Leakage in lubricating system. Tighten connectors and replace sealing washers and gaskets.

Loading...

Loading...