Primary/secondary piping to boiler

Using primary/secondary piping will provide the most effi cient

and reliable operation of the boiler and the heating system.

1. Use information beginning on page 47 to size pump for proper

fl ow through the ECO boiler.

2. Reference suggested piping layouts on pages 53 - 55 .

Some installations can be piped in numerous other ways

that will work equally as well as the suggestions here.

Verify the application will work:

For systems requiring a higher flow than that

recommended in Figure 47 − DO NOT use a

direct connect piping layout. Design system using

a primary/secondary piping layout using guidelines

starting on page 47 .

Systems zoning with circulators must use primary/

secondary piping layout using guidelines starting

on page 47 .

Check system fl ow rate

To determine whether direct connection will provide suitable fl ow

for the intended application, refer to Figure 41.

4. The minimum temperature drop across the heat exchanger

is 20°F. Using fl ow rates higher than the maximum listed in

Figure 41 is NOT RECOMMENDED.

5. Design zoning to ensure minimum fl ow rate is maintained

under any call for heat condition that could see full input

rate (High Fire).

Systems using a modulating pump may operate

below the minimum fl ow rates listed in Figure 47

only if the boiler is operating at a reduced fi ring rate

(low fi re) when doing so. A pump that modulates

based on the system Delta T (T) would provide such

operation assurance by varying fl ow with fi ring rate.

Use a primary/secondary piping layout if the total fl ow through

the ECO’s heat exchanger will be higher than the maximum listed

in Figure 47 .

Check system pipe design

Only systems with a single system pump zoned with zone valves

may use the direct connect system piping methods shown here.

Any system zoned with zone valves must include a

by-pass pressure regulator. Failure to comply may

reduce pump life.

Expansion tank location

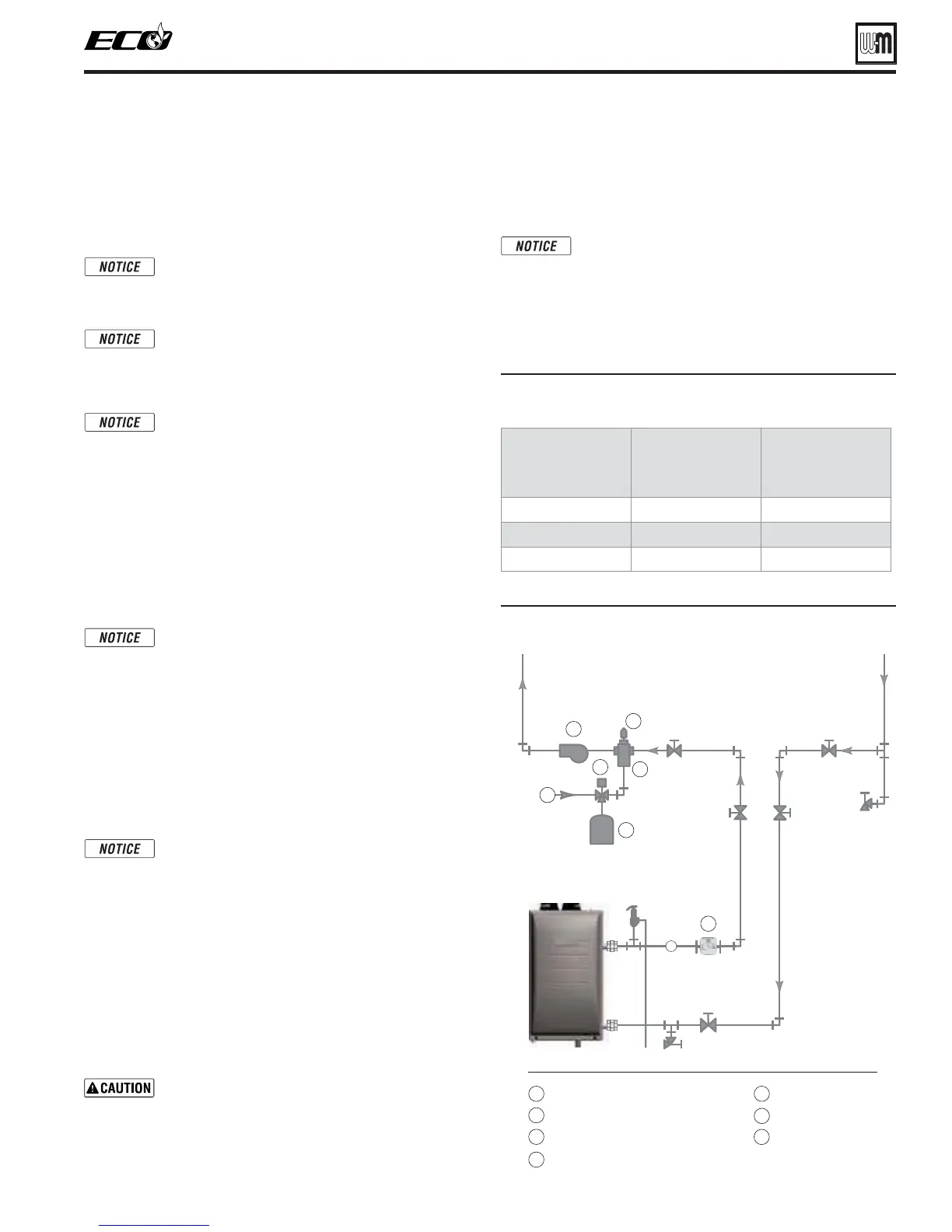

Figure 48 and Figure 50 show typical installation of the system

expansion tank. It is highly recommended that you locate the air

separator and expansion tank as shown in the suggested piping

drawings on page 47 and page 48 .

Ensure that the expansion tank size will handle boiler and

system water volume and temperature. See tank manufacturer’s

instructions and ratings for details. Additional tanks may be added

to the system if needed to handle the expansion. These tanks may

be installed by connecting to tees in the system piping.

Undersized expansion tanks cause system water to

be lost from the relief valve and makeup water to be

added through the fi ll valve. Eventual boiler failure

can result due to excessive make-up water addition.

Always locate the cold-water fi ll connection at the

expansion tank. Never locate this elsewhere.

Diaphragm- or bladder-type tank:

Refer to Figure 48 for suggested piping when using a diaphragm-

or bladder-type expansion tank.

Install an automatic air vent on top of the air separator, per

separator manufacturer’s instructions.

Diaphragm- or bladder-type expansion tank—

Control fill pressure with the tank air charge

pressure. Always check pressure and charge tank

with tank removed from system to be sure reading

is accurate. Boiler relief valve is set for 30 PSIG.

Operating pressure of system, after temperature

expansion above cold fi ll pressure, should not exceed

24 PSIG to avoid weeping of relief valve.

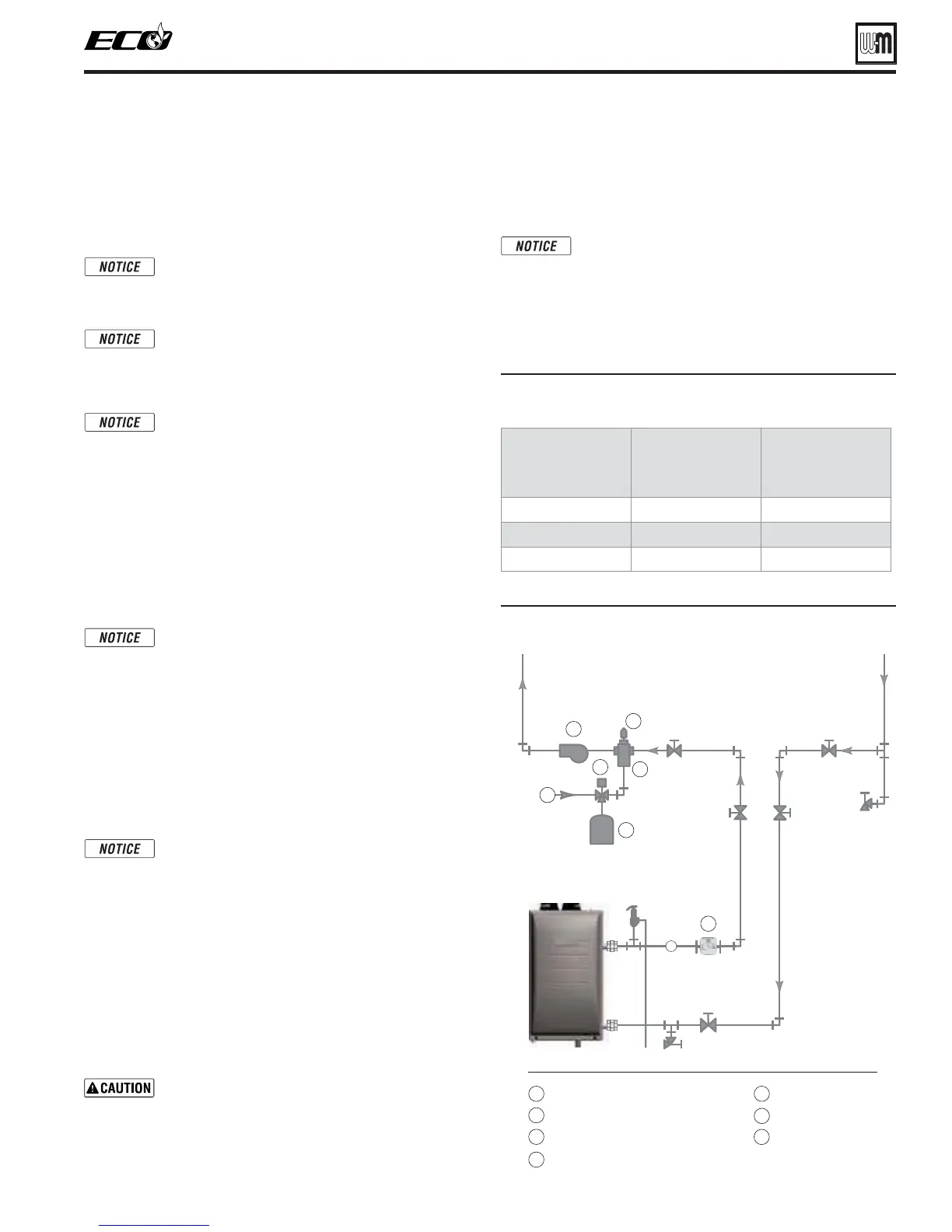

Figure 47 Maximum and minimum fl ow rates through

boiler heat exchanger

ECO

Model

MAXIMUM

fl ow rate

through

boiler

MINIMUM

fl ow rate

through

boiler

70

6.5 GPM 3.0 GPM

110

10.0 GPM 5.0 GPM

155

14.5 GPM 7.0 GPM

Figure 48 Piping to diaphragm- (or bladder-) type

expansion tank

Direct Connect System Piping

Part number 550-142-190/1218

43

SERIES 2 GAS-FIRED WATER BOILER — Boiler Manual

4ZTUFN

SFUVSO

4ZTUFN

TVQQMZ

'JMMWBMWFUZQJDBM

.BLFVQXBUFSTVQQMZ

"JSTFQBSBUPS

4ZTUFNDJSDVMBUPS

"VUPNBUJDBJSWFOU

%JBQISBHNUZQFFYQBOTJPOUBOL

&$0

-PX8BUFS$VU0GG

*GVTFE

#PJMFS

PVUMFU

#PJMFS

SFUVSO

Loading...

Loading...