3

V. Description of Operation:

VI. Maintenance:

Any type of liquid may be unloaded through the valve. The

valve will tolerate clean liquids better than others. And

lighter liquids will flow at greater rates than heavier liquids.

Particulates, abrasives and contaminants will not preclude

the valve from opening at the appropriate set pressure.

However, abrasive materials will cause some wear between

the wear sleeve, nozzle, and main seal. While these

components are made with wear resistant surfaces, their life

will be reduced as the abrasives increase in the fluid.

The effective accuracy of set pressure versus opening

pressure is limited by gauge accuracy (1-3%) and regulator

accuracy (1-2%). Weir SPM tests show the accuracy of the

Unloading Valve does not vary more than ± 2.5%.

NOTE:

Under most conditions, the valve will reset completely when

the fluid source is removed and the liquid pressure at the

valve is reduced close to zero. This is generally true if the

initial nitrogen pressure is set above 120 psi.

However, when the initial nitrogen pressure is below 120 psi

(i.e. 3500 psi liquid pressure) it may be necessary to use the

optional override valve to force the relief valve to reset.

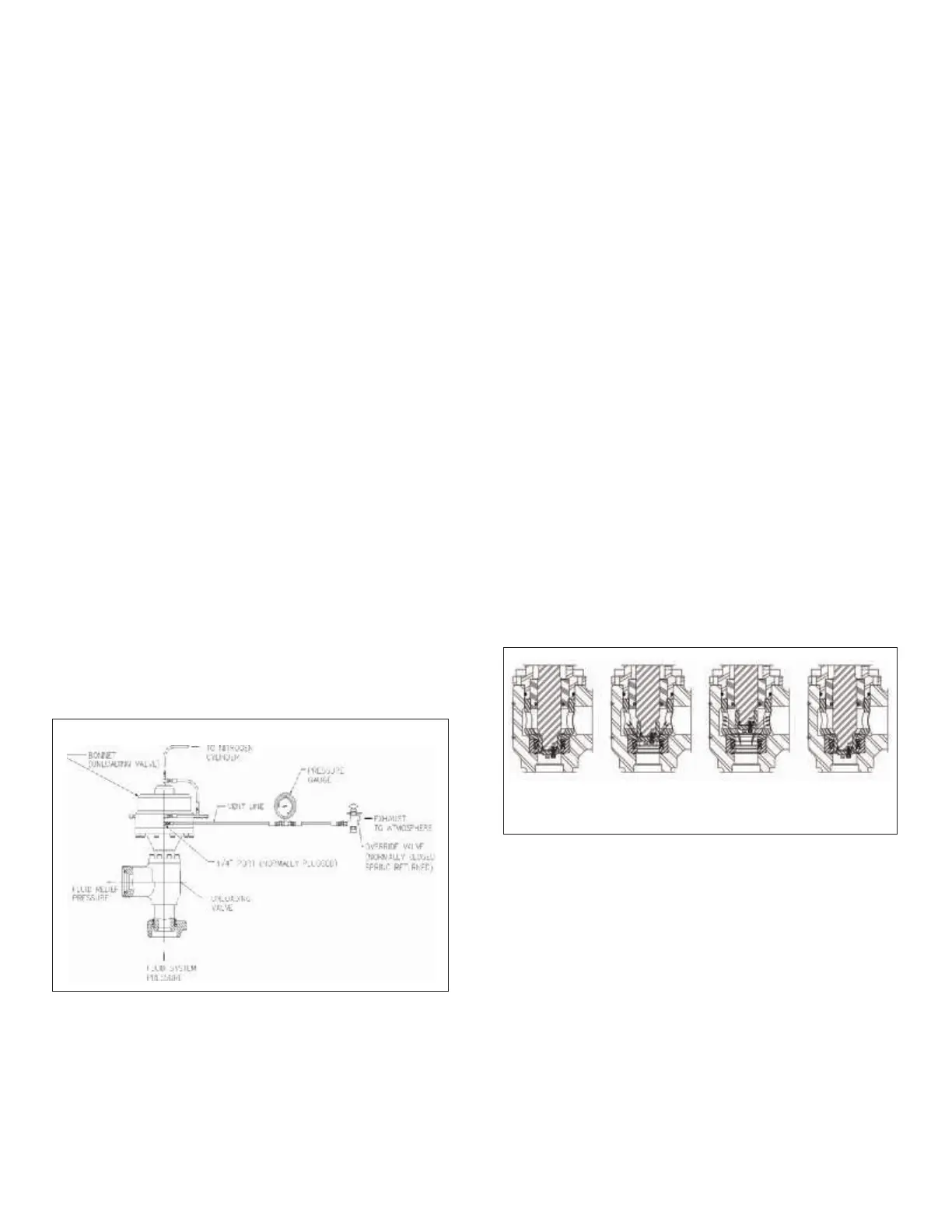

Figure 2 illustrates the circuit required to employ the

override valve. The vent line connects to the valve through

the ¼” port, replacing the pipe plug which is normally

installed. The override is a normally closed, spring returned

valve. Once the Unloading Valve has sequenced and is ready

to reset, the override valve must be opened and held open

for approximately 5 seconds to relieve gas pressure in the

bonnet.

Monitor the pressure gauge until it reduces to zero. At this

point the Unloading Valve is reset and the override valve

should be released.

FIG. 2

CAUTION:

It is important for the user to consider the

consequences of a valve that does not fully reseat

after it has relieved. In the event that this might

present a danger to personnel or equipment, SPM

highly recommends that an isolator valve be placed

between the pressure line and the Relief Valve.

separate series of H2S service unloading valve.

CAUTION:

Weir SPM’s 3” standard service Emergency

Unloading Valve is not intended for use in the sour

gas environment. DO NOT USE FOR H2S SERVICE.

Weir SPM does offer a separate series of H2S service

unloading valve. Contact your Weir SPM

representative for advice about sour gas service

applications.

The unloading valve operation is a simple balance between

the nitrogen (or suitable gas) acting on the piston and the

inlet liquid pressure acting on the rod and wear sleeve. The

equation is Pressure times Area equals Force (PxA=F). The

ratio of areas is approximately: 25 : 1

Consequently, a theoretical nitrogen pressure of 100 psi can

counter an inlet line pressure of 2500 psi for the unloading

valve. Variations in actual performance are due to internal

friction and will be discussed in (Section VIII).

With the device installed, as shown in (Fig. 1), any time the

pressure exceeds the set pressure at the Unloading Valve,

the fluid will pass through the valve and out the discharge.

As the rod and wear sleeve rise due to the liquid pressure

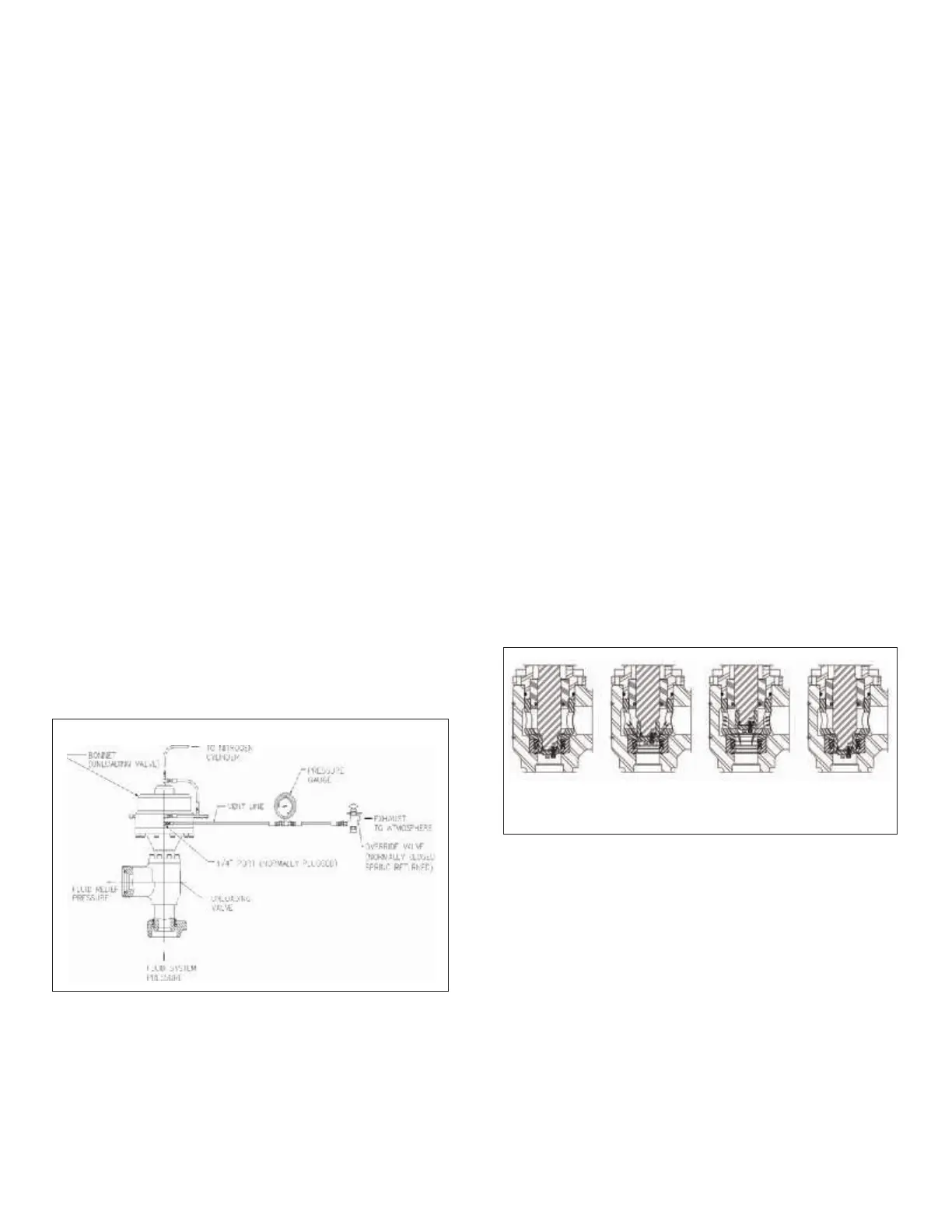

the valve goes through a transition zone (Fig. 3). During

this process the effective force from the nitrogen (or gas)

side is reduced to approximately 16% of its initial set

pressure, allowing the valve to open quickly and almost

completely.

a.) Fluid pressure below set pressure-rod and wear sleeve seated.

b.) Fluid pressure slightly above set pressure-rod and wear sleeve

off main seal.

c.) Fluid pressure substantially above set pressure-rod and wear

sleeve off main seal.

d.) Fluid pressure below set pressure-rod and wear sleeve reseated.

FIG. 3

a) b) c) d)

General:

The Weir SPM 3" Emergency Unloading Valve is a well

designed, dependable component that should provide long

term reliable performance for the user. Like any device,

however, it requires routine inspection and servicing to

guarantee that it is fully functional.

The valve is intended to be used as an emergency pressure

relief device only, and should not be subjected to

Loading...

Loading...