5

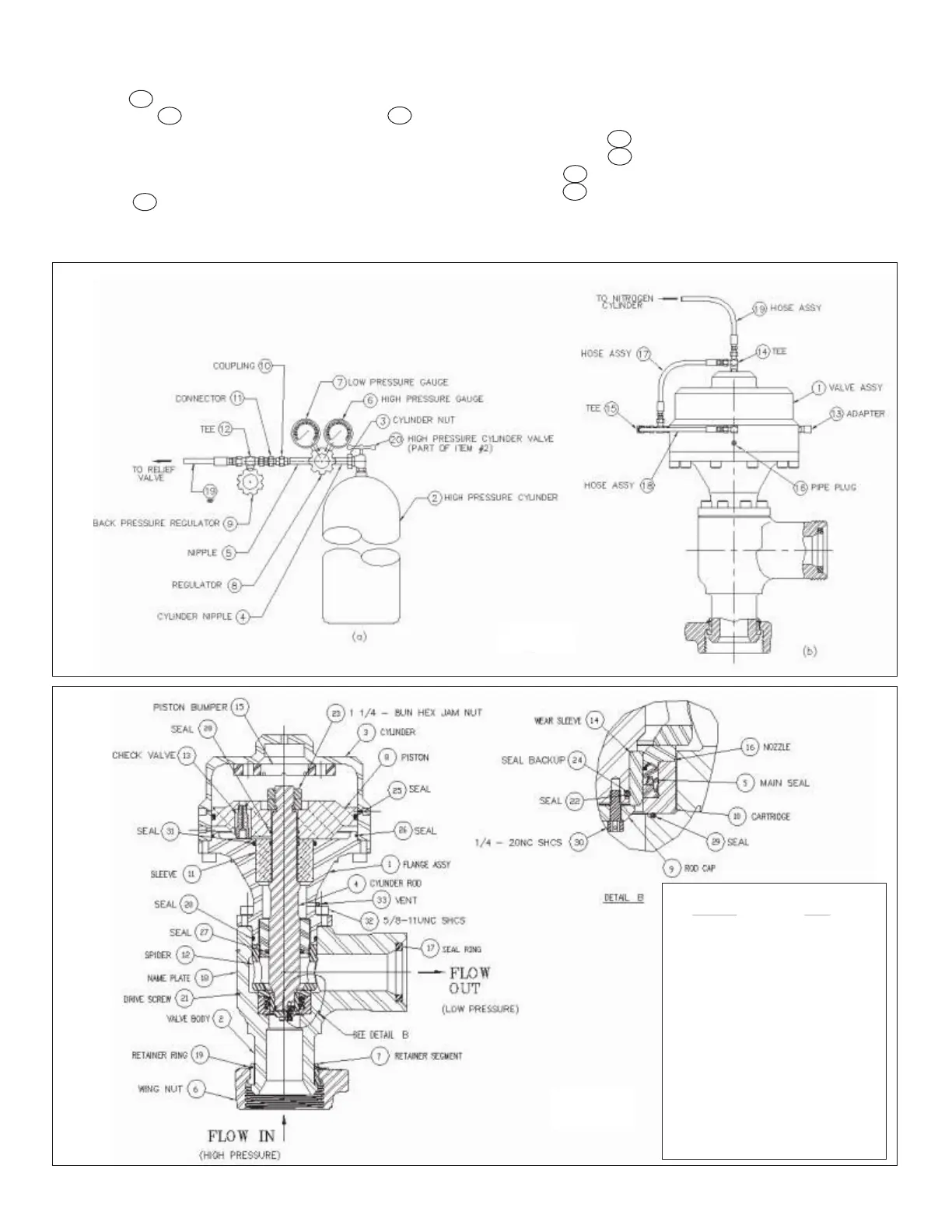

5.) Flange 1 :

Inspect the seal 31 pocket at the top and the seal 27

pocket in the nylon sleeve at the bottom. The sleeve and

seal pockets should be in good condition. If not the flange

should be replaced.

6.) Spider 12 :

Visually inspect the fluid discharge areas for erosion and

corrosion. Some wear in these areas is expected. Any

damage in these areas that extends deeper than .06"

renders the parts unusable and they should be replaced.

7.) Cartridge 10 :

Inspect the seal 29 surface where the cartridge fits against

the body 2 . Inspect the seal surface where the main seal

assembly 5 fits. If these surfaces have deteriorated, the

cartridge should be replaced.

Ref. No. Part No.

Complete Internal Parts Kit 4L23547

5 3A23356

10 3P23295

11 3P23297

12 3P23298

14 3P23308

16 3P23330

17 4P10258

20 P16637

22 P20006

24 P23302

25 P23303

26 P23304

27 P23333

28 P23334

29 P23335

31 P100875

33 P24707

Seal Kit 4L23549

5 3A23356

17 4P10258

20 P16637

22 P20005

24 P23302

25 P23303

26 P23304

27 P23333

28 P23334

29 P23335

31 P100875

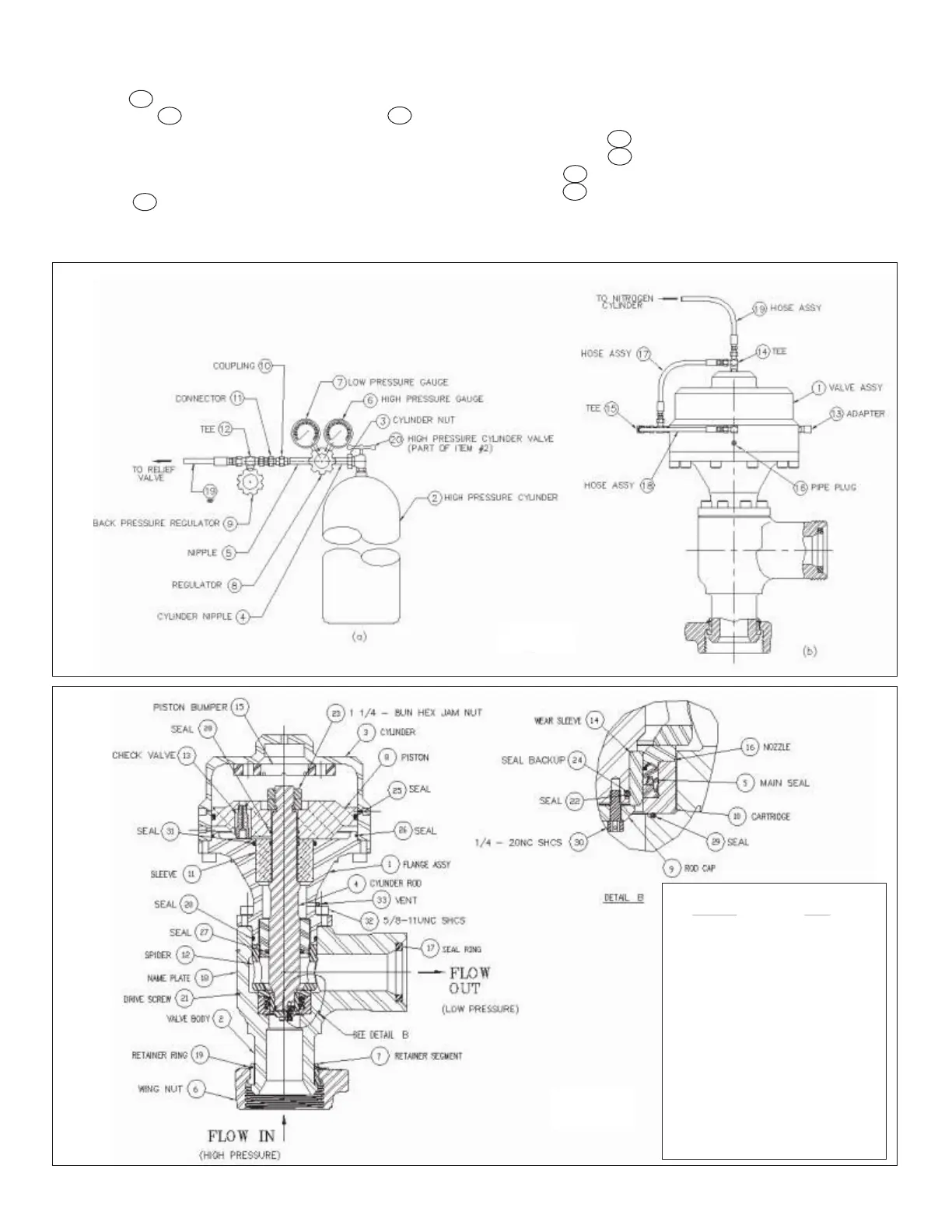

FIG. 4

FIG. 5

Ref. No./FIG 5 Part No.

Complete Internal Parts Kit 4L23547

5 3A23356

10 3P23295

11 3P23297

12 3P23298

14 3P23308

16 3P23330

17 4P10258

20 P16637

22 P20006

24 P23302

25 P23303

26 P23304

27 P23333

28 P23334

29 P23335

31 P100875

33 P24707

Seal Kit 4L23549

5 3A23356

1 4P10258

20 P16637

22 P20005

24 P23302

25 P23303

26 P23304

27 P23333

28 P23334

29 P23335

31 P100875

WEIR SPM REPAIR KITS

VII. Service: (Con’t)

Loading...

Loading...