20 Part Number 000016034 Rev 00 07/19

Installation Instructions Section 2

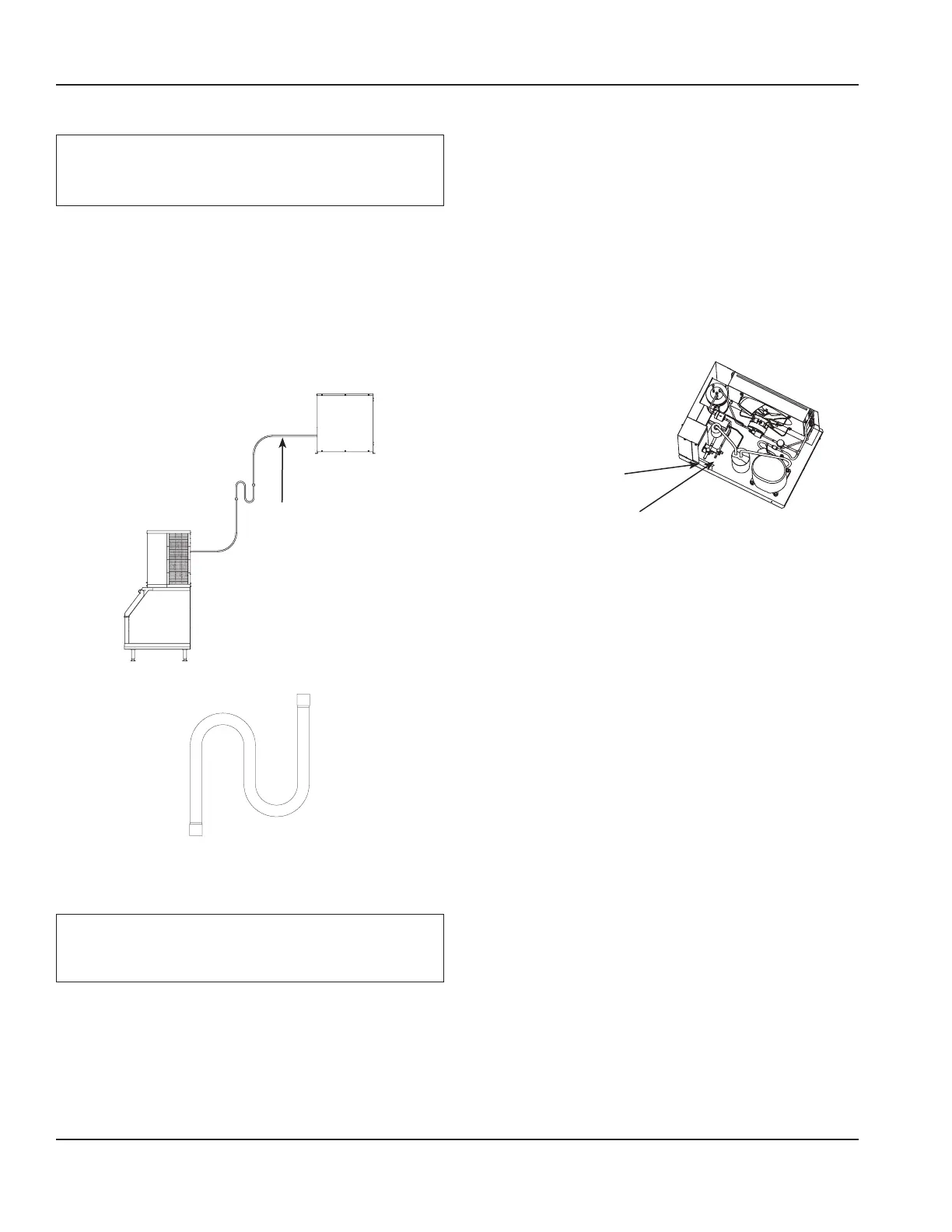

C. SUCTION LINE OIL TRAPS

,

Caution

Do not form unwanted traps in refrigeration lines. Never

coil excess refrigeration tubing.

0 to 6.1 m Rise: No oil trap is required when the condensing

unit is located 6.1 m or less above the ice machine head

section.

6.4 to 10.7 m Rise: The suction line requires an additional

Oil Trap (“S” type) to be installed. Install the trap as close as

possible to midpoint between the ice machine head section

and remote condensing unit. S-Trap Kits are available from

Manitowoc.

6.4 m OR

MORE RISE

ADDITIONAL

TRAP KIT

REQUIRED

Step 3 Lengthening or Reducing Line Set Lengths

,

Caution

Do not form unwanted traps in refrigeration lines. Never

coil excess refrigeration tubing.

When the line set requires shortening or lengthening, do

so before connecting the line set to the ice machine head

section or the remote condensing unit.

Step 4 Connecting the line set

To prevent oxidation of the copper, purge line set and

condensing unit with dry nitrogen while brazing.

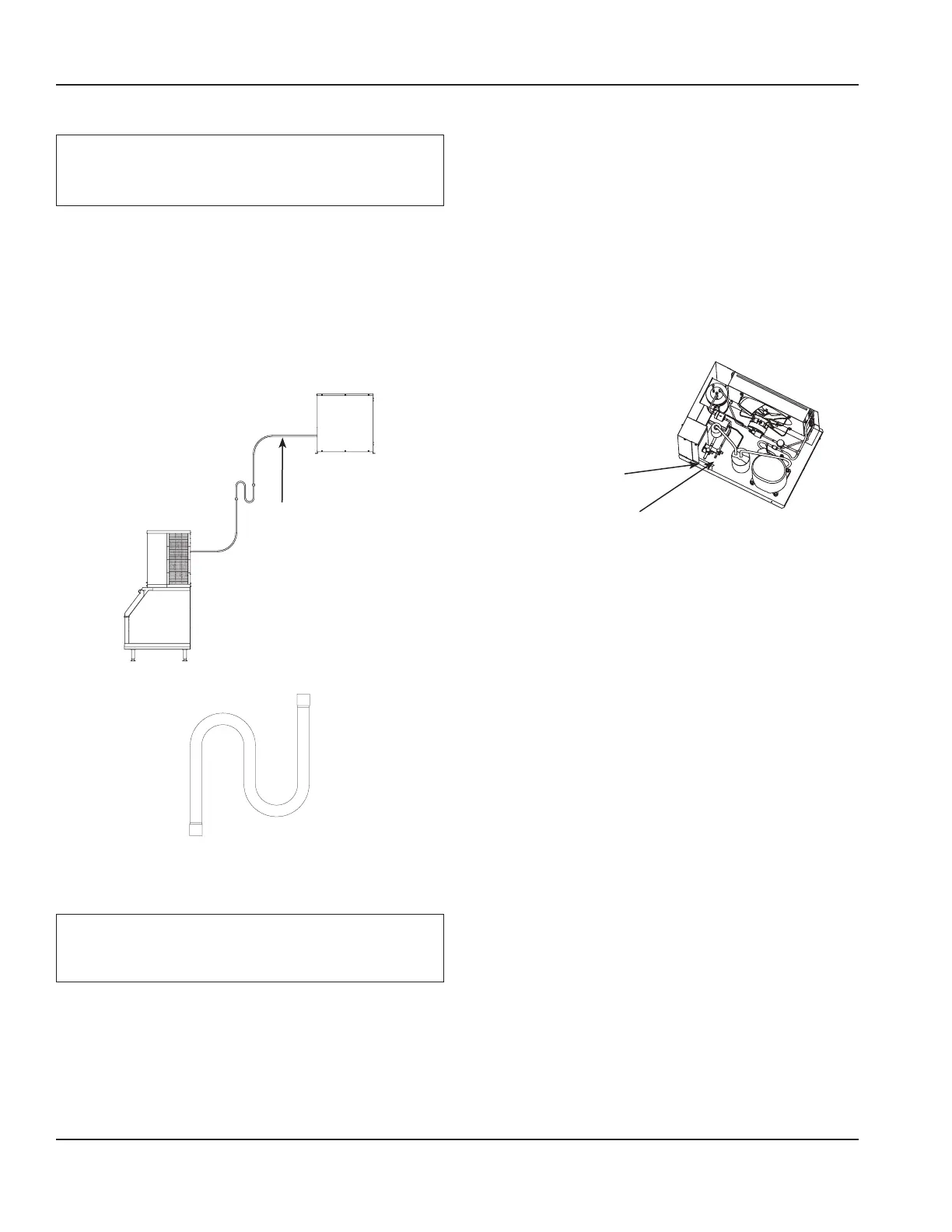

A. Connect the Line Set to the Remote Condensing Unit

The condensing unit is not shipped with a refrigerant charge.

Do not expose the refrigeration oil or system to atmosphere

for more than 15 minutes. The line set shut-off valves can

remain closed or be opened during brazing. Protected the

valves from heat during the brazing process. Wrap the valves

in a wet rag or other type of heat sink prior to brazing. Cool

braze joint with water immediately after brazing to prevent

heat migration to the valve.

SUCTION LINE

LIQUID LINE

MINIMIZE THE TIME THE

REFRIGERATION SYSTEM IS

EXPOSED TO THE ATMOSPHERE

(15 MINUTES MAXIMUM)

B. Connect the Line Set to the Ice Machine Head Section

• Cut the suction and liquid tubing with a tubing cutter,

leaving enough tubing to easily braze.

• Connect the line set.

• Cool braze joint with water immediately after brazing to

prevent heat migration.

Loading...

Loading...