3 / AUTO-DARKENING FILTER (ADF) CONTROLS & FEATURES – Cont’d

c. SENSITIVITY CONTROL

This adjusts the sensitivity of the arc sensors to best suit the welding task & sur-

rounding environment. Low sensitivity helps prevent the ADF reacting other nearby

light sources. High sensitivity may be required if welding on low current &/or when

TIG welding. Low to mid sensitivity is recommended for most welding applications.

d. SHADE ADJUSTMENT

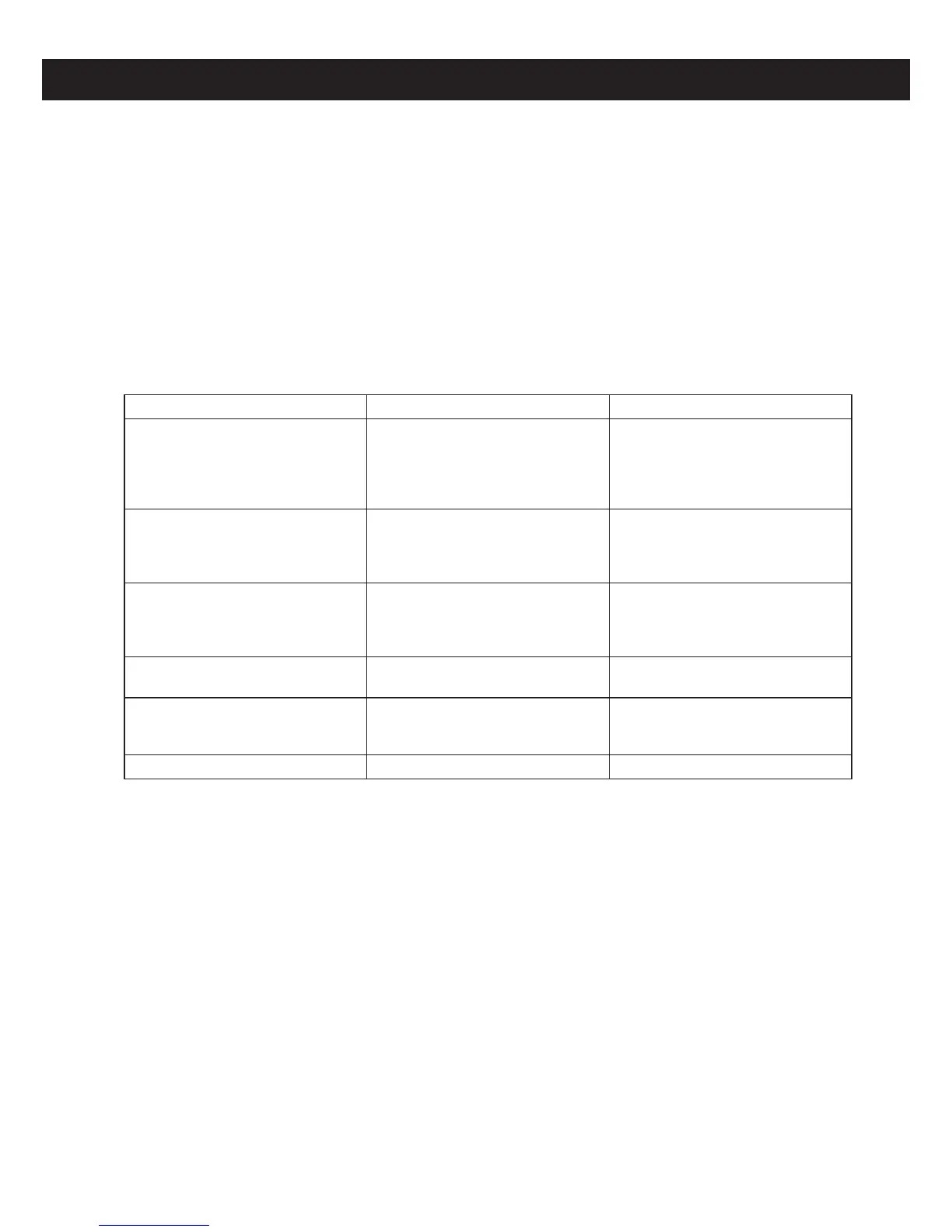

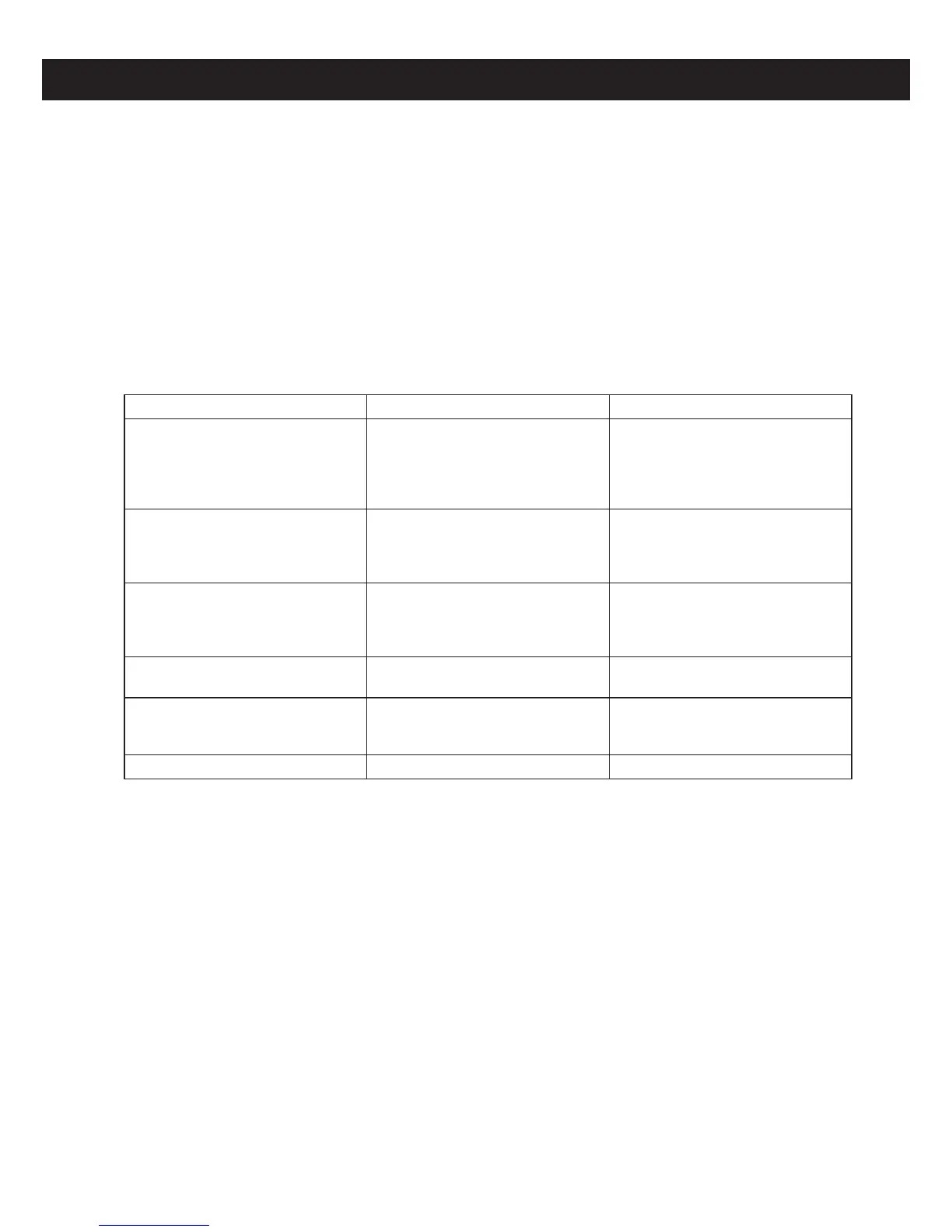

The following chart shows recommended shade levels for dierent welding applica-

tions.

Welding Application Arc Current in Amps Protective Shade No.

Stick Electrode (MMA)

Less than 40

40-80

80-175

175-300

300-500

9

10

11

12

13

MIG

Less than 100

100-175

175-300

300-500

10

11

12

13

TIG

Less than 50

50-100

100-200

200-400

8-10

11

12

13

Air Carbon Arc Gouging

Less than 500

500-700

12

13

Plasma Arc Cutting

Less than 80

80-150

150-350

8-9

10-11

12-13

Gas Welding & Cutting - 5-6

e. DELAY ADJUSTMENT

This adjust the time the ADF takes to switch from dark back to light when welding

stops.

Short delay time is best for tack welding and short welds. A longer delay may be

required if welding heavier materials, where the weld pool emits bright light for a

brief period.

f. WELD/GRIND SWITCH

(Excludes Promax 180)

Switching to ‘Grind’ mode will ‘lock’ the ADF into the light shade mode so that it will

not activate whilst the operator is grinding.

WARNING: Never use the helmet for welding whilst the ADF is switched to ‘Grind’.

WARNING: Always wear safety spectacles or goggles under the helmet when

grinding.

Loading...

Loading...