2.5 Purging the Unit

Welker recommends the Welker PNPPlug & Purge Panel for use with this unit.

To prevent cross-contamination between samples, Welker recommends that the inLoop™ ACE be evacuated, or purged,

following each sample batch to inject all sampled product remaining in the unit into the sample container.

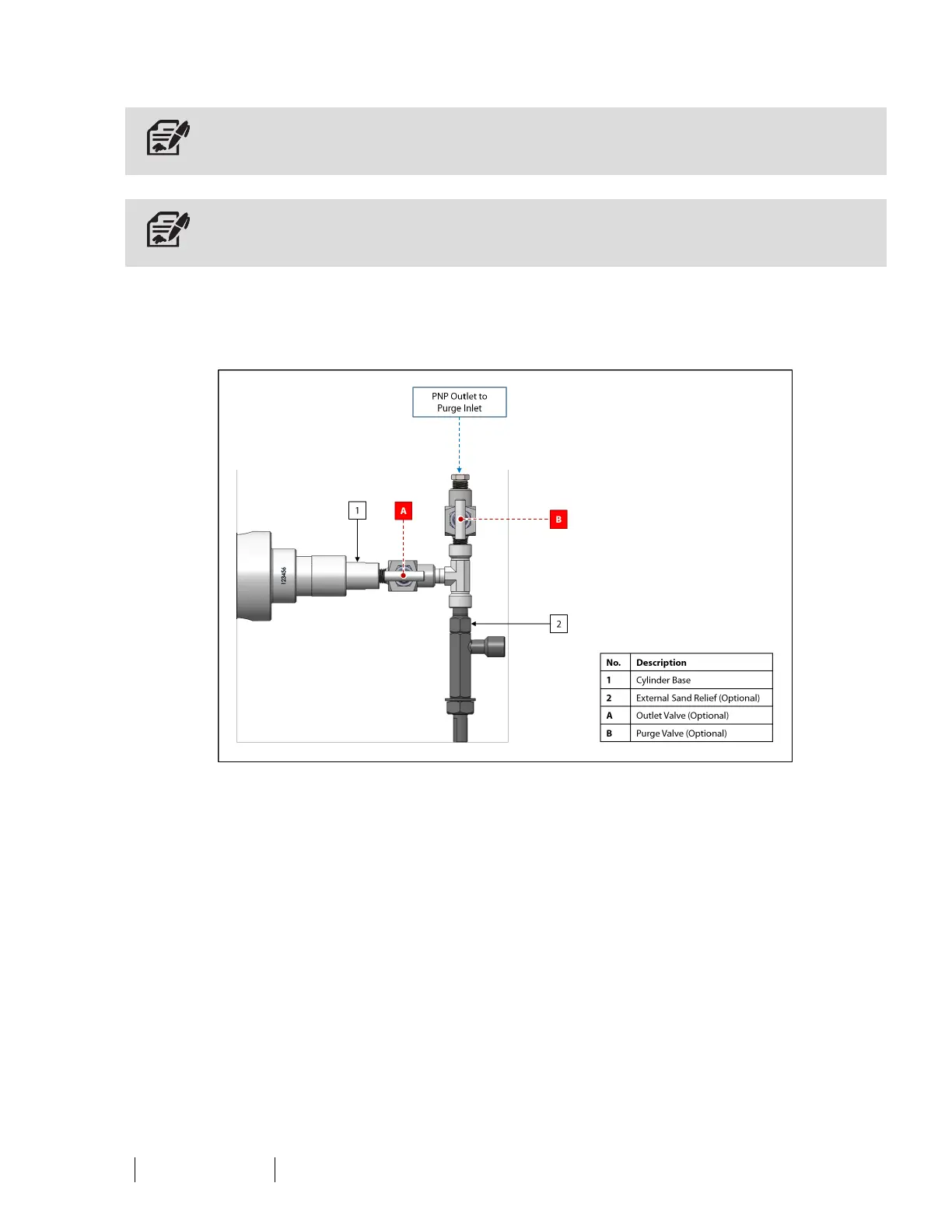

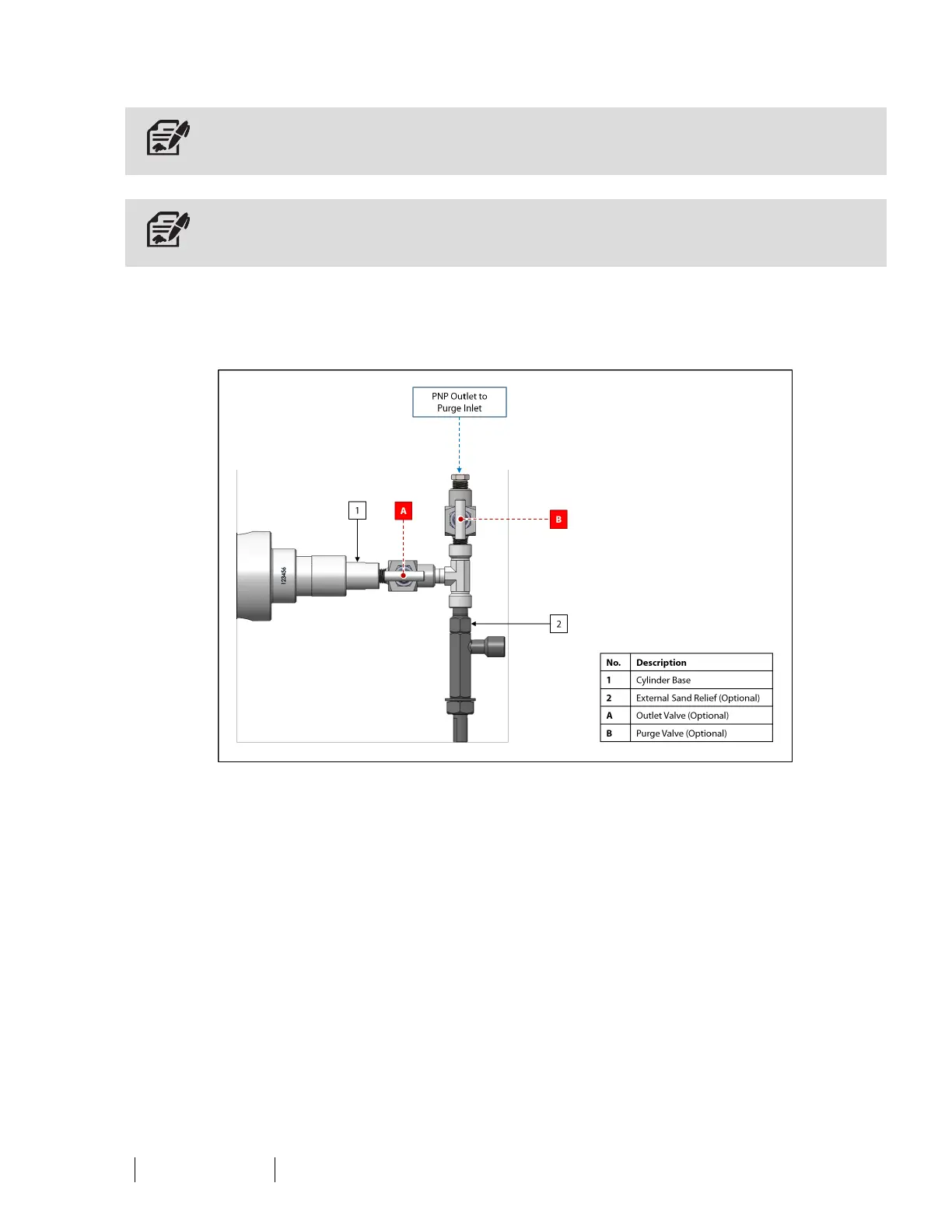

1. If the inLoop™ ACE is not equipped with the optional purge, Welker recommends installing a customer-supplied tee

fitting with valve(s) to the sample outlet so that the inLoop™ ACE can be purged (Figure 10).

Figure 10: Recommended Arrangement for Purge

2.

Ensure that the Welker PNPPlug &Purge Panel has been installed correctly. Refer to the Installation, Operation, and

Maintenance (IOM) Manual for the PNP for installation instructions.

3.

Using ¼" tubing, connect from the purge outlet on the PNP to purge valve B (Figure 10).

4.

Ensure that an appropriate inert gas supply is connected to the PNP. As necessary, refer to the Installation, Operation,

and Maintenance (IOM) Manual for the PNP for instructions.

5.

If applicable, ensure that the PNPpressure transmitter has been configured. As necessary, refer to the Installation,

Operation, and Maintenance (IOM) Manual for the PNP for instructions.

6.

Set the purge pressure to a pressure appropriate for the sampling system. Refer to the Installation, Operation, and

Maintenance (IOM) Manual for the PNP for instructions.

7.

Open purge valve B (Figure 10).

8.

Follow the instructions in the Installation, Operation, and Maintenance (IOM) Manual for the PNPto complete the purge.

18

IOM-224 MODEL: INLOOP™ ACE REV: A 13839 West Bellfort Street, Sugar Land, TX 77498 welker.com Service Department 281.491.2331

Loading...

Loading...