WARNING! Before any assembly of the chuck to the

drill press spindle, clean all mating surfaces with a non-

petroleum based product; such as acetone or lacquer

thinner. Any oil or grease used in the packing of these

parts must be removed; otherwise the chuck may come

loose during operation.

12

1

ASSEMBLY & ADJUSTMENTS

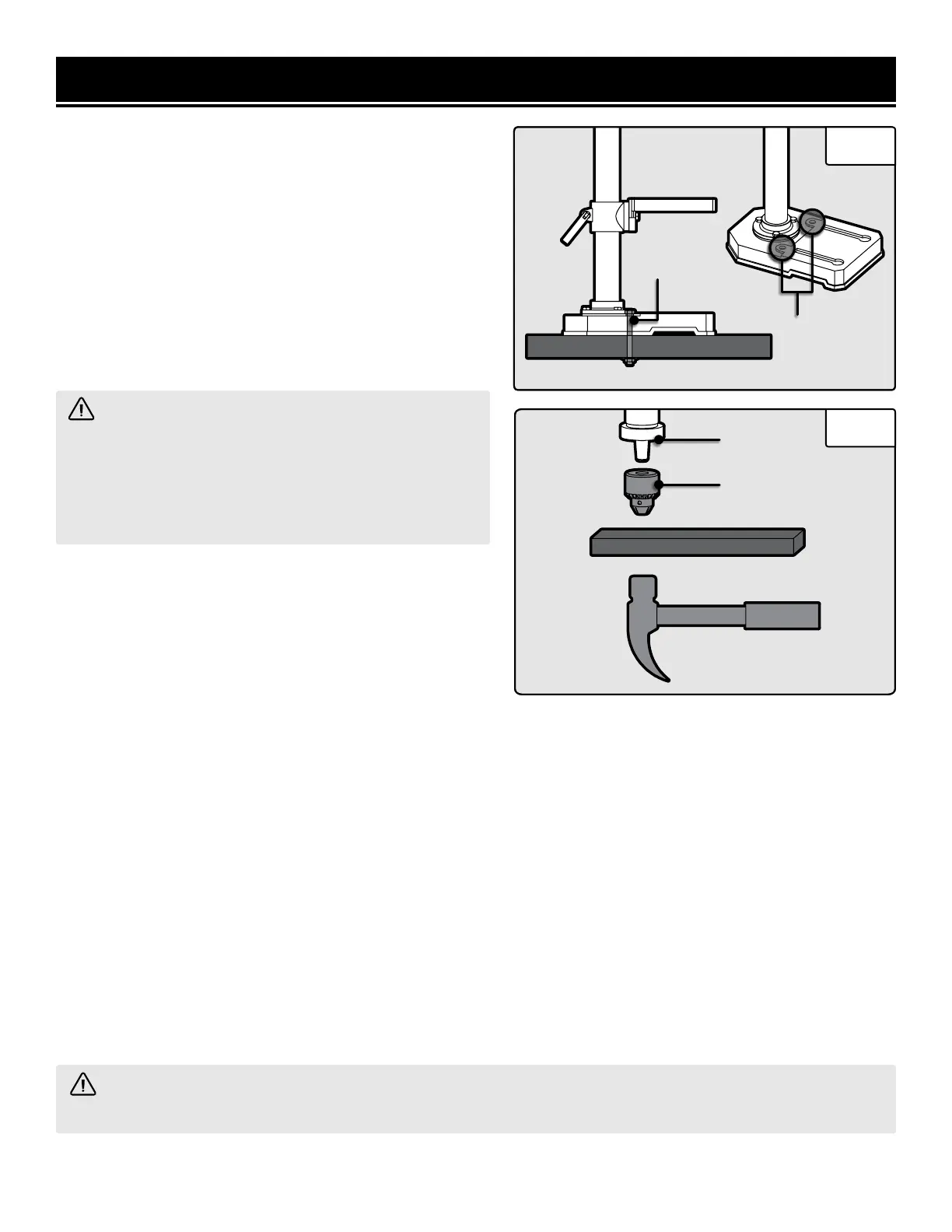

MOUNTING THE DRILL PRESS

The drill press must be securely fastened through the

mounting holes (Fig. 5 - 1) to a stand or workbench with

heavy-duty fasteners (Fig. 5 - 2) (fasteners and mounting

hardware not included). This will prevent the drill press

from tipping over, sliding, or walking during operation.

IMPORTANT: If the stand or workbench has a tendency to

move during operation, fasten the workbench securely to

the floor.

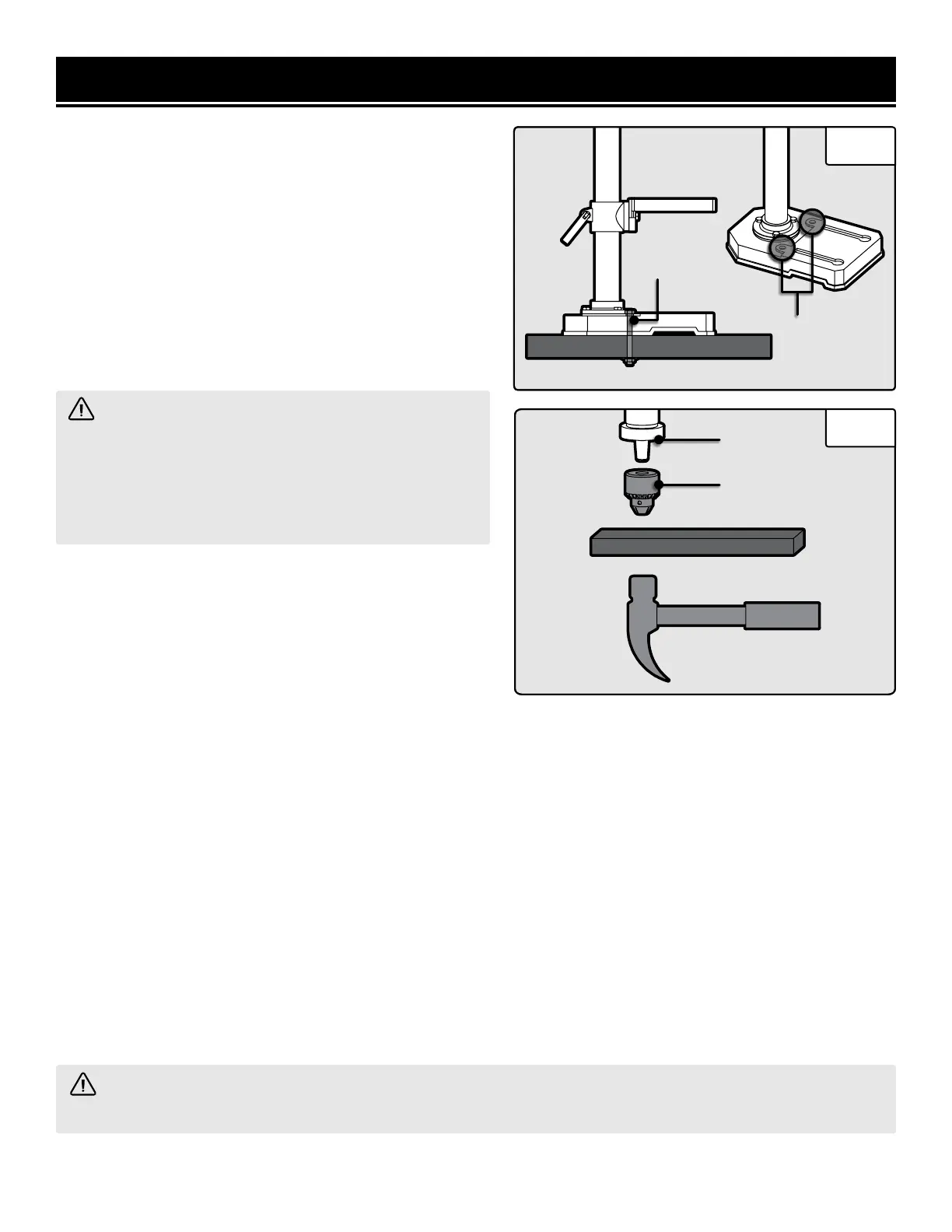

INSTALLING THE CHUCK

1. Unplug your drill press before you begin installing the

chuck. Lower the drill press table and place a cloth on it to

protect the chuck if it is dropped.

2. Wipe the chuck and spindle with a clean rag. Do not use

solvents yet, these will be used when you are ready to set

it into place.

2

Fig. 6

3. Completely remove any burrs found on the inner mating surface of the chuck with a diamond coated tool or a

fine file. Use a grade 000 steel wool pad to lightly go over the chuck and spindle. This removes oxidation and dirt

that you cannot see.

NOTE: Do steps 1-3 even if your chuck is new. New chucks can still have burrs, oxidation, and dirt.

4. Use lacquer thinner or acetone on a lint free rag to clean the chuck. Do not touch these surfaces with your

hands

after cleaning. Rubbing alcohol does not work well, as it contains oil. Let the chuck dry before continuing.

5. Retract the jaws of the chuck all the way into the body. Slide the chuck’s socket onto the spindle.

6. Using hand force, firmly push the chuck (Fig. 6 - 1) up onto the spindle (Fig. 6 - 2). Using a rubber mal-

let or dead blow hammer, tap the chuck upwards once to lock the tapers together. You can also use a piece

of wood between the chuck and a standard hammer (Fig. 6). Test the fit by gently pulling downward on the

chuck. If the chuck pulls off, go back to step one and try again, making sure to thoroughly clean the mating

surfaces. Your chuck is now set into your drill press and should stay in place until you need to remove it.

Fig. 5

1

CAUTION! To avoid damaging the chuck, make sure the jaws are completely recessed into the chuck. Do not

use a metal hammer to drive the chuck into the spindle.

2

Loading...

Loading...