ASSEMBLY & ADJUSTMENTS

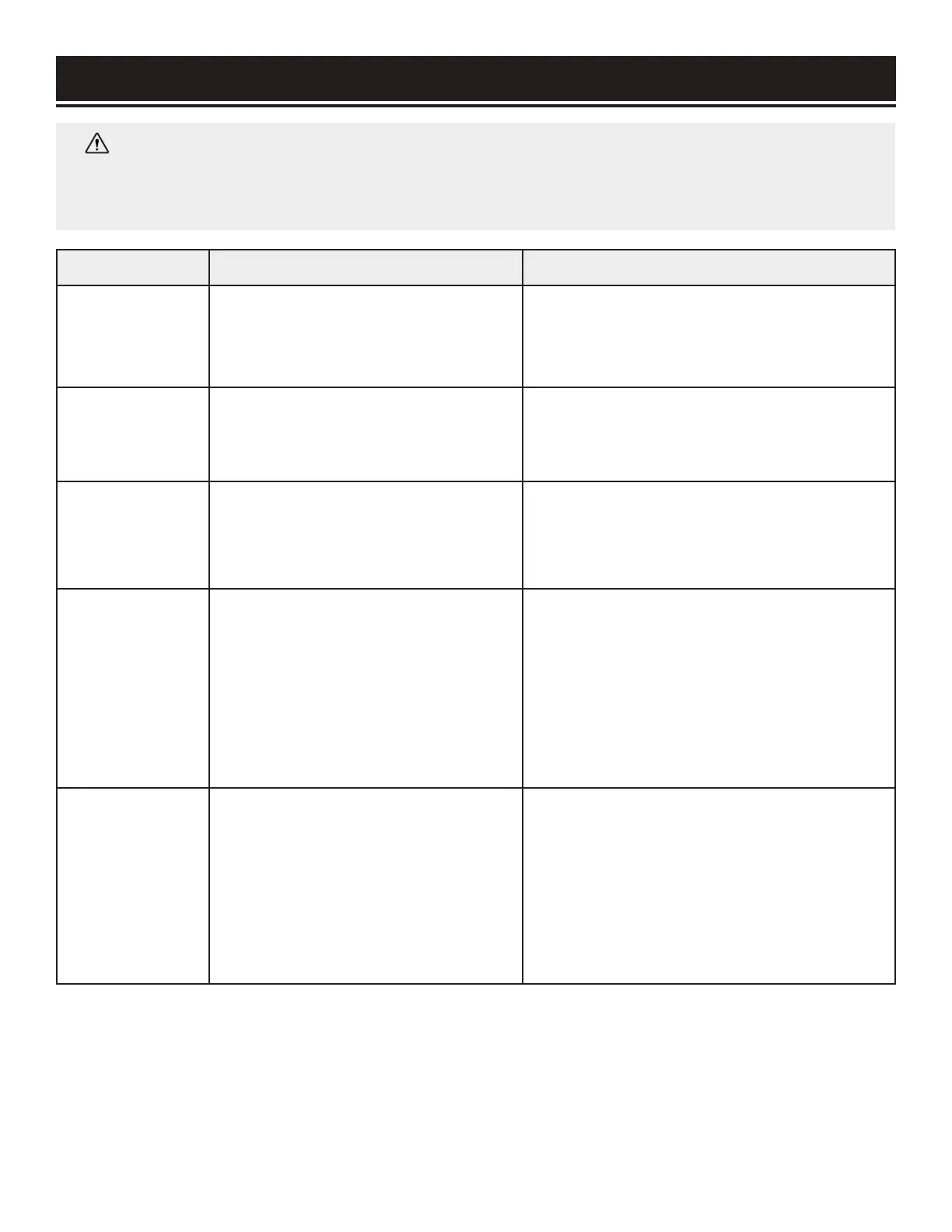

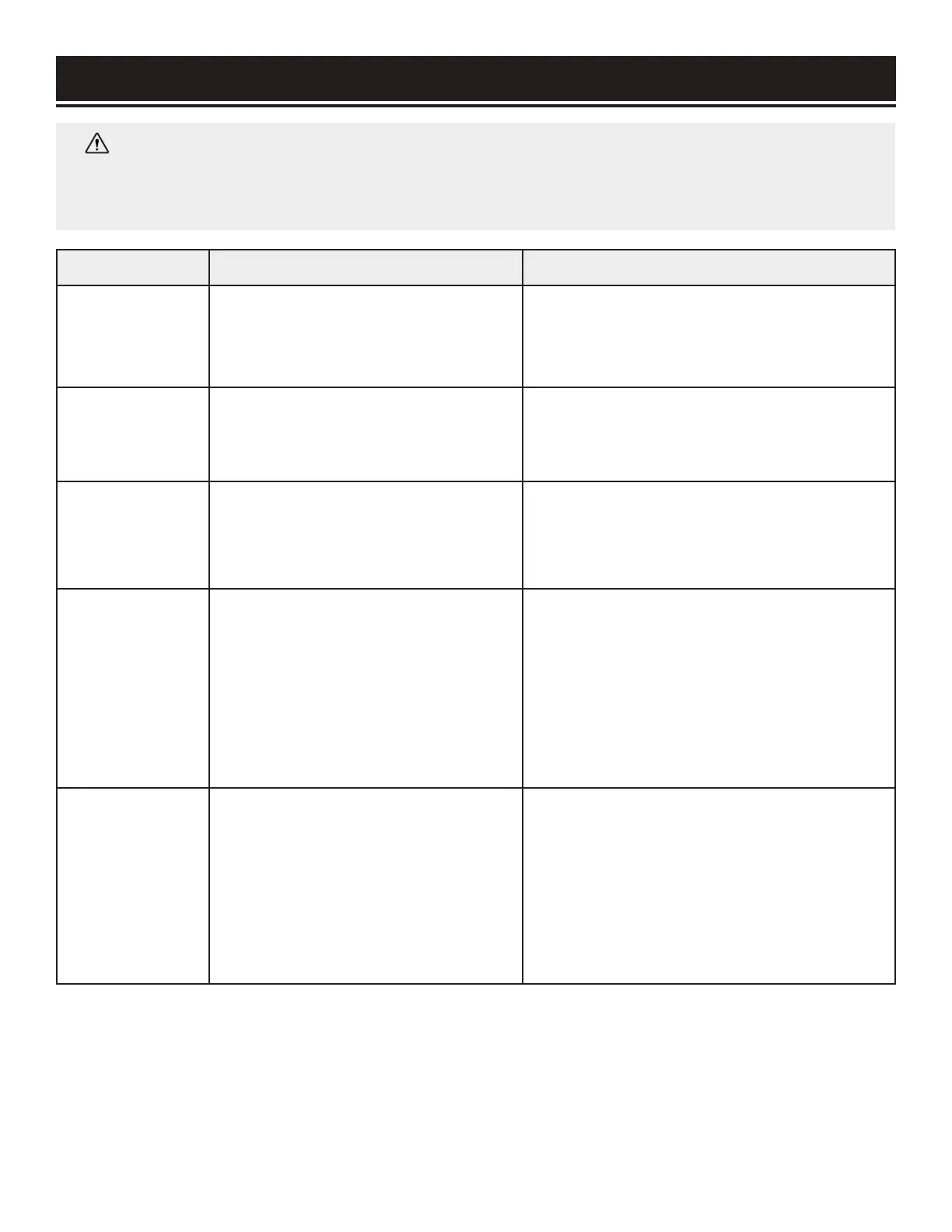

TROUBLESHOOTING

PROBLEM CAUSE SOLUTION

Drill bit binds in

the workpiece

1) The workpiece is pinching the bit

2) Excessive feed pressure

1) Support or clamp the workpiece

2) Feed more slowly

Spindle returns

too slowly or too

quickly

Coil spring has improper tension Adjust the coil spring tension (see p .17)

Chuck falls off

spindle

Dirt, grease, or oil on the tapered sur-

face on the spindle or in the chuck

Clean the tapered surface of both the chuck and

spindle with a household detergent

Motor will not

run

1) Defective or broken switch

2) Defective or damaged power cord

3) Open circuit, loose connections, or

burned out motor

4) Low voltage

5) Bad starting capacitor

1) Contact customer service at 1-800-232-1195

2) Contact customer service at 1-800-232-1195

3) Contact customer service at 1-800-232-1195

4) Check the power line for the proper

voltage. Use another circuit or have a qualified

electrician upgrade the service.

5) Contact customer service at 1-800-232-1195

Motor stalls

1) Short circuit in motor

2) Incorrect fuses or circuit breakers

3) Overloaded circuit

4) Low voltage

1) Contact customer service at 1-800-232-1195

2) Replace with correct fuse or circuit breaker

for the circuit

3) Turn off other machines and retry

4) Check the power line for the proper

voltage. Use another circuit or have a qualified

electrician upgrade the service.

23

WARNING: Stop using the tool immediately if any of the following problems occur. Repairs

and replacements should only be performed by an authorized technician. For any questions, please

contact our customer service at (800) 232-1195, M-F 8-5 CST or email us at

techsupport@wenproducts.com.

Loading...

Loading...