17

OPERATION

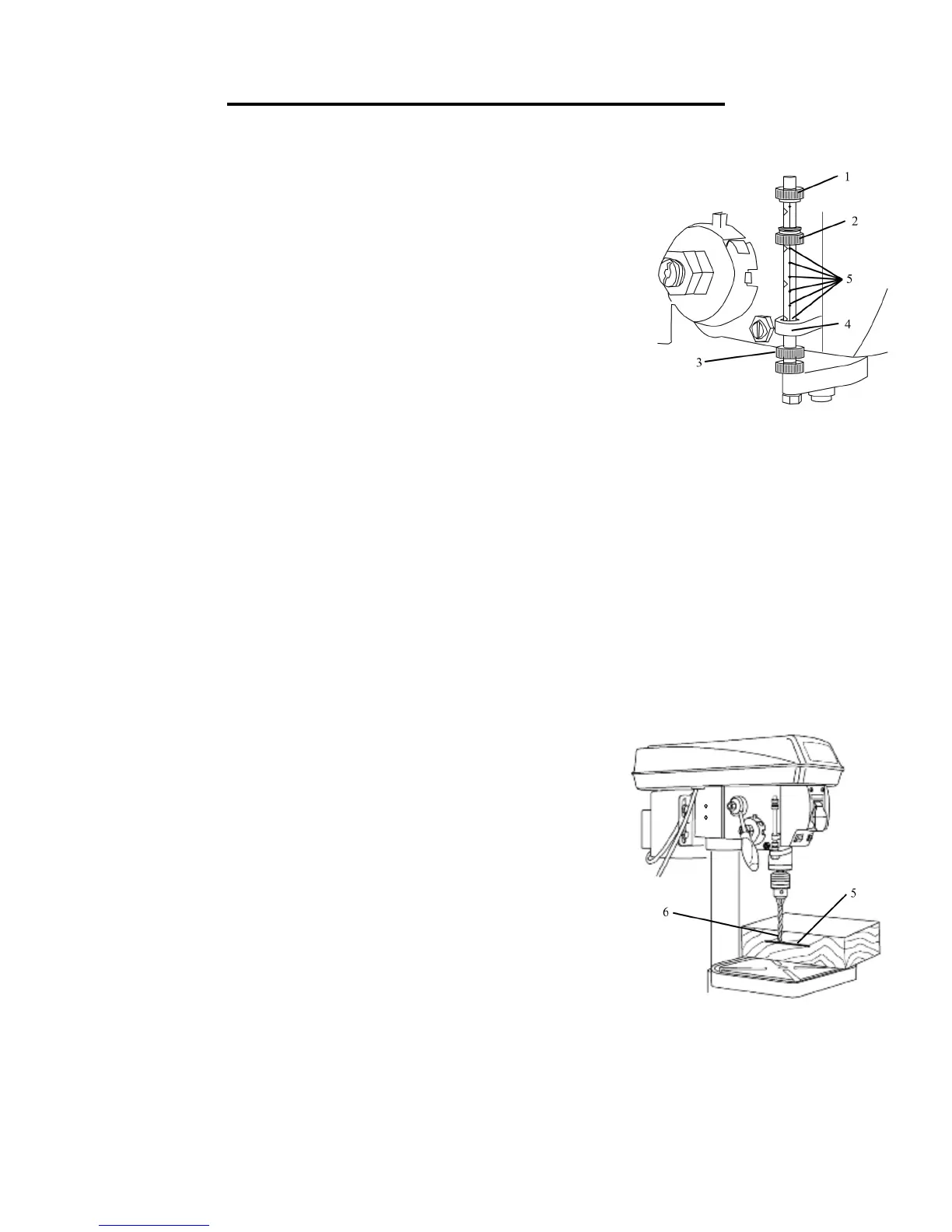

ADJUST THE DRILLING DEPTH (Fig. 22)

The depth gauge controls the maximum distance the drill bit will move up

or down.

To stop the drill bit at a pre-measured depth, loosen the depth scale knob

(1) by push button (2) until the bottom of the knob is aligned with the de-

sired depth mark (3) on the gauge scale.

Drilling an unmeasured blind hole (not all the way through the workpiece)

to a given depth can be done using either the depth scale method or the

workpiece method.

DEPTH SCALE METHOD (Fig. 22)

1. Make sure the 0 (“ or mm) mark on the depth gauge rests at the top edge

of the metal support (4) when the quill is fully retracted.

2. Put the workpiece on the table and raise the table until the tip of the drill

bit just touches the top of the workpiece. Lock the table in place.

3. Determine the drill depth for this workpiece.

4. Rotate the depth knob (2) until it is aligned with the desired depth mark

(3) (for example, 1”) on the gauge scale.

5. The chuck will be stopped at the distance selected on the depth scale.

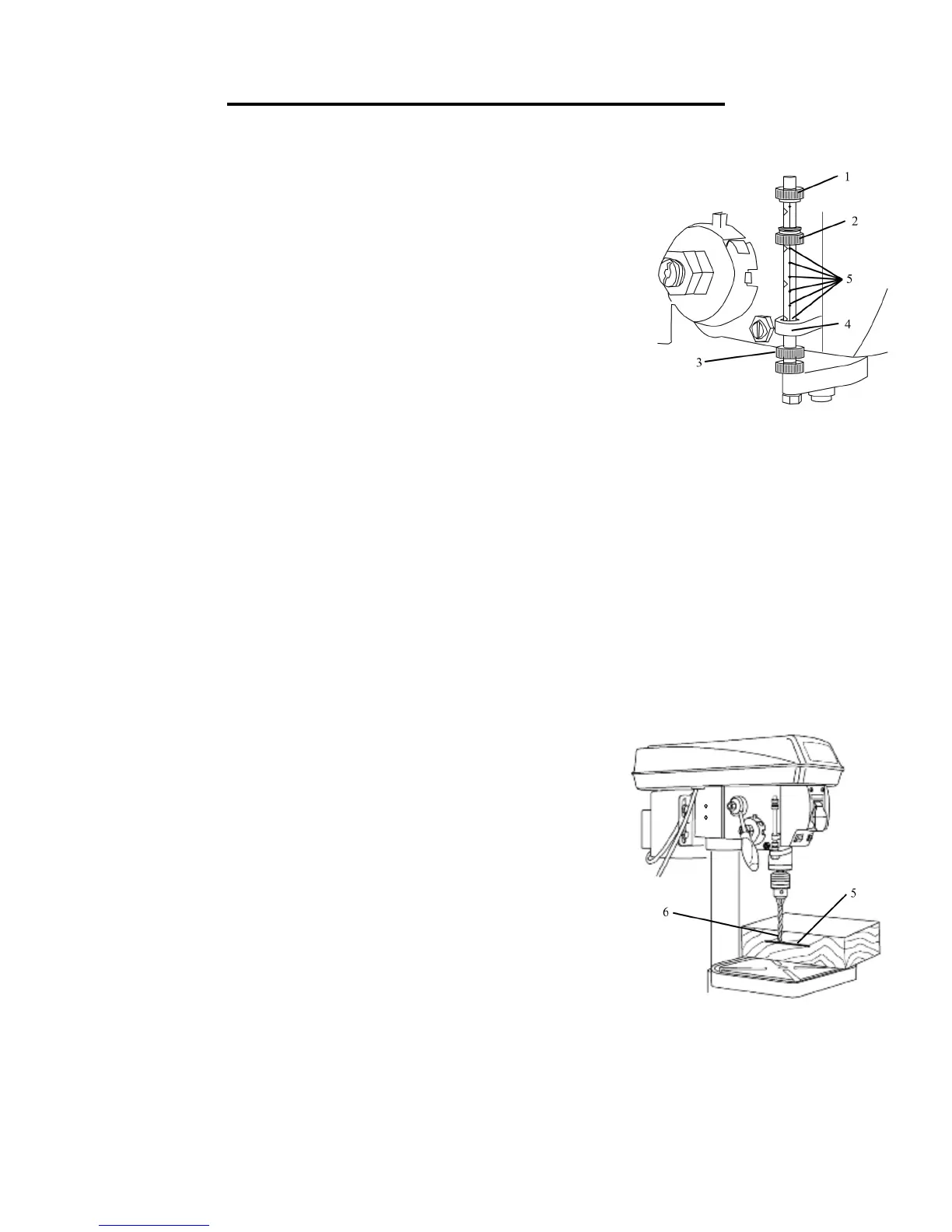

WORKPIECE METHOD (Fig. 22 and 23)

1. Mark the desired depth (5) of the drill hole on the side of the workpiece.

2. With the drill press in the OFF position, bring the drill bit (6) down until

the tip is even with the mark.

3. Holding the feed handles at this position, rotate the depth knob (2) until

it meets the metal support.

4. The chuck and the drill bit will now be stopped at the distance selected

on the depth scale.

Fig. 21

Fig. 22

Fig. 23

Fig. 20

Loading...

Loading...