2. Close the bleed screw after operating the log splitter.

NOTE: Check the bleed screw and make sure it is closed before and during transportation of the log splitter.

Hydraulic fluid may leak through the bleed screw opening if the bleed screw is not fully tightened.

WARNING: Read and thoroughly understand all instructions and safety information before operat-

ing this log splitter. Failure to do so may cause serious injury or death. Do not allow anyone to operate

this log splitter who has not read this manual.

As with all power equipment, a log splitter can be dangerous if assembled or used improperly. Do not operate this

log splitter if you have doubts or questions concerning safe operation. Call our customer service department at

1-800-232-1195 to address these concerns.

OPERATION

CHECKING THE LEVEL OF HYDRAULIC FLUID

The hydraulic system is a closed system consisting of the oil tank, oil pump

and control valve. This log splitter has been filled with AW32 hydraulic

fluid during the manufacturing process. Before each operation, check the

hydraulic fluid and add more if the level is low.

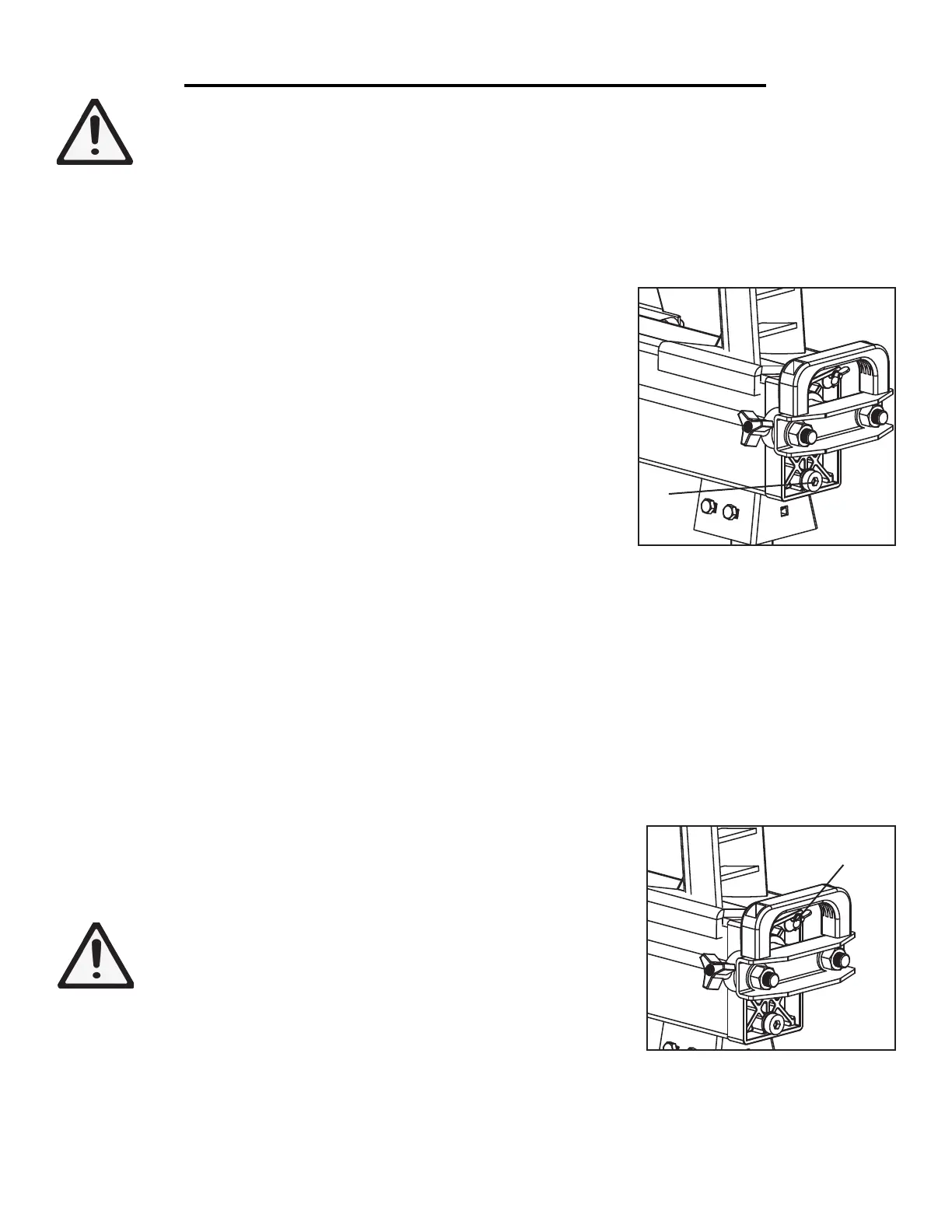

1. Put a collection bowl below the fluid drain (Fig. 4 - 1). Lift up on the

handle of the log splitter so it is in the diagonal position. Make sure the ma-

chine is stable and will not fall.

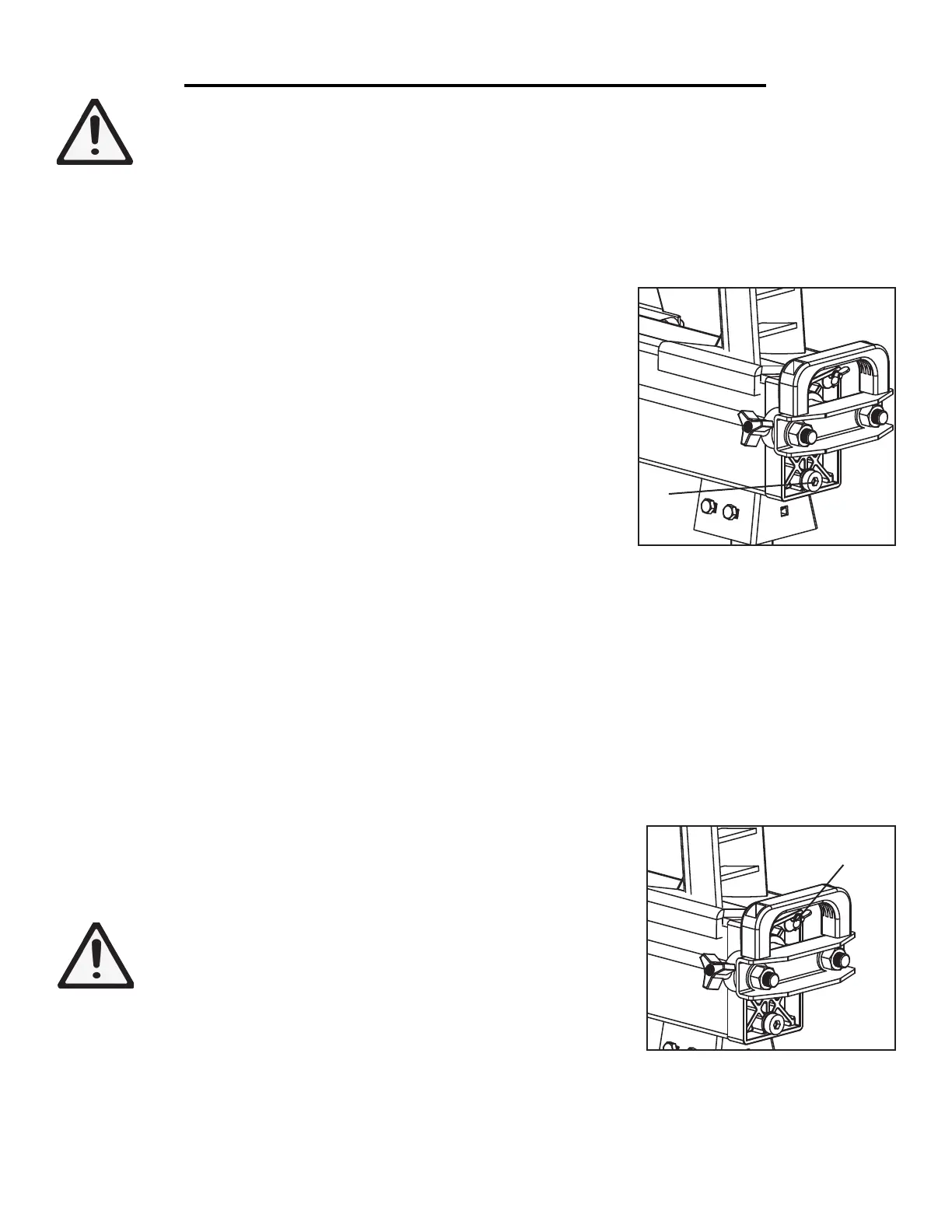

LOOSENING THE BLEED SCREW

1. Turn the bleed screw (Fig. 5 - 1) counterclockwise one or two turns to allow

air to be released from the hydraulic system. NOTE: While the log splitter is

in use, there should be a detectable flow of air through the bleed screw.

WARNING: Always loosen the bleed screw prior to operation.

This will remove any air trapped in the hydraulic system. Failure

to release air from the hydraulic system may damage the hydraulic

seals, permanently damaging the Log Splitter.

Fig. 4

2. Remove the fluid drain bolt (Fig. 4 - 1) and wipe the dipstick.

CAUTION: hydraulic fluid might flow out.

3. Put the dipstick back in the tank and pull it out again.

4. Check the fluid level on the dipstick. It should be between the two notches on the end of the dipstick.

5. Add fluid if the level is low. Replace the dipstick and tighten the fluid drain knob.

6. Check hydraulic connections and fittings regularly for air tightness. Tighten when necessary.

Remember to use AW32 fluid for operation at temperatures above 40°F, and Dexron® automatic transmission

fluid for operation below 40°F.

1

Fig. 5

1

10

Loading...

Loading...