12

OPERATION

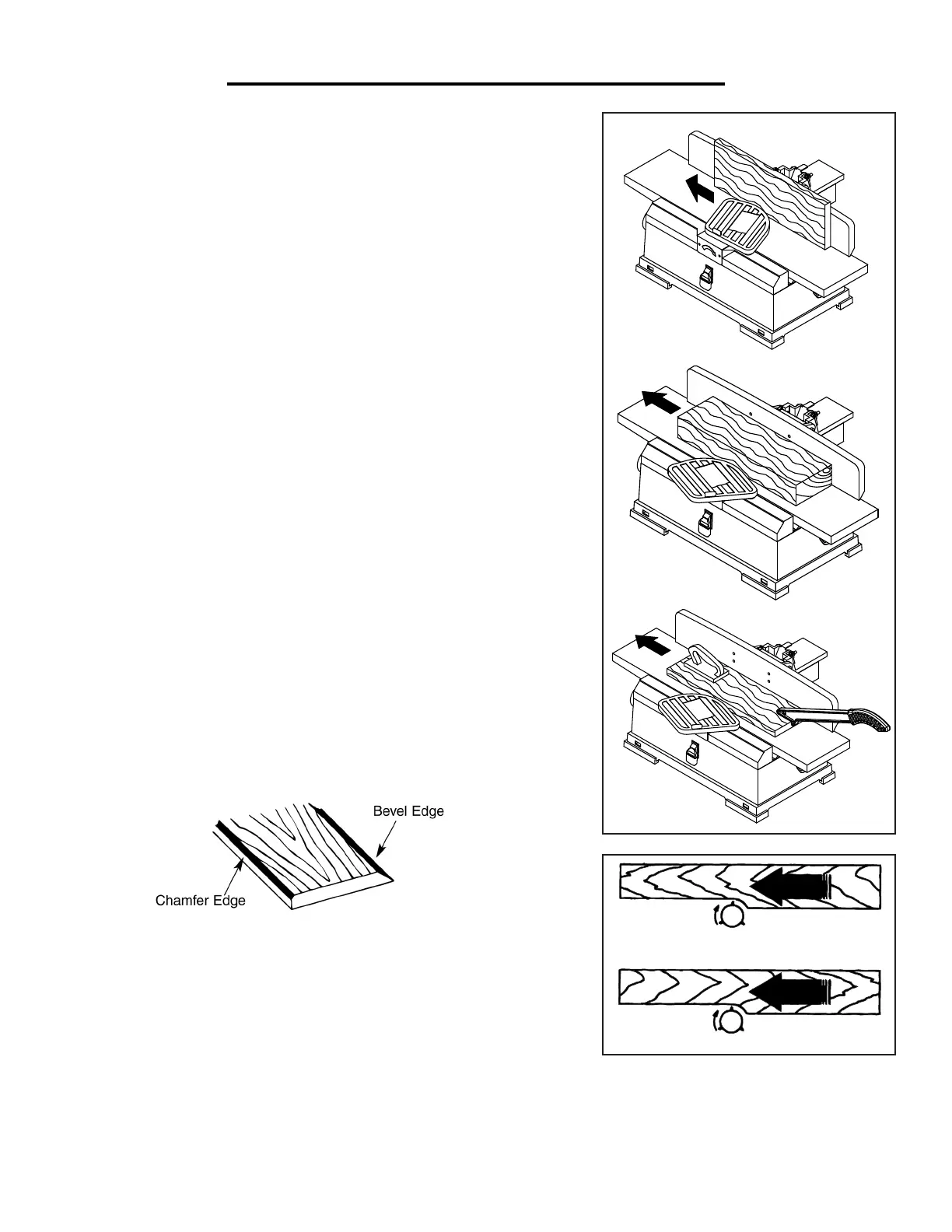

FEEDING WORK

Feed rate refers to the rate at which wood is passed over the blades.

An even feed produces a uniform finish. To feed the work piece:

1. Hold the work piece firmly down on the feed table and against the

fence.

2. Feed the work piece at an even rate over the cutting head. Any hesi-

tation or stopping will cause a “step” to be cut in the work piece.

3. As your trailing hand passes over the cutterhead, remove your

leading hand and place behind your trailing hand and repeat until the

entire length of the workpiece has been cut. Use a push block and a

push stick to hold and feed the workpiece when jointing wood that is

narrower than 3 inches or thinner than 3 inches (Fig. L).

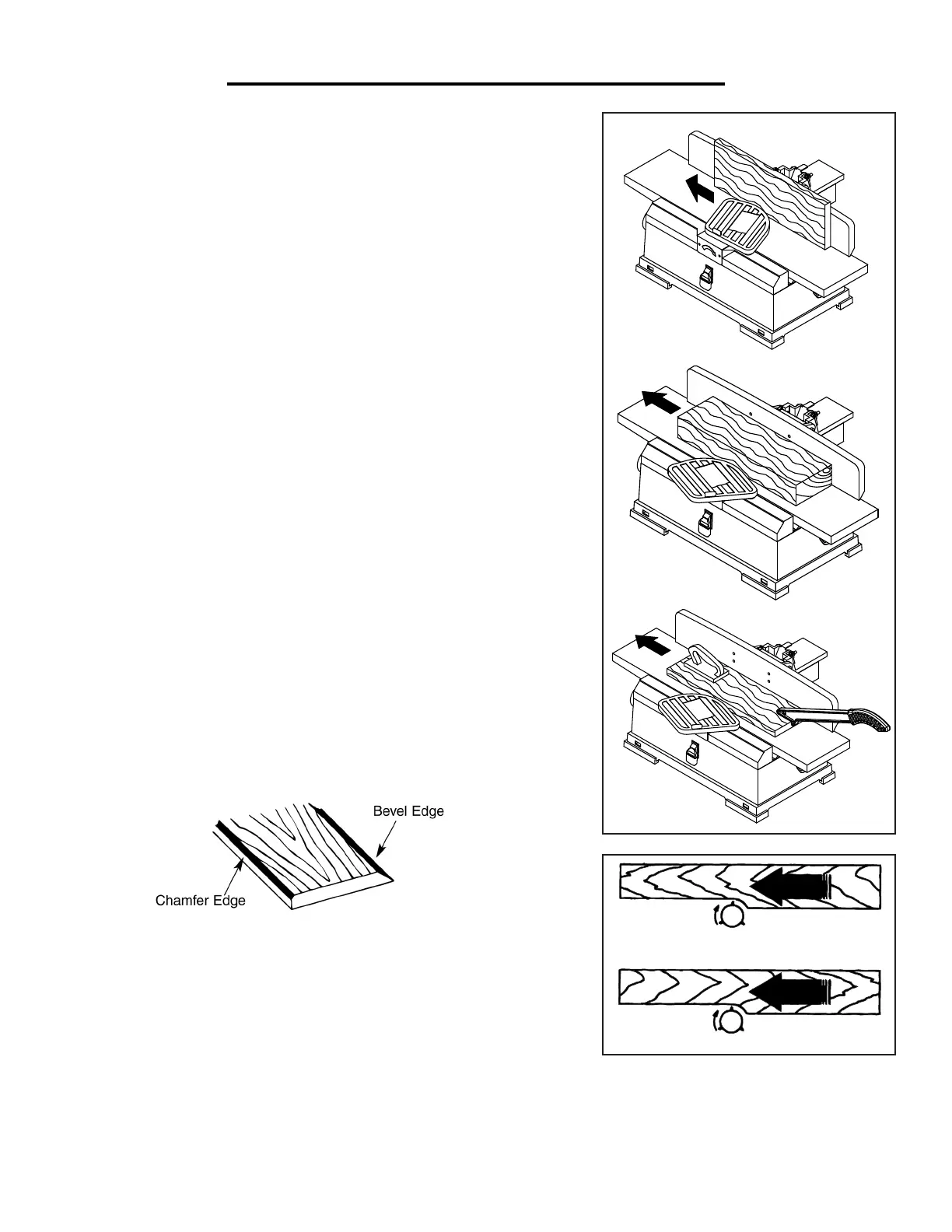

4. Cut with the grain whenever possible (Fig. M). Do not joint end

grain, otherwise the workpiece may split and shatter. If the nature of

the workpiece requires you to joint against the grain, take extremely

light cuts and feed slowly. When using long work pieces, use extra

supports at both ends of the jointer.

BEVELING AND CHAMFERING

The fence on the jointer is adjustable from 45 degrees inward to 45

degrees outward. Adjust the fence to the desired angle and tighten the

tilting handle.

Beveling refers to cutting the entire edge of a board at an angle. Bev-

eling may require several passes due to the depth of the cut needed.

Chamfering refers to removing only the corner of the edge of a board.

Normally a chamfer is made on one pass; so a 1/16-inch deep cut is

made, making the edge stair step.

USING A VACUUM HOSE

A standard dust collection hose can be attached to the 2-1/2-inch

diameter exhaust port underneath the outfeed table. The jointer will

perform properly at all depths of cuts up to 1/8 inch when using a dust

collection system. To attach a dust collection system, insert the dust

collection hose to the exhaust port on the rear of the jointer. Turn

the dust collecting system on before starting the jointer. Periodically

replace and empty the bag in the collection system.

S

1fi

借(通)用件登记

爆炸图序号

机

种

旧底图总号

底图总号

签 字

日 期

区

FEED

FEED

Rotation

With the Grain

Against the Grain

Rotation

Fig. L

Fig. M

Loading...

Loading...