THE ENGINE

A

The oil pump is

of

the eccentric rotor, non-draining

type and is driven from the camshaft.

A full-flow oil filter

is

mounted

on

the side

of

the

crankcase

The fuel injection pump

is

of

the C.A.V. distributor

type incorporating an automatic advance device and a

governor, both

of

which are hydraulically operated. The

pump

is

flange-mounted

on

the right-hand side

of

the

engine

and

is

driven 'by the camshaft through a shaft and

gear mounted transversely in the crankcase.

The fuel lift pump

is

of

the A.C. mechanical type and

is

driven by the engine camshaft. Fuel oil

is

delivered to

the injection pump via

an

external filter

of

the C.A.V.

bowl-less type, having a renewable paper element.

C.A.

V.

Pintaux-type fuel injection nozzles are used.

and a leak-off pipe returns any back-leakage

of

fuel from

the injector nozzles to the supply side

of

the fuel system.

The leak-off pipe is connected to the main fuel filter to

provide continuous air-venting

of

the filter

and

to prevent

the build-up

of

excessive pressure inside the filter.

A centrifugal fresh water pump mounted on the front of

the cylinder block and the

raw

water pump mounted below

the combmatlon manIfolds and expansion tank,

along

with

the alternator

are

belt

driven

from the crankshaft pully.

The cooling system

is

controlled by a thermostat

in

the

cylinder head.

Section A.3

LUBRICATION SYSTEM

The oil supply

is

carried in the sump below the

cylinder block

and

the filler cap is fitted

on

the valve

rocker cover. The oil level indicator rod

is

on

the right-

hand side

of

the engine

and

is marked

to

indicate both

the maximum

and

minimum

le~els.

An eccentric-rotor, non-draining-type oil pump,

located

in

the left-hand side

of

the crankcase, is driven

from the camshaft. Oil

is

drawn through a gauze strainer

mounted inside the sump,

and

is delivered through drilled

passages in the crankcase to the fuel injection pump drive

gear lubricator

and

the oil

pump

driving spindle via a

pencil-type filter gauze,

and

to

a non-adjustable, plunger-

type release valve, all

of

which are located

at

the rear

of

the crankcase on the left-hand side.

From

the release valve

oil

is

fed through a drilling across the rear

of

the crank-

case

and

a horizontal feed gallery in the right-hand side

of

the crankcase to the external full-flow-type oil filter.

From the

cle3l1

side

of

the filter

oil

passes through the

oil

cooler into main oil gallery and then through drillings

in

the crankcase

and crankshaft to the main, big-end,

and

camshaft

bearings and the fuel injection

pump

drive coupling.

From

the camshaft rear bearing oil

at

reduced pressure

is

fed through drilled passages in the crankcase, cylinder

head, rocker shaft rear bracket,

and

rocker shaft

to

the

valve rockers and adjusting screws. Surplus oil from the

valve rockers returns

to

the sump via the push-rod

tunnels to lubricate the tappets.

From

the front camshaft

bearing oil

is

supplied

at

reduced pressure

to

the timing

chain tensioner, through a drilled passage

in

the front

of

the cylinder block, to lubricate the timing chain. Surplus

oil from the timing chain returns

to

the sump through.

two holes in the front main bearing cap. Lubrication

of

the cylinder bores

is

effected by

jet

holes drilled in the

connecting rod big-end bearings.

Section A.4

DRAINING

THE

SUMP

The

sump

is

pumped

out

by

attaching

a 3/8

I.D.

hose

over

the

dip

stick

tube.

This

opera-

tion

should

be

performed

immediately

after

a

run

while

oil is

hot.

Refill

at

once

with

new

oil

of

the

same

brand

and

grade.

Section A.S

EXTERNAL

OIL

FILTER

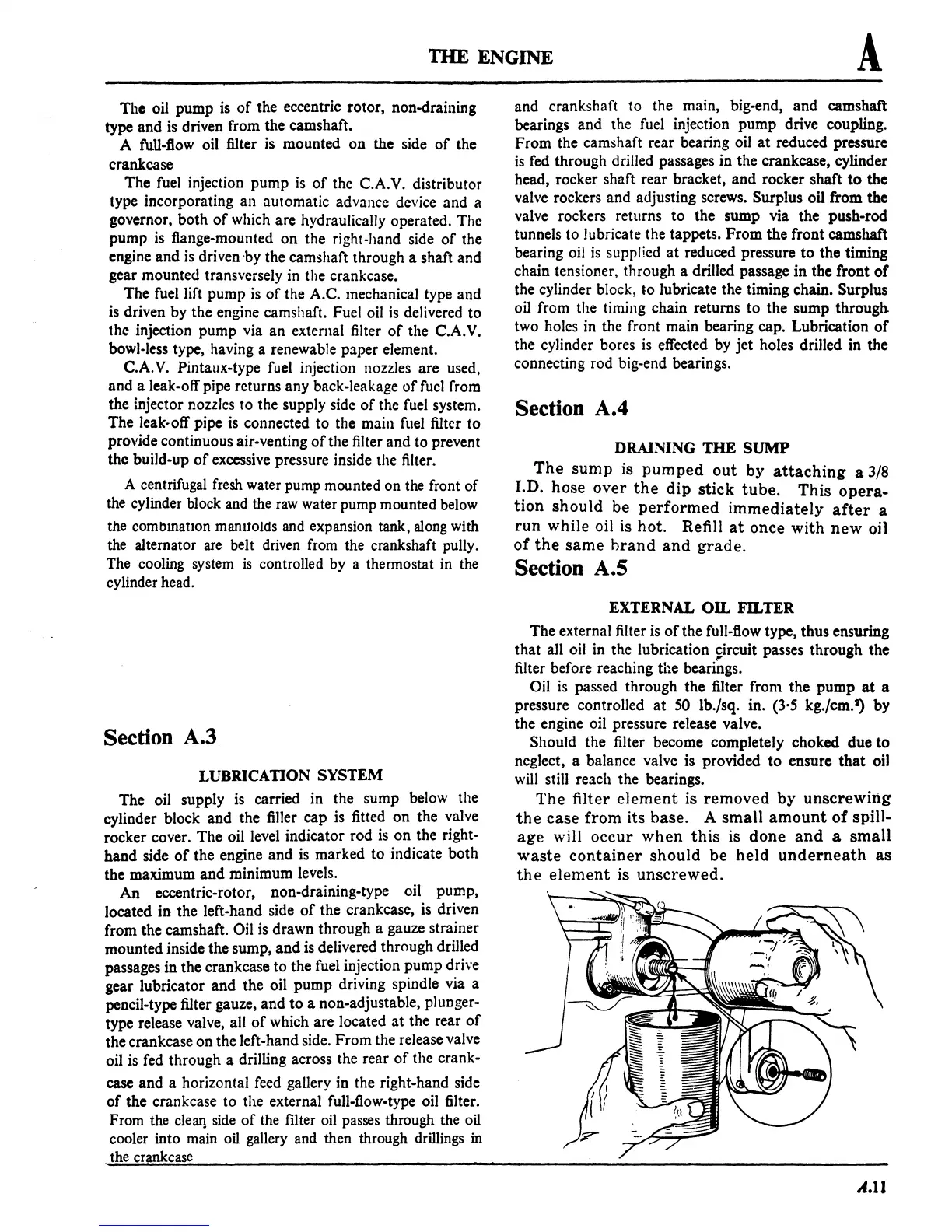

The external filter

is

of

the full-Bow type, thus ensuring

that all oil in the lubrication

~ircuit

passes through the

filter before reaching the bearings.

Oil is passed through the filter from

the

pump

at

a

pressure controlled

at

50 lb./sq. in. (3'5 kg./em.') by

the engine oil pressure release valve.

Should the filter become completely choked

due

to

neglect, a balance valve is provided

to

ensure

that

oil

will still reach the bearings.

The

filter

element

is

removed

by

unscrewing

the

case

from

its

base.

A

small

amount

of

spill-

age

will

occur

when

this

is

done

and

a

small

waste

container

should

be

held

underneath

as

the

element

is

unscrewed.

A.11

Loading...

Loading...