A

THE ENGINE

~

: : .

II;---H---

I,

I

f---G

--

-

l' F

-_

..

_

.•.

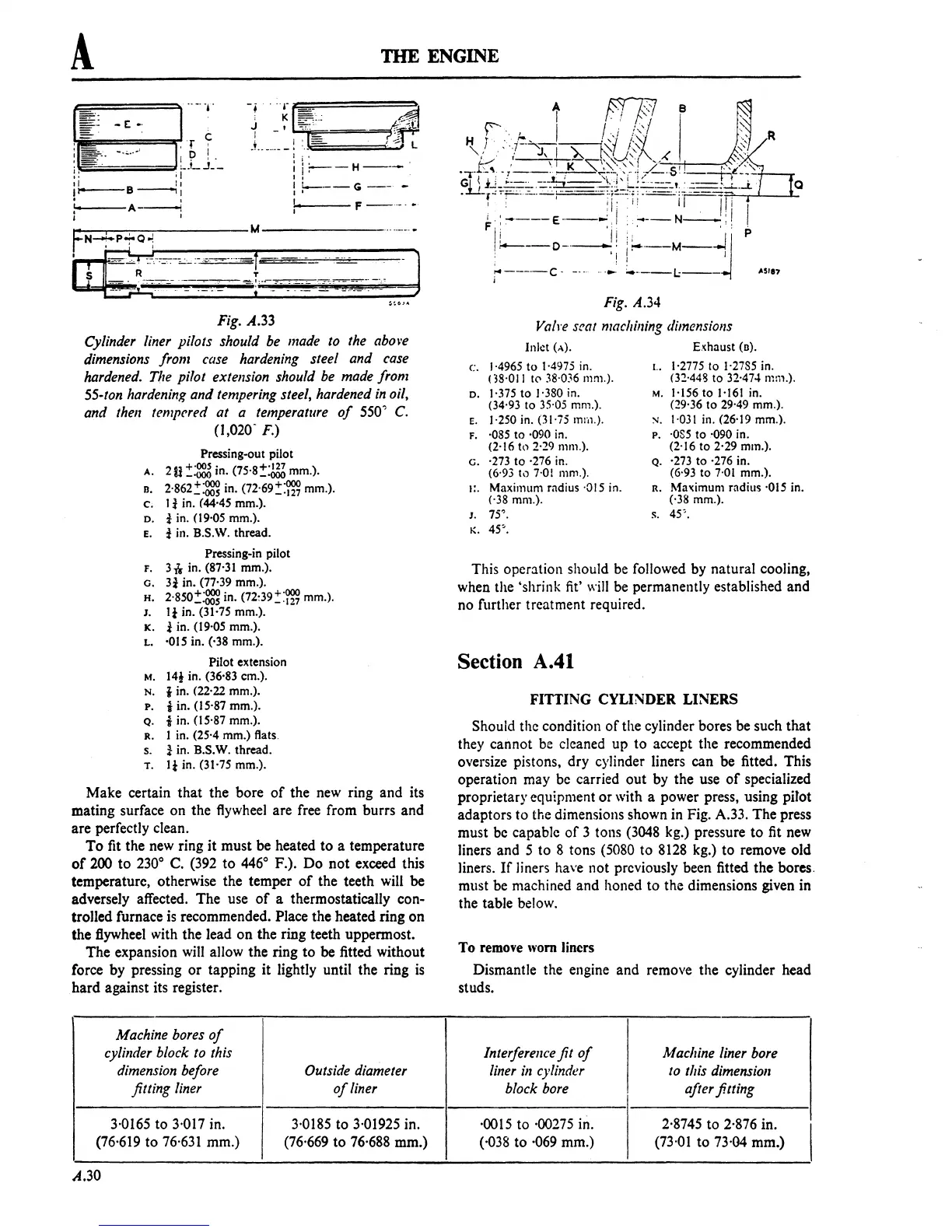

Fig.

A.33

Cylinder

liner

pilots should

be

made

10

the

above

dimensions

from

case

hardening

steel and

case

hardened.

The

pilot extension

should

be

made

from

55·ton

hardening

and

tempering

steel,

hardened

in

oil,

and

then

tempered at a

temperature

of

550'

C.

(1,020- F.)

Pressing-out pilot

A. 2 U

:~

in.

(75'8::~

mm.).

o.

2'862::~

in.

(72'69::m

mm.).

c. 1 i in. (44'45 mm.).

D.

i in. (19'05 mm.).

E. i in. B.S.W. thread.

Pressing-in pilot

F. 3 * in. (87'31 mm.).

o.

3i

in. (77·39 mm.).

H.

2'850::~

in.

(72:39::m

mm.).

J.

Ii

in. (31·75 mm.).

K.

i in. (19'05 mm.).

L.

'015 in. ('38 mm.).

Pilot extension

M.

14l

in. (36·83 em.).

N.

tin.

(22'22 mm.).

p.

i in. (15'87 mm.).

Q.

i in. (15'87 mm.).

R. I in. (25'4 mm.) flats.

s. ! in. B.S.W. thread.

T.

Ii

in. (31'75 mm.).

Make certain that the bore

of

the new ring and its

mating surface on the flywheel are free from burrs and

are perfectly clean.

To

fit the new ring

it

must be heated

to

a temperature

of

200

to

230

0

C.

(392

to

446

0

F.). Do

not

exceed this

temperature, otherwise the temper

of

the teeth

will

be

adversely affected. The use

of

a thermostatically con-

trolled furnace

is

recommended. Place the heated ring on

the flywheel with the lead on the ring teeth uppermost.

The expansion

will

allow the ring

to

be fitted without

force by pressing

or

tapping it lightly until the ring

is

hard against its register.

Machine

bores

of

cylillder

block

to

this

dimension

before

Outside

diameter

jilling

liner

of

liner

3·0165

to

3·017

in.

3·0185

to

3·01925

in.

(76·619

to

76·631

mm.)

(76'669

to

76·688

mm.)

A.30

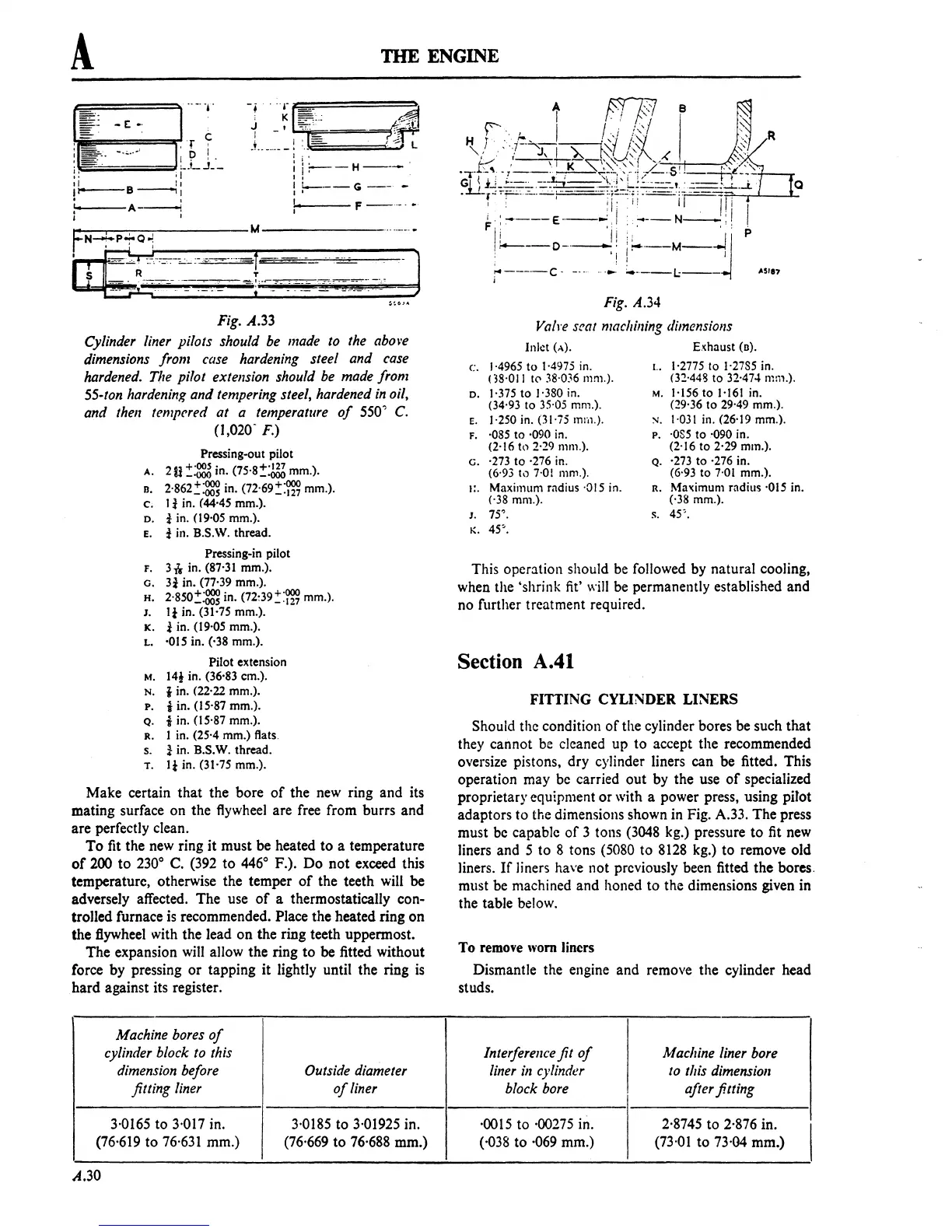

Fig.

A.34

Va/re

seat

machining

dimensions

Inlet (A).

c.

1·4965

to

1·4975 in.

(38'011

to

38·036

111m.).

D.

1·375

to

1·380 in.

(34'93 to 35·05 mm.).

E.

1·250 in. (31·75

!TIm.).

F. ·085

to

·090 in.

(2'161l) 2·29 mm.).

G.

·273

to

·276 in.

(6'93 10

7·01

mm.).

I:.

Maximum radius ·015 in.

('38 mm.).

J.

75'.

K.

45'.

E.~haust

(D).

I.. 1·2775

to

1'2785 in.

(3:!·448 to 32·47-'

ml11.).

M.

1·156

to

1-161

in.

(:!9'36

to

29'49 mm.).

:-I.

1·031

in. (26'19 mm.).

p.

·OS5

to

'090 in.

(2'16

to

2'29 mm.).

Q. ·273

to

·276 in.

(6'93

to

7·01

mm.).

R. Maximum radius ·015 in.

('38 mm.).

s.

45'.

This operation should be followed by natural cooling,

when the 'shrink

fit'

will

be permanently established and

no further treatment required.

Section A.41

FITTING CYLINDER LINERS

Should

the condition

of

the cylinder bores be such that

they cannot be cleaned up

to

accept the recommended

oversize pistons, dry cylinder liners can be fitted. This

operation may be carried out by the use

of

specialized

proprietary equipment or with a power press, using pitot

adaptors to the dimensions shown in Fig. A.33. The press

must be capable

of

3 tons

(3048

kg.) pressure

to

fit new

liners and 5

to

8 tons

(5080

to

8128

kg.) to remove old

liners.

If

liners have not previously been fitted the bores.

must be machined and honed

to

the dimensions given in

the table below.

To

remove

worn

liners

Dismantle the engine and remove the cylinder head

studs.

Interferellce

jit

of

Machine

liner

bore

liner

ill

cylinder

to

this

dimensioll

block

bore

after fitting

·0015

to

·00275

ill.

2·8745

to

2·876

in.

I

('038 to

·069

mm.)

(73'01

to

73·04

mm.)

Loading...

Loading...