D

THE FUEL SYSTEM

13----------~~~~~

12

1-_---2

1'1------3

4

IO---+~_

"'=:---

5

,_

......

9

6

8----

--------7

_

.793

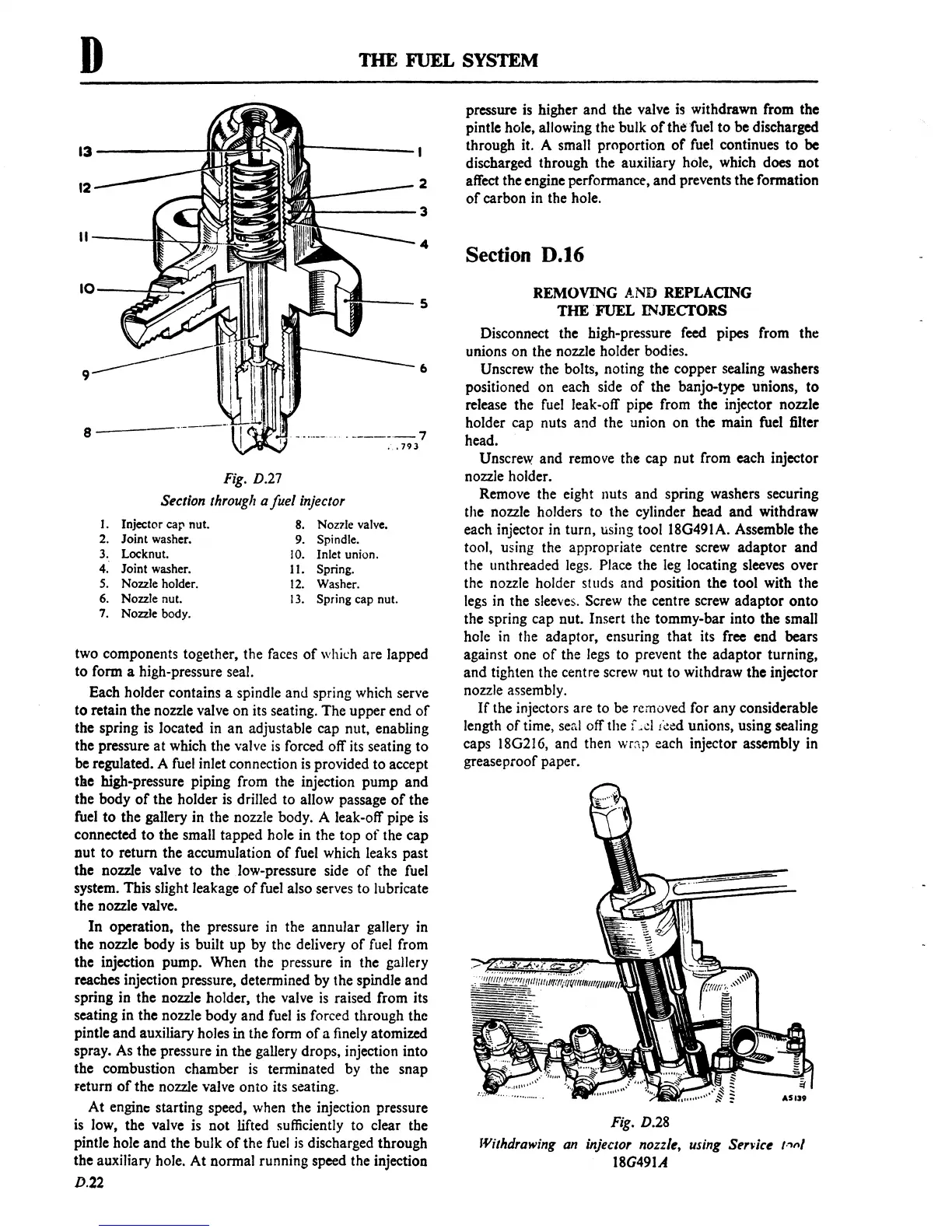

Fig.

D.27

Section

through a fuel injector

I.

Injector cap nut.

8.

Nozl.le

valve.

2.

Joint washer. 9. Spindle.

3.

Locknut.

10.

Inlet union.

4.

Joint washer. 11. Spring.

S.

Nozzle holder.

12.

Washer.

6.

Nozzle nut.

13.

Spring cap nut.

7.

Nozzle

body.

two components together, the faces

of

which are lapped

to form a high-pressure seal.

Each holder contains a spindle and spring which serve

to

retain the nozzle valve on its seating.

The

upper end

of

the spring is located in

an

adjustable cap nut, enabling

the pressure

at

which the valve

is

forced off its seating

to

be regulated. A fuel inlet connection

is

provided to accept

tile high-pressure piping from the injection pump

and

the body

of

the holder is drilled to allow passage

of

the

fuel

to

the gallery in the nozzle body. A leak-off pipe

is

connected

to

the small tapped hole in the top

of

the cap

nut

to

return the accumulation

of

fuel which leaks past

the nozzle valve

to

the Jow-pressure side

of

the fuel

system. This slight leakage

of

fuel also serves to lubricate

the nozzle valve.

In

operation, the pressure in the annular gallery in

the nozzle body

is

built up by the delivery

of

fuel from

the injection pump. When the pressure in the gallery

reaches injection pressure, determined by the spindle and

spring in the nozzle holder, the valve

is

raised from its

seating in the nozzle body and fuel

is

forced through the

pintle

and

auxiliary holes in the form

of

a finely atomized

spray. As the pressure in the gallery drops, injection into

the combustion chamber

is

terminated by the snap

Feturn

of

the nozzle valve onto its seating.

At

engine starting speed, when the injection pressure

is low, the valve is

not

lifted sufficiently to clear the

pintle hole and the bulk

of

the fuel

is

discharged through

the auxiliary hole.

At

normal running speed the injection

D.22

pressure

is

higher

and

the valve is withdrawn from the

pintle hole, allowing the bulk

of

the 'fuel

to

be discharged

through it. A small proportion

of

fuel continues

to

be

discharged through the auxiliary hole, which does

not

affect the engine performance, and prevents the formation

of

carbon in the hole.

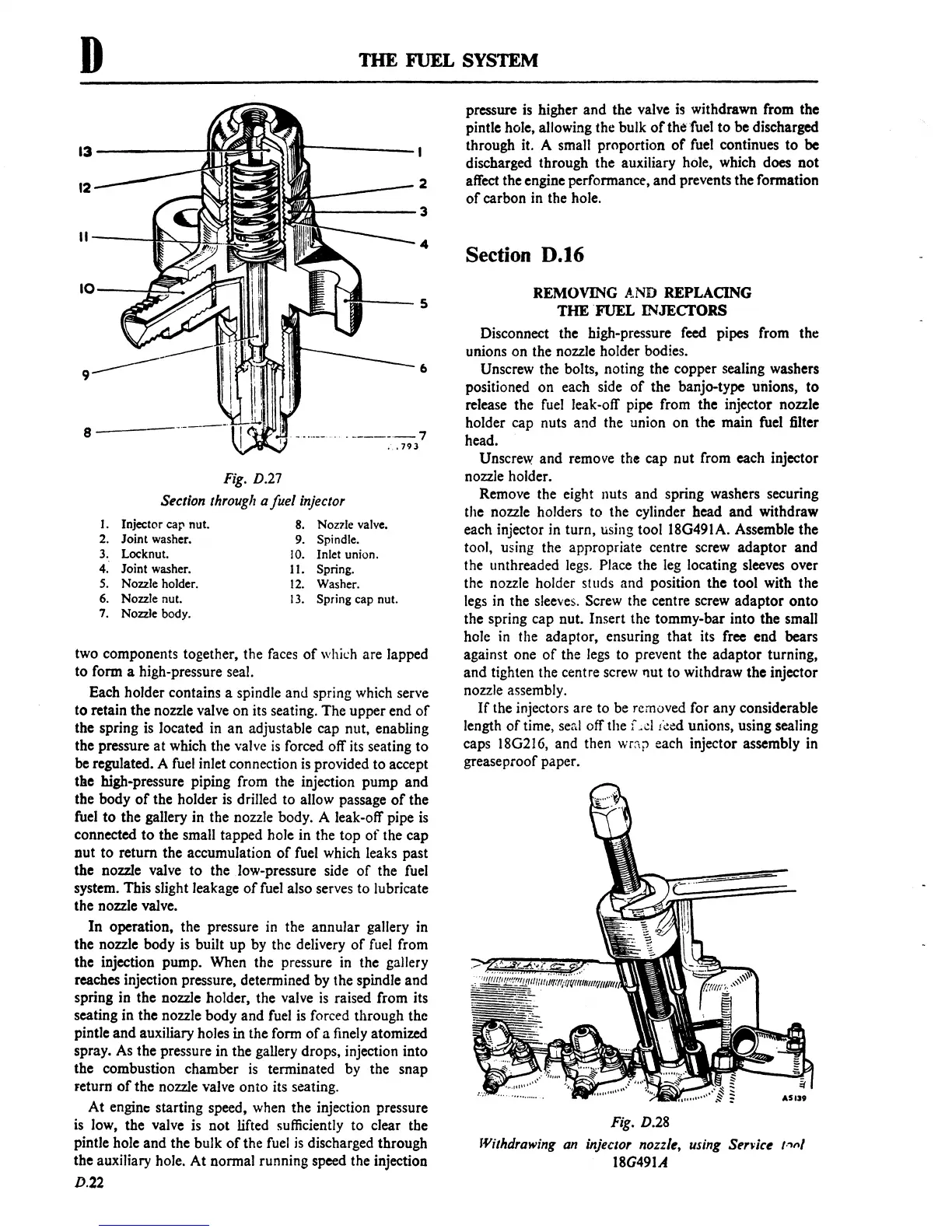

Section D.16

REMOVING AND REPLACING

THE

'FUEL

INJECTORS

Disconnect the high-pressure feed pipes from the

unions on the nozzle holder bodies.

Unscrew the bolts, noting the copper sealing washers

positioned

on

each side

of

the banjo-type unions,

to

release the fuel leak-off pipe from the injector nozzle

holder cap nuts and the union

on

the main fuel filter

head.

Unscrew and remove

the cap

nut

from each injector

nozzle holder.

Remove the eight nuts and spring washers securing

the nozzle holders to the cylinder head

and

withdraw

each injector in turn, using tool 18G491A. Assemble the

tool, using the appropriate centre screw

adaptor

and

the unthreaded legs. Place the leg locating sleeves over

the nozzle holder studs and position the tool with the

legs in the sleeves. Screw the centre screw

adaptor

onto

the spring cap nut. Insert the tommy-bar into the small

hole in the adaptor, ensuring

that

its free end bears

against one

of

the legs to prevent the

adaptor

turning,

and

tighten the centre screw nut to withdraw the injector

nozzle assembly.

If

the injectors are to be removed for any considerable

length

of

time, seal off the f

-,d

t'~ed

unions, using sealing

caps 18G216, and then

wr:\t' each injector assembly in

grease proof paper.

Fig. D.28

Withdrawing an injector nozzle, using Service

,-.,,,/

18G491A

Loading...

Loading...