Refitting

NOTE: When fitting each new bearing liner

ensure

that

its oil holes are lined up with

those in the crankcase.

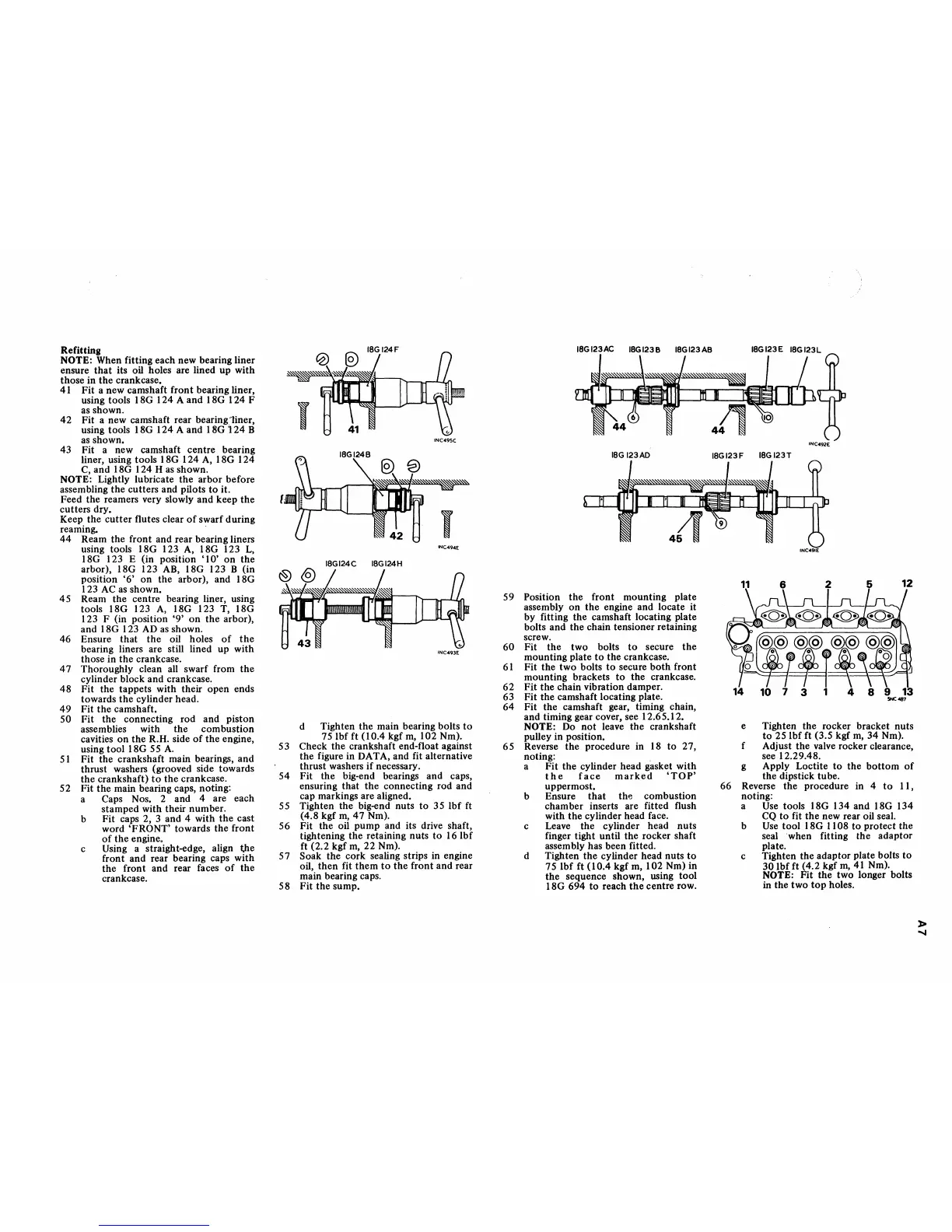

41 Fit a new camshaft front bearing liner,

using tools I

SG

124 A and ISG 124 F

as shown.

42

Fit a new camshaft rear bearing1iner,

using tools 18G 124 A and 18G

i

24

B

as

shown.

43 Fit a new camshaft centre bearing

liner, using tools

ISG 124

A,

ISG 124

C,

and ISG 124 H

as

shown.

NOTE: Lightly lubricate the arbor before

assembling the cutters and pilots

to

it.

Feed the reamers very slowly and keep

the

cutters dry.

Keep the

cutter

flutes clear

of

swarf during

reaming. .

44

Ream the front and rear bearing liners

using tools

ISG 123

A,

ISG 123

L,

ISG 123 E (in position

'10'

on

the

arbor),

ISG 123

AB,

ISG 123 B (in

position

'6'

on

the arbor), and ISG

1 23

AC

as

shown.

45

Ream the centre bearing liner, using

tools

ISG 123

A,

18G 123 T, ISG

123 F (in position

'9'

on

the

arbor),

and

ISG 123

AD

as shown.

46 Ensure that the oil holes

of

the

bearing liners are still lined up with

those in the crankcase.

47

Thoroughly clean all swarf from

the

cylinder block and crankcase.

4S Fit the tappets with their open ends

towards the cylinder head.

49

Fit the camshaft.

50 Fit the connecting rod and piston

assemblies with the combustion

cavities

on

the R.H. side

of

the engine,

using tool

ISG

55

A.

5 I Fit the crankshaft main bearings, and

thrust washers (grooved side towards

the crankshaft)

to

the crankcase.

52 Fit

the

main bearing caps, noting:

a Caps Nos. 2 and 4 are each

stamped with their number.

b Fit caps 2, 3 and 4 with

the

cast

word

'FRONT' towards the front

of

the engine.

c Using a straight-edge, align

t,he

front and rear bearing caps with

the front and rear faces

of

the

crankcase.

INC495C

I

INC494£

18GI24C

18GI24H

INC493E

d Tighten the main bearing bolts

to

75 Ibf ft

(l0.4

kgf

m,

102 Nm).

53 Check the crankshaft end-float against

the figure in DATA, and fit alternative

thrust washers

if

necessary.

54 Fit the big-end bearings and caps,

ensuring that the connecting rod and

cap markings are aligned.

55

Tighten the big-end nuts

to

35 Ibf ft

(4.S kgf

m,

47

Nm).

56 Fit the oil pump and its drive shaft,

tightening the retaining nuts

to

16 Ibf

ft (2.2 kgf

m,

22

Nm).

57

Soak the cork sealing strips in engine

oil, then

fit

them

to

the front and rear

main bearing caps.

58 Fit the sump.

18GI23AC

18G

123AD

59 Position the front mounting plate

assembly on the engine and locate it

by fitting the camshaft locating plate

bolts and the chain tensioner retaining

60

61

62

63

64

screw.

Fit the two bolts

to

secure

the

mounting plate

to

the crankcase.

Fit the two bolts

to

secure

both

front

mounting brackets

to

the crankcase.

Fit the chain vibration damper.

Fit the camshaft locating plate.

Fit the camshaft gear, timing chain,

and timing gear cover, see 12.65.12.

NOTE: Do not leave the crankshaft

pulley in position.

65 Reverse the procedure in 18

to

27,

noting:

,

a Fit the cylinder head gasket with

the

face

marked

'TOP'

uppermost.

b Ensure

that

the combustion

chamber inserts are fitted flush

with the cylinder head face.

c Leave the cylinder head nuts

finger tight until the rocker shaft

assembly has been fitted.

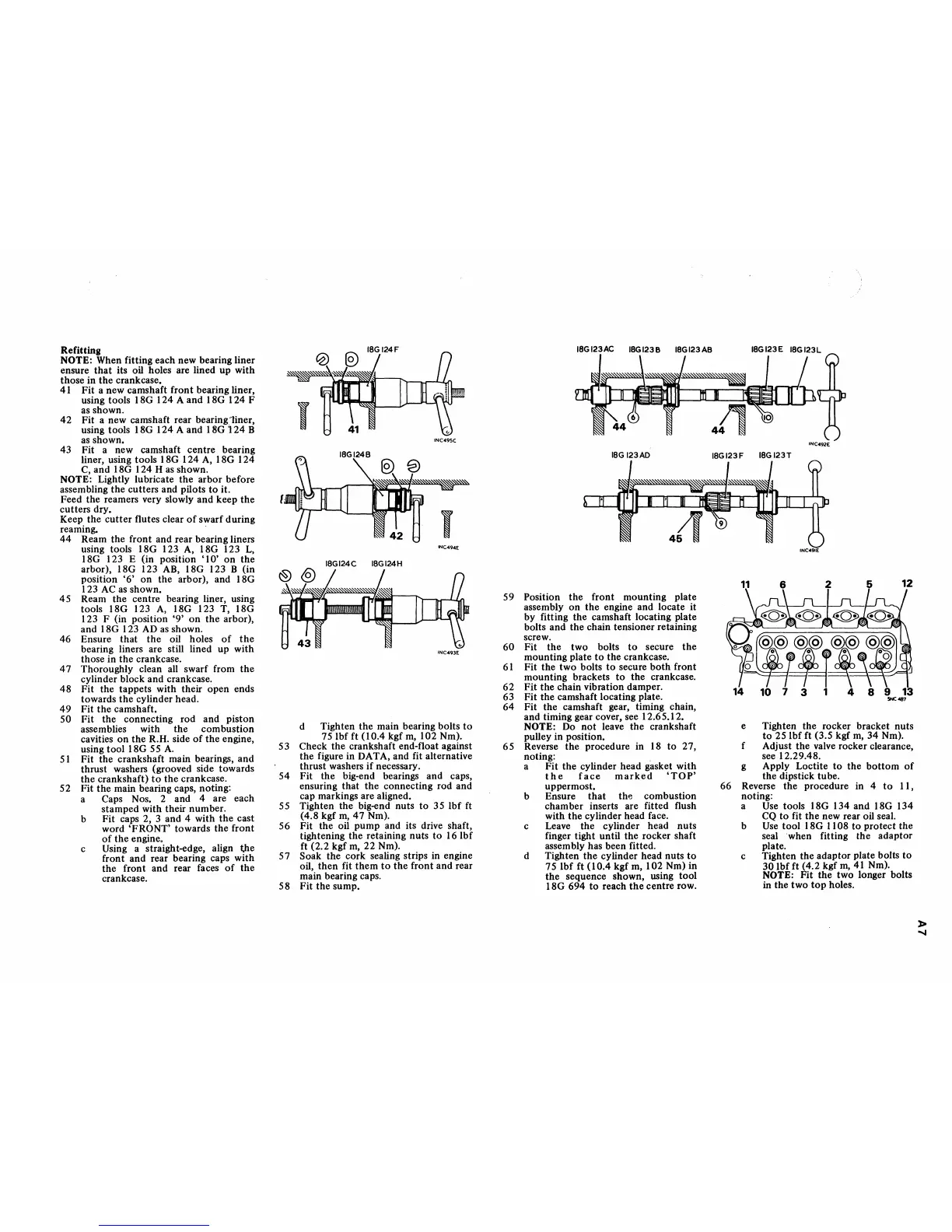

d Tighten the cylinder head nuts

to

75 Ibf ft (10.4 kgf m, 102 Nm) in

the sequence shown, using tool

18G 694

to

reach

the

centre row.

INC492E

18GI23F

18G

123T

INC49tE

e Tighten the rocker bracket nuts

to

25 Ibf ft (3.5 kgf

m,

34 Nm).

f Adjust the valve rocker clearance,

see 12.29.4S.

g Apply Loctite

to

the

bottom

of

the dipstick tube.

66 Reverse the procedure in 4

to

II,

noting:

a

Use

tools 18G 134 and 18G 134

CQ

to

fit the new rear oil seal.

b

Use

tool 18G

11

OS

to

protect the

seal 'when fitting the adaptor

plate.

c Tighten the adaptor plate bolts

to

30 Ibf ft (4.2 kgf

m,

41

Nm).

NOTE: Fit the two longer bolts

in the two

top

holes.

»

"'"

Loading...

Loading...