20

Remove

the

oil pump and its drive

shaft.

21

Remove the big-end bearing caps and

bearing halves.

NOTE:

If

the crankshaft has

to

be

rotated, be careful not to apply any

force which could cause damage

if

a

piston touches a valve.

22 Remove the main bearing caps and

bearing halves, using tools 18G 284

and 18G 284

AC

on

the front and rear

caps if necessary.

23 Lift

out

the crankshaft and remove

the bearing and thrust washer halves.

24

Remove the crankshaft gear.

25 Remove the crankshaft keys and lift

off

the

shim(s}.

Refitting

26 Fit the shim(s}, keys and gear

to

the

crankshaft.

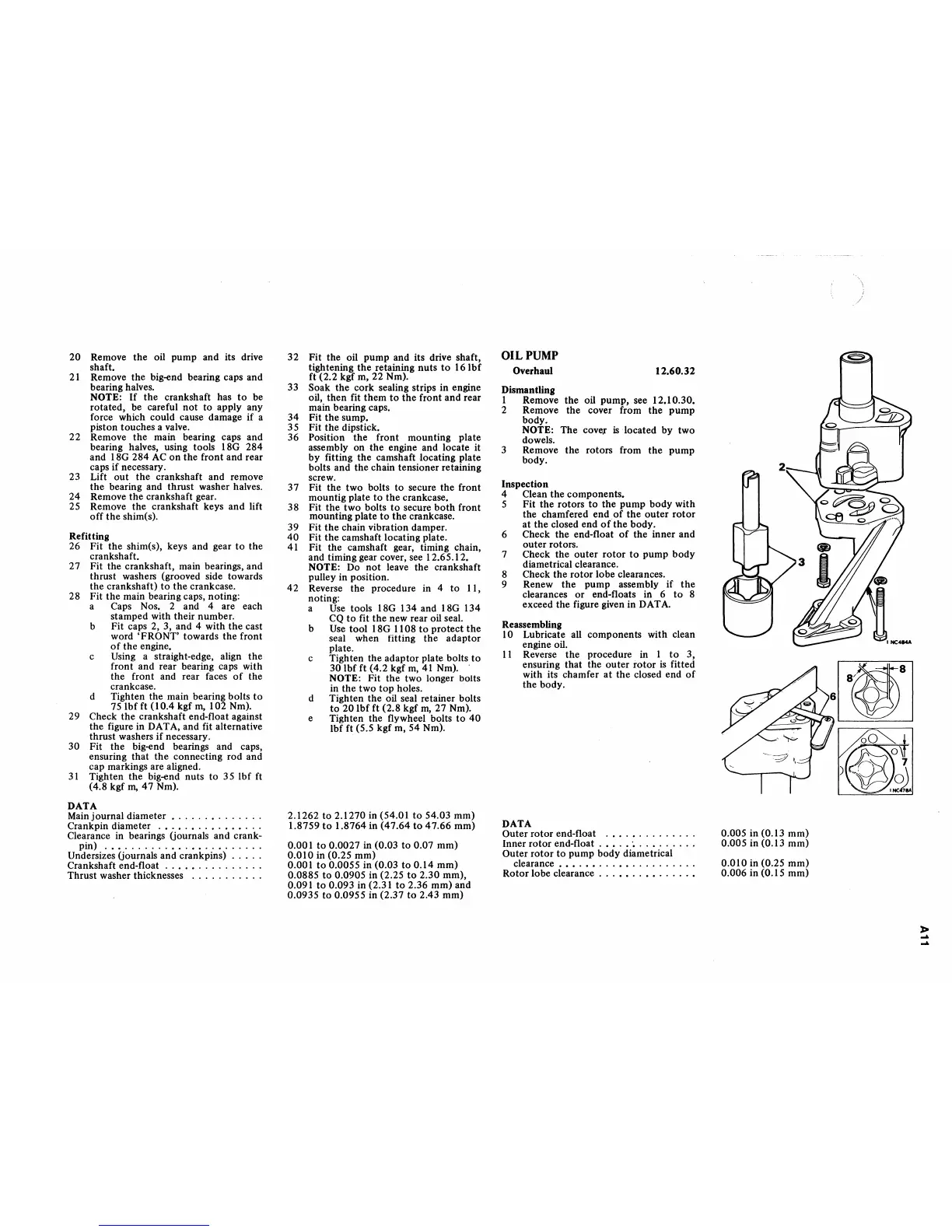

27 Fit the crankshaft, main bearings, and

thrust washers (grooved side towards

the crankshaft)

to

the

crankcase.

28 Fit

the

main bearing caps, noting:

a Caps Nos. 2 and 4 are each

stamped with their number.

b Fit caps 2, 3, and 4 with

the

cast

word 'FRONT' towards the front

of

the engine.

c Using a straight-edge, align the

front and rear bearing caps with

the front and rear faces

of

the

crankcase.

d Tighten the main bearing bolts

to

751bfft

(l0.4

kgf m, 102 Nm).

29 Check the crankshaft end-float against

the figure in

OAT

A,

and fit alternative

thrust washers

if

necessary.

30 Fit the big-end bearings and caps,

ensuring that the connecting rod and

cap markings are aligned.

31

Tighten the big-end nuts to 35 Ibf ft

(4.8 kgf

m,

47

Nm).

DATA

Main

journal diameter

.............

.

Crankpin diameter

.•.•.•....•.....

Clearance in bearings Uournals and crank-

pin}

.••.......••.••..•......

Undersizes Uournals and crankpins}

.....

Crankshaft end-float

..•••..........

Thrust washer thicknesses

..........

.

32 Fit the oil pump and its drive shaft,

tightening the retaining nuts

to

161bf

ft (2.2 kgf m, 22 Nm).

33 Soak the cork sealing strips in engine

oil, then fit them

to

the

front and rear

main bearing caps.

34 Fit the sump.

35 Fit the dipstick.

36 Position

the

front mounting plate

assembly on

the

engine and locate it

by

fitting the camshaft locating plate

bolts and the chain tensioner retaining

screw.

37 Fit the two bolts to secure the front

mountig plate

to

the crankcase.

38 Fit the two bolts

to

secure

both

front

mounting plate

to

the

crankcase.

39 Fit the chain vibration damper.

40

Fit the camshaft locating plate.

41

Fit the camshaft gear, timing chain,

and timing gear cover, see 12.65.12.

NOTE:

00

not

leave the crankshaft

pulley in position.

42

Reverse the procedure in 4 to

II,

noting:

a

Use

tools 18G 134 and 18G 134

CQ

to

fit

the

new rear oil seal.

b

Use

tool

18G 1108

to

protect

the

seal when fitting

the

adaptor

plate.

c Tighten the adaptor plate bolts

to

30 Ibf ft (4.2 kgf

m,

41 Nm). .

NOTE: Fit the two longer bolts

in the two top holes.

d Tighten the oil seal retainer bolts

to

20

Ibf

ft (2.8 kgf

m,

27 Nm).

e Tighten the flywheel bolts

to

40

Ibf ft (5.5 kgf m, 54 Nm).

2.1262 to

2.1270 in (54.01

to

54.03 mm)

1.8759

to

1.8764 in (47.64

to

47.66 mm)

0.001

to

0.0027 in (0.03 to 0.07 mm)

0.010 in (0.25 mm)

0.001

to

0.0055 in (0.03

to

0.14 mm)

0.0885

to

0.0905 in (2.25

to

2.30 mm),

0.091

to

0.093 in (2.31

to

2.36 mm) and

0.0935 to 0.0955 in (2.37

to

2.43 mm)

OIL

PUMP

Overhaul

Dismantling

12.60.32

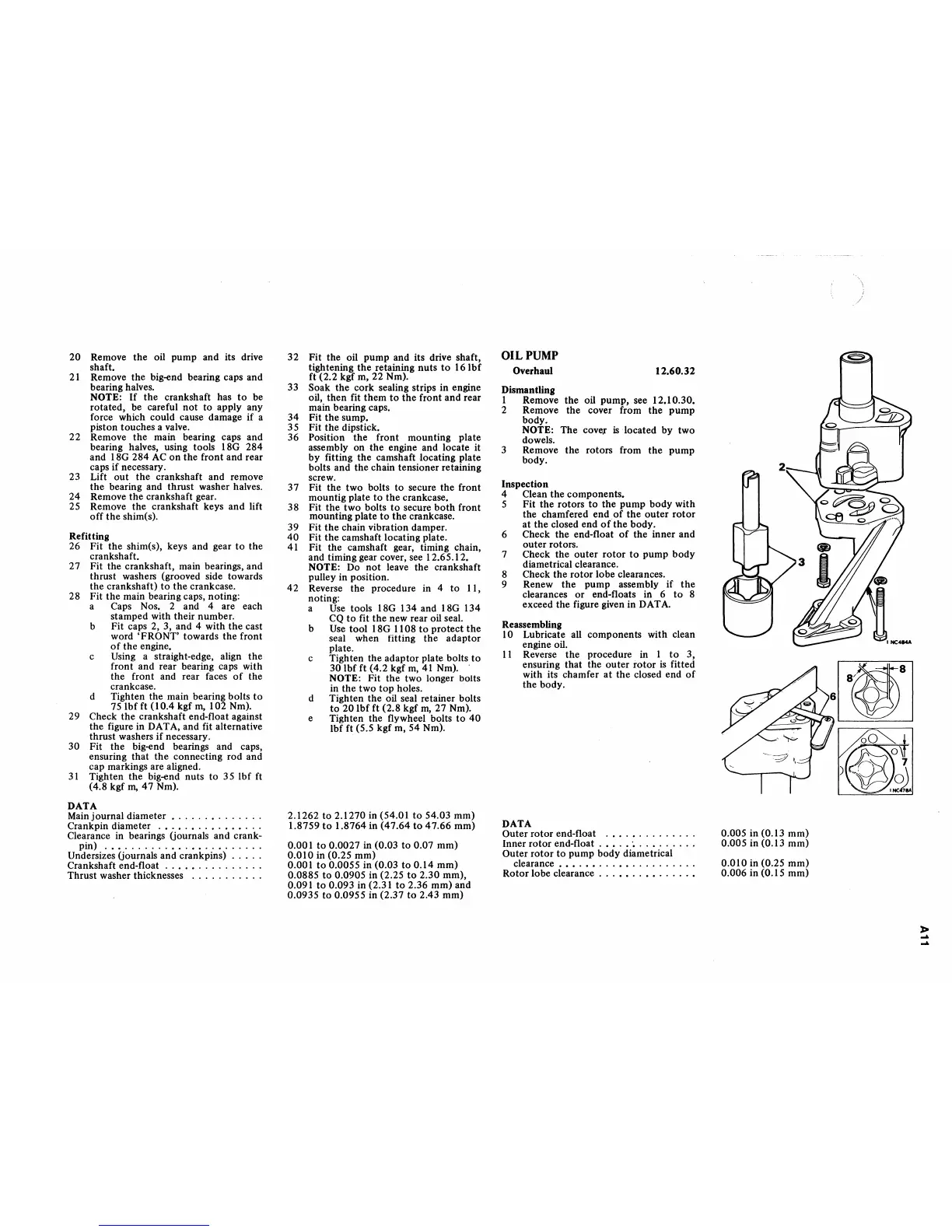

I Remove the oil pump, see 12.10.30.

2 Remove the cover from the pump

body.

NOTE: The

cove.r

is

located by two

dowels.

3 Remove the rotors from the pump

body.

Inspection

4 Clean the components.

5 Fit the rotors

to

the pump body with

the chamfered end

of

the

outer

rotor

at

the closed end

of

the body.

6 Check the end-float

of

the inner and

outer rotors.

7 Check the

outer

rotor

to

pump body

diametrical clearance.

8 Check the rotor lobe clearances.

9 Renew the pump assembly if

the

clearances

or

end-floats in 6

to

8

exceed the figure given in

OAT

A.

Reassembling

10 Lubricate all components with clean

engine oil.

II

Reverse

the

procedure in I

to

3,

ensuring that the

outer

rotor

is

fitted

with its chamfer

at

the closed end

of

the body.

DATA

Outer rotor end-float

.••.•.........

Inner rotor end-float

.••.•

~

..•......

Outer

rotor

to

pump body diametrical

clearance

•••.••...••..........

Rotor lobe clearance

...••..••.....•

~

'HC4MA

~lIIl

0.005 in (0.13 mm)

0.005 in (0.13 mm)

0.010 in (0.25 mm)

0.006 in {0.15

mm}

»

~

~

Loading...

Loading...