16

16

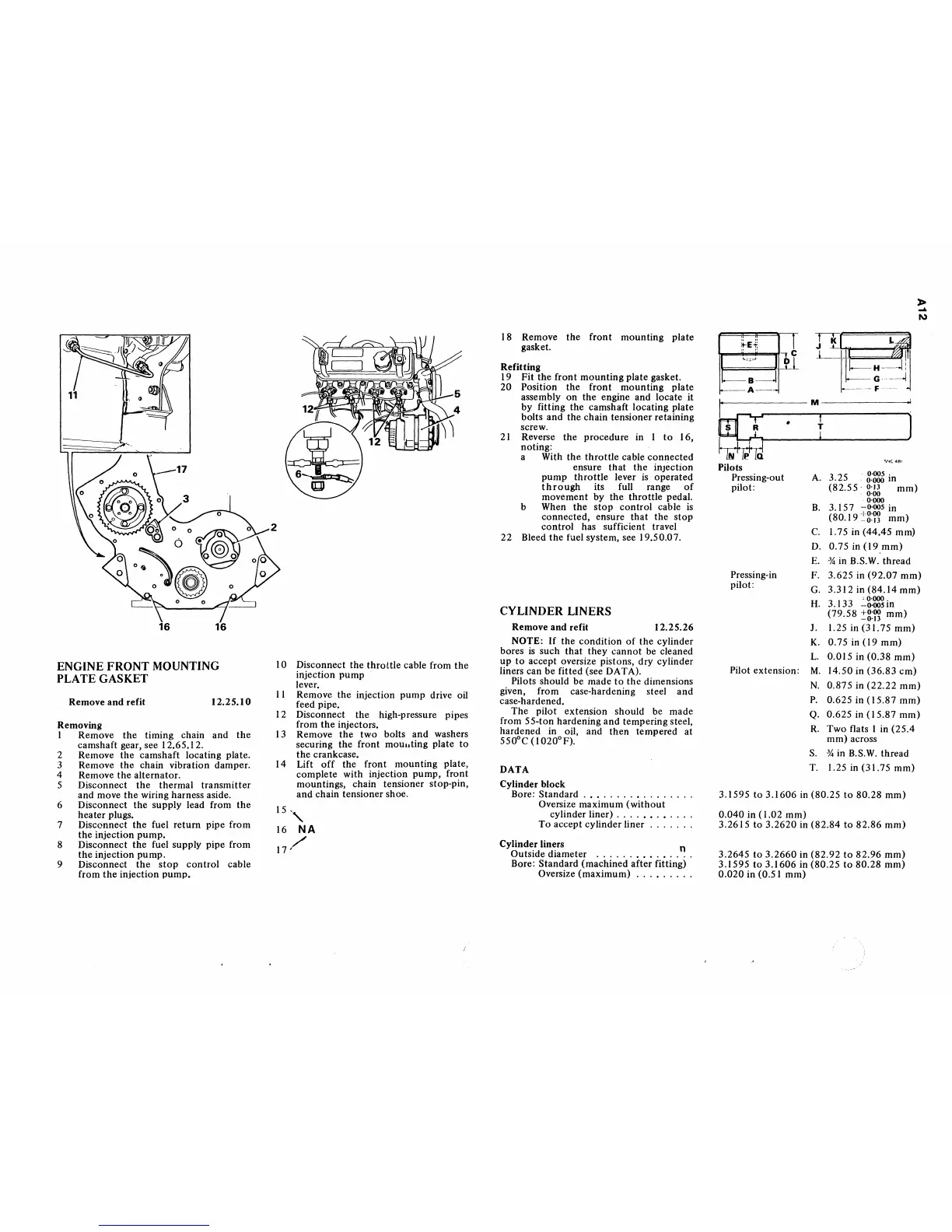

ENGINE

FRONT

MOUNTING

PLATE

GASKET

Remove

and

refit

12.25.10

Removing

I Remove

the

timing chain

and

the

camshaft gear, see 12.65.12.

2 Remove

the

camshaft locating plate.

3 Remove

the

chain vibration damper.

4 Remove

the

alternator.

5 Disconnect

the

thermal

transmitter

and

move

the

wiring harness aside.

6 Disconnect

the

supply

lead from

the

heater

plugs.

7 Disconnect

the

fuel

return

pipe from

the

injection

pump.

8 Disconnect

the

fuel supply pipe from

the

injection

pump.

9 Disconnect

the

stop

control

cable

from

the

injection

pump.

10 Disconnect

the

throttle

cable from

the

injection

pump

lever.

II

Remove the injection

pump

drive oil

feed pipe.

12 Disconnect

the

high-pressure pipes

from

the

injectors.

13 Remove

the

two

bolts

and

washers

securing the front moullting plate

to

the

crankcase.

14 Lift

off

the

front

mounting

plate,

complete

with injection

pump,

front

mountings, chain tensioner stop-pin,

and

chain tensioner shoe.

IS.,

16 NA

17'/

18 Remove

the

front

mounting

plate

gasket

Refitting

19

Fit

the

front

mounting

plate gasket.

20

Position

the

front

mounting

plate

assembly

on

the

engine

and

locate it

by

fitting

the

camshaft

locating

plate

bolts

and

the

chain

tensioner

retaining

screw.

21

Reverse

the

procedure

in I

to

16,

noting:

a With

the

throttle

cable

connected

ensure

that

the

injection

pump

throttle

lever

is

operated

through

its full range

of

movement

by

the

throttle

pedal.

b When

the

stop

control

cable

is

connected,

ensure

that

the

stop

control

has sufficient travel

22 Bleed

the

fuel system, see 19.50.07.

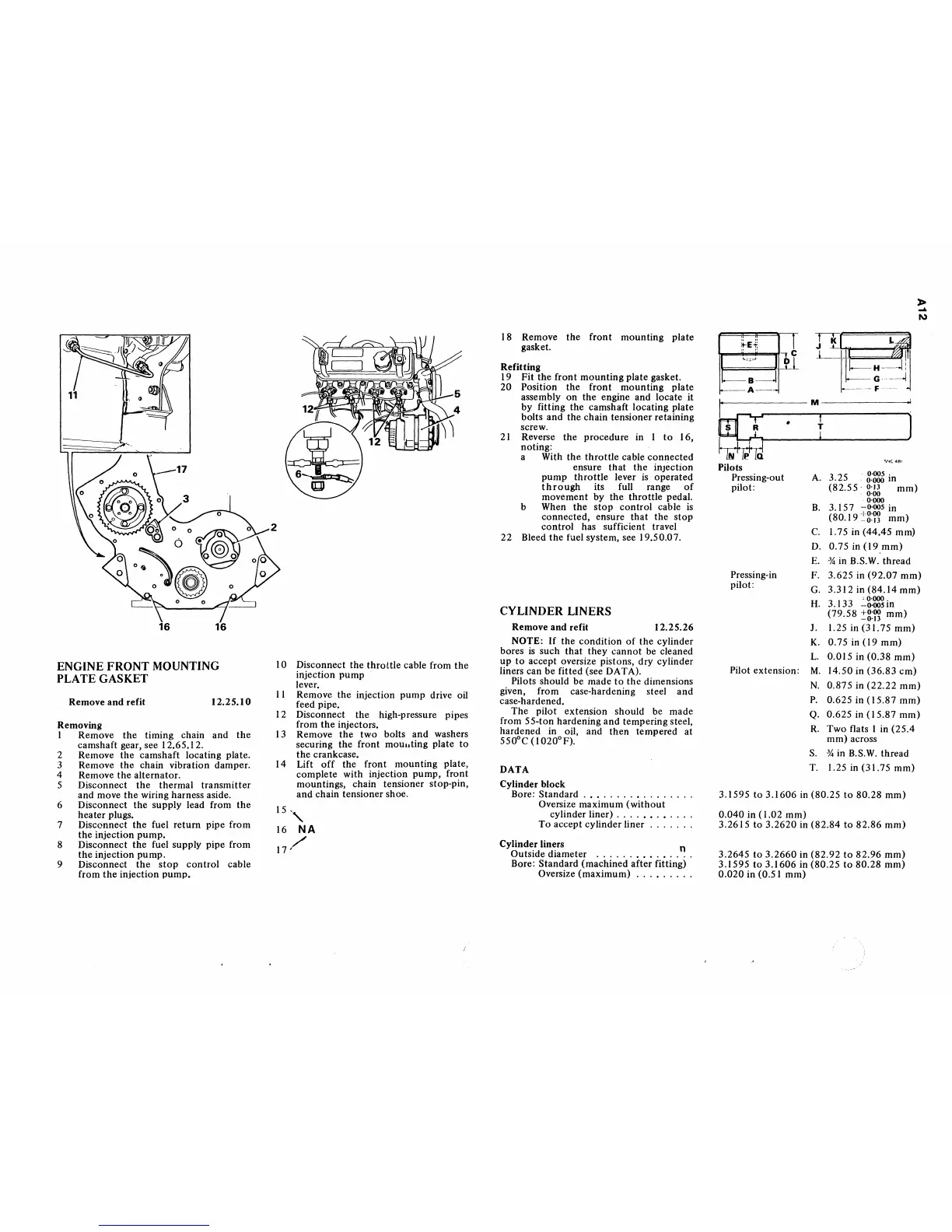

CYLINDER LINERS

Remove

and

refit

12.25.26

NOTE:

If

the

condition

of

the

cylinder

bores

is

such

that

they

cannot

be cleaned

up

to

accept oversize pistons, dry cylinder

liners can be fitted (see DATA).

Pilots should be made

to

the

dimensions

given, from case-hardening steel

and

case-hardened.

The

pilot extension should be

made

from

55-ton

hardening

and

tempering steel,

hardened

in oil,

and

then

tempered at

550°C

(l020°F).

DATA

Cylinder block

Bore:

Standard

.•...............

Oversize maximum

(without

cylinder liner)

.........

.

To

accept

cylinder

liner

Cylinder liners n

Outside

diameter

...........

.

Bore:

Standard

(machined

after

fitting)

Oversize

(maximum)

........

.

" M

~

· t 1

J\I

f>

Q

Pilots

Pressing-out

pilot:

"'~4ft'

A.

3.25

8:~

in

(82.55'

0·13

mm)

0'00

0'000

B.

3.

IS

7

-0'005

in

(80.19

:"g:r:

mm)

C.

1.75 in

(44.45

mm)

D.

0.75

in

(19

mm)

E.

34

in B.S.

W.

thread

»

....

I\)

Pressing-in

pilot:

F. 3.625 in

(92.07

mm)

G.3.312in(84.14mm)

Pilot extension:

, 0'000

H.

3.133

-0'005

in

(79.58

:::g:r:

mm)

J. 1.25 in

(31.75

mm)

K.0.75in(l9mm)

L.

0.015

in

(0.38

mm)

M.

14.50 in

(36.83

em)

N.

0.875

in

(22.22

mm)

P.

0.625 in

(15.87

mm)

Q.

0.625

in

(15.87

mm)

R.

Two

flats I in

(25.4

mm)

across

S.

34

in B.S.W.

thread

T. 1.25 in (31.75

mm)

3.1595

to

3.1606

in

(80.25

to

80.28

mm)

0.040

in (1.02

mm)

3.2615

to

3.2620

in

(82.84

to

82.86

mm)

3.2645

to

3.2660

in

(82.92

to

82.96

mm)

3.1595

to

3.1606

in

(80.25

to

80.28

mm)

0.020

in (0.51

mm)

Loading...

Loading...