CYLINDER HEAD

Overhaul

12.29.19

Service tools: 18G 27, 18G 29, 18G 45,

18G 167, 18G 167

A,

18G 167

B,

18G 167

C,

18G 174, 18G

1741\,

18G 174

B,

18G

174

C,

18G 174

D,

18G 284, 18G

284

P

I Remove the cylinder head gasket, see

12.29.02.

2 Remove the three remaining

heater

plugs from the cylinder head.

3 Remove

the

injectors, usinl: tools 18G

284, and 18G

284

P.

4 Remove

the

two sealing washers from

each injector position.

5 Remove

the

heater hose from

the

cylinder head

•..

6 Remove

the

manifolds and gasket.

7 Mark the combustion chamber iriserts

for refitting jn their original positions.

8 Remove

the

combustion

chamber

inserts,

if

necessary using a soft drift

through

the

injector holes.

9 Push

out

the

injector heat shields and

their

sealing washers.

10 Remove

the

water

outlet

elbow and its

gasket.

II

Lift

out

the

thermostat.

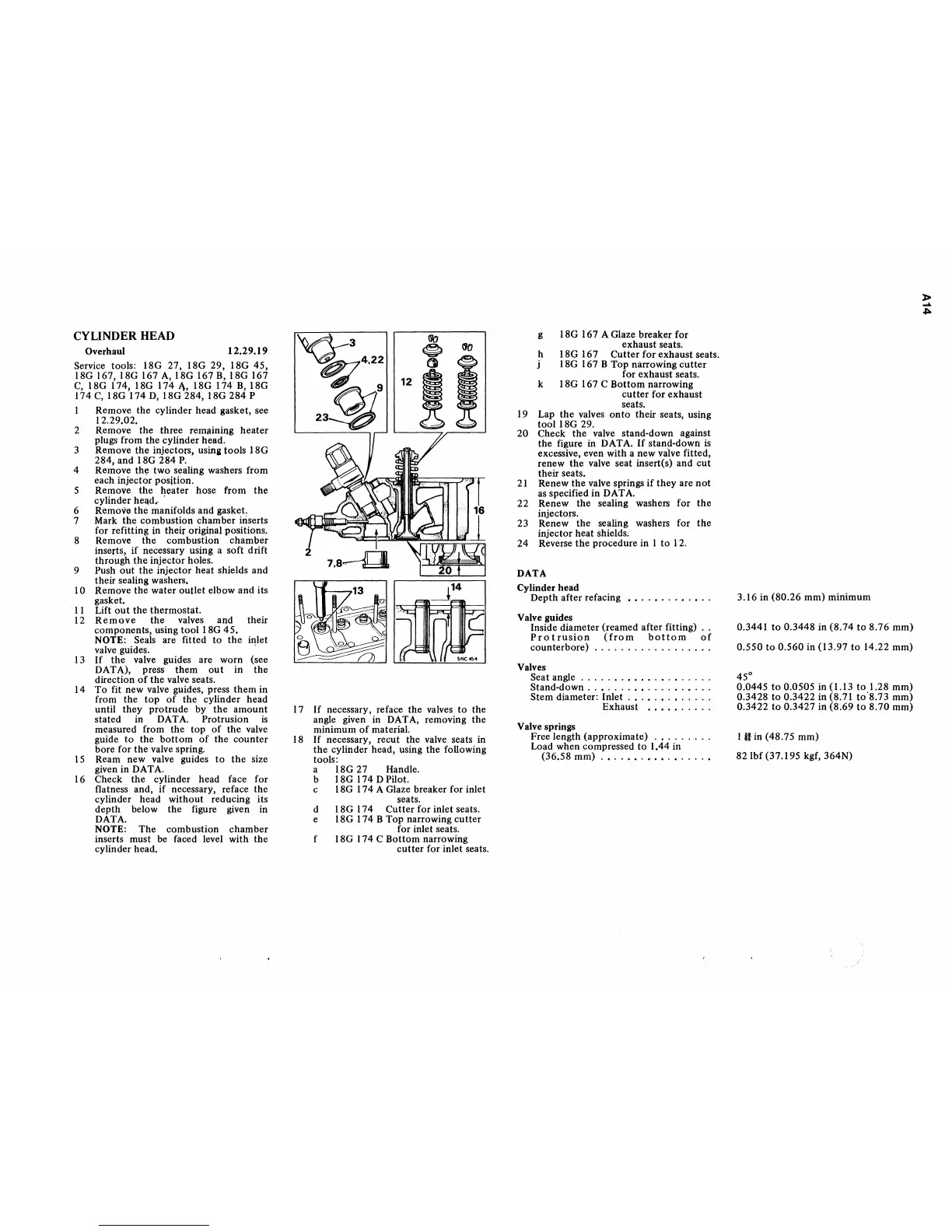

12

Remove

the

valves and their

components, using

tool

18G

45.

NOTE: Seals are fitted

to

the

inlet

valve guides.

-

13

If

the

valve guides are worn (see

DATA), press

them

out

in

the

direction

of

the

valve seats.

14

To

fit new valve guides, press

them

in

from

the

top

of

the

cylinder head

until they

protrude

by

the

amount

stated in DATA. Protrusion

is

measured from

the

top

of

the

valve

guide

to

the

bottom

of

the

counter

bore for

the

valve spring.

15

Ream new valve guides

to

the

size

given in DATA.

16 Check

the

cylinder head face for

flatness and, if necessary, reface

the

cylinder head without reducing its

depth

below

the

figure given in

DATA.

NOTE:

The

combustion

chamber

inserts must be faced level with

the

cylinder head

o

\'J{)

17

If

necessary, reface the valves

to

the

angle given in DATA, removing

the

minimum

of

material.

18

If

necessary, recut the valve seats in

the

cylinder head, using

the

following

tools:

a 18G 27 Handle.

b 18G 174 DPilot.

c 18G 174 A Glaze breaker for inlet

seats.

d 18G 174

Cutter

for inlet seats.

e 18G 174 B Top narrowing

cutter

for inlet seats.

18G 174 C

Bottom

narrowing

cutter

for inlet seats.

g 18G 167 A Glaze breaker for

exhaust seats.

h 18G 167

Cutter

for

exhaust seats.

18G 167 B

Top

narrowing

cutter

for exhaust seats.

k 18G 167 C

Bottom

narrowing

cutter

for exhaust

seats.

19 Lap

the

valves

onto

their seats, using

tool 18G 29.

20 Check

the

valve stand-down against

the

figure in DATA.

If

stand-down

is

excessive, even with a new

va1ve

fitted,

renew

the

valve seat insert(s) and

cut

their seats.

21

Renew

the

valve springs

if

they

are

not

as specified in DATA.

22

Renew

the

sealing washers

for

the

injectors.

23 Renew

the

sealing washers for

the

injector heat shields;

24

Reverse

the

procedure in I

to

12.

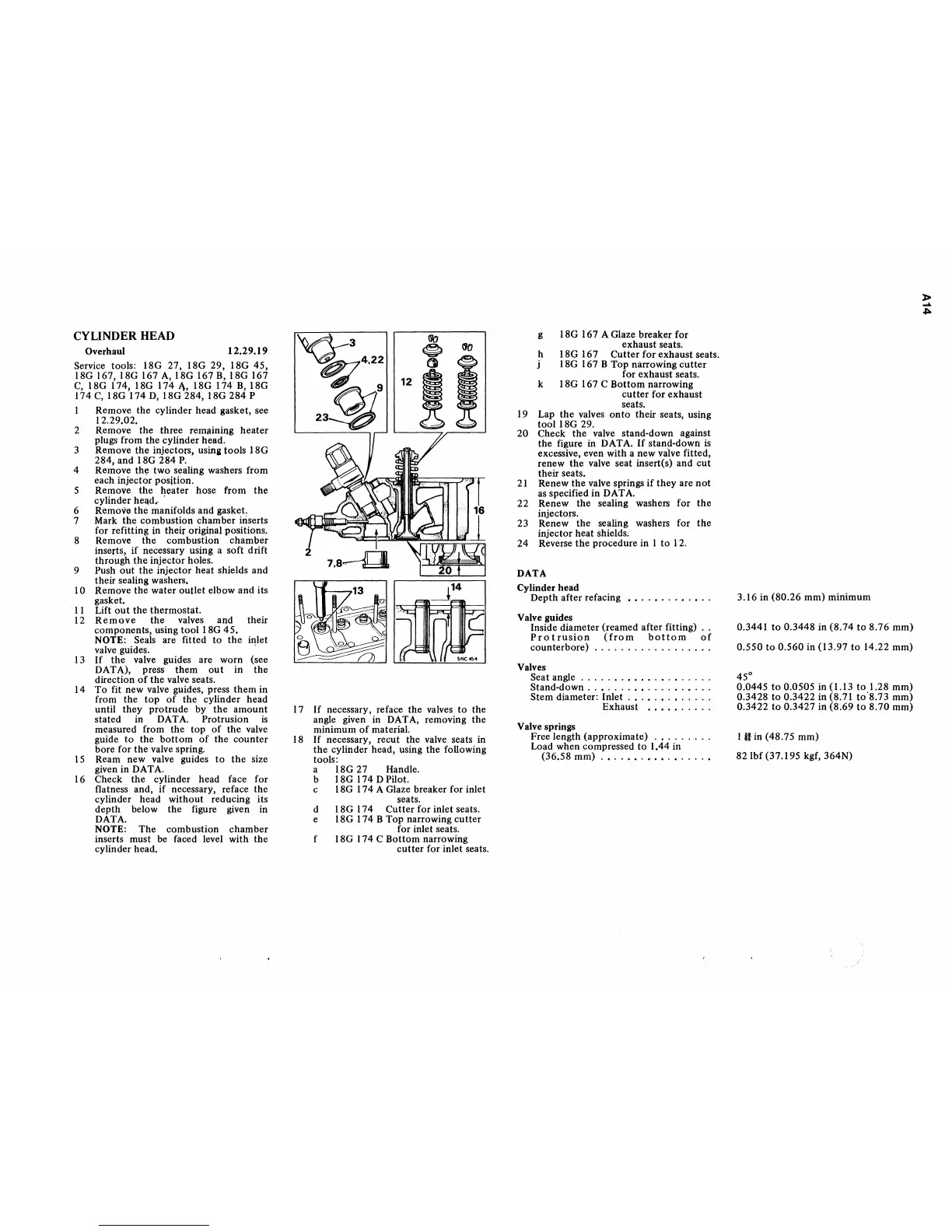

DATA

Cylinder

head

Depth

after

refacing

Valve guides

Inside diameter (reamed after fitting)

Protrusion

(from

bottom

of

counterbore)

.................

.

Valves

Seat angle

..............•.....

Stand-down

..•.....•......•...

Stem

diameter: Inlet

............

.

Exhaust

..•.......

Valve springs

Free length (approximate)

........

.

Load when compressed

to

1.44 in

(36.58 mm)

....••.•...•.....

3.16 in

(80.26

mm) minimum

0.3441

to

0.3448 in (8.74

to

8.76 mm)

0.550

to

0.560

in (13.97

to

14.22 mm)

45°

0.0445

to

0.0505 in (1.13

to

1.28 mm)

0.3428

to

0.3422

in (8.71

to'8.73

mm)

0.3422

to

0.3427 in

(8.69

to

8.70

mm)

I

it

in (48.75 mm)

82 Ibf (37.195 kgf,

364N)

~

....

~

Loading...

Loading...