VALVE CLEARANCE

Check and adjust 12.29.48

Checking

I Remove the rocker cover

ana

gasket.

2 Check, and

if

necessary adjust, the

clearance between the rocker arms and

valve stems against the figure in

DATA, working in the following

order:

Check:

No. I valve with

No.8

valve fully open.

3

" 6

" 5 4

2 7

" S " I

,,6

,,3

4 " 5

" 7 " 2

DATA

Valve rocker clearance (cold)

ROCKER

SHAFf

ASSEMBLY

Remove and refit

Service tool: ISG 694

Removing

I

NA

2 Drain the cooling system.

12.29.54

3 Remove the rocker cover and gasket.

4

Slacken evenly and remove the eight

nuts retaining

the

rocker shaft

brackets.

5 Remove the locking plate from

the

rocker shaft rear bracket.

6 Remove

the

rocker shaft assembly and

the

shim under each centre bracket.

4

2,

I

be...j

3

4HC104A

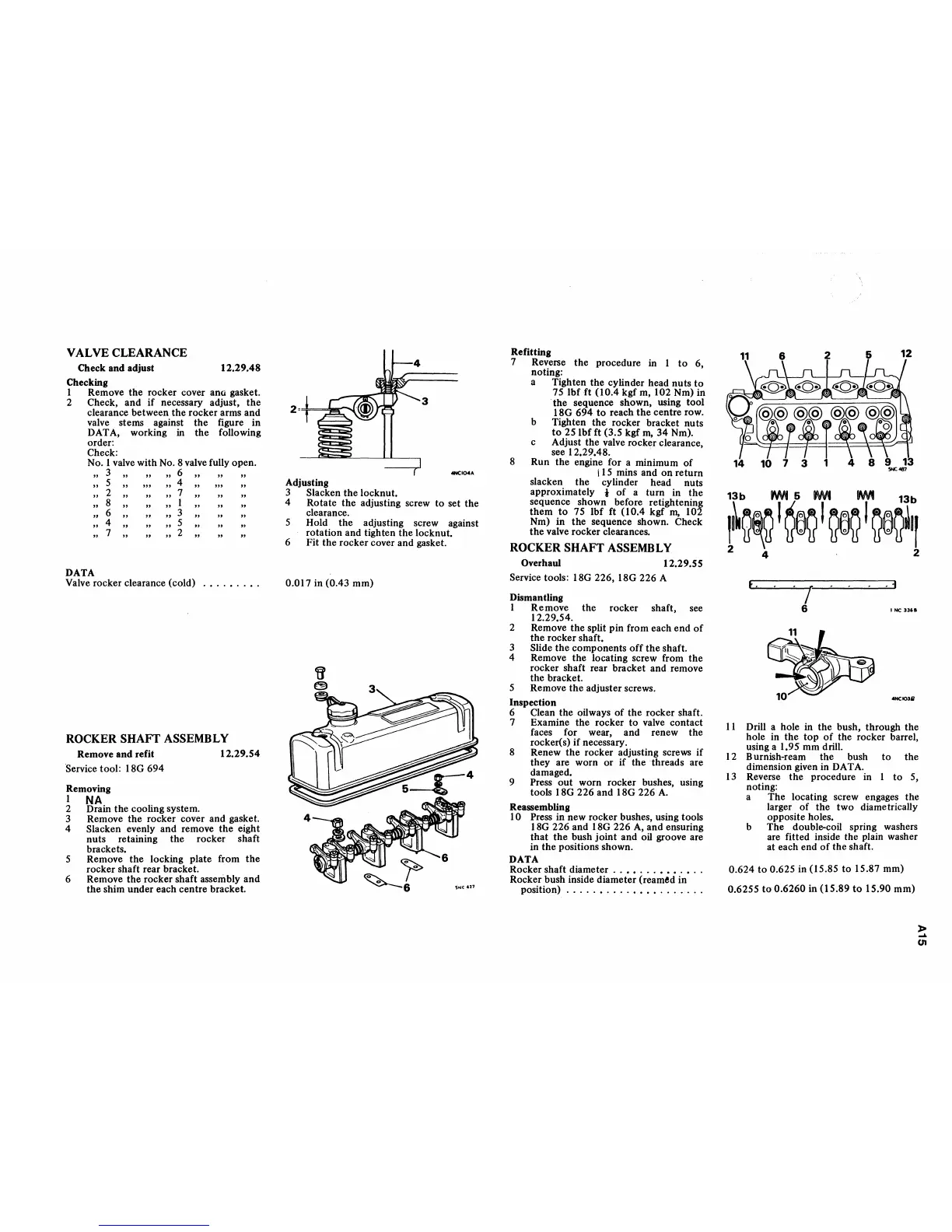

Adjusting

3

Slacken the locknut.

4 Rotate the adjusting screw

to

set the

clearance.

5 Hold the adjusting screw against

rotation and tighten the locknut.

6 Fit the rocker cover and gasket.

0.017 in (0.43 mm)

'SNC

.,7

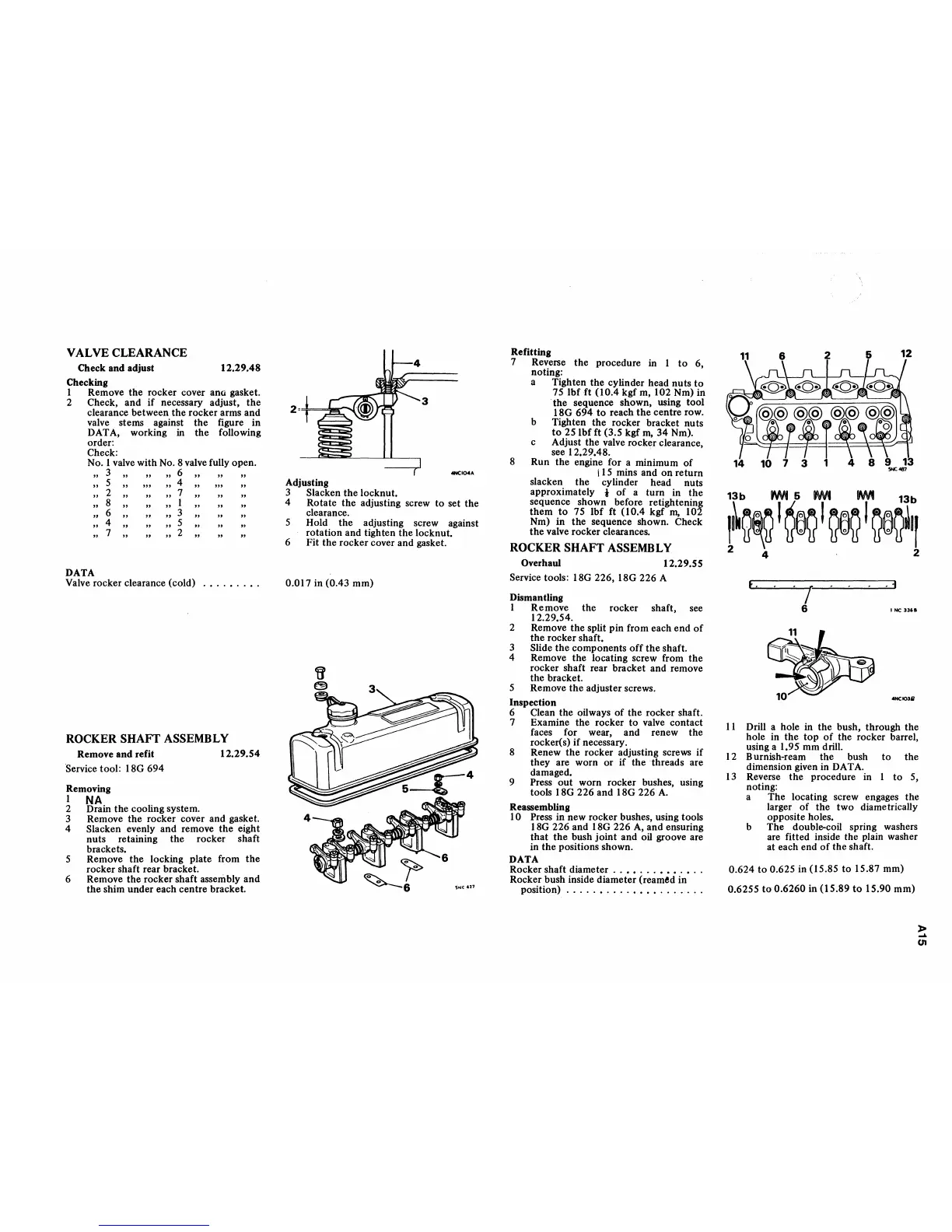

Refitting

7 Reverse

the

procedure in I

to

6,

noting:

a Tighten the cylinder head nuts

to

75

Ibfft

(10.4 kgf m, 102 Nm) in

. the sequence shown, using tool

ISG 694

to

reach

the

centre row.

b Tighten the rocker bracket nuts

to

251bf

ft (3.5 kgf

rn,

34

Nm).

c Adjust the valve rocker clearance,

see 12.29.4S.

S Run the engine for a minimum

of

115

mins and

on

return

slacken the cylinder head nuts

approximately

t

of

a turn in

the

sequence shown before retightening

them

to

75 Ibf ft (10.4 kgf

rn,

102

Nm)

in

the sequence shown. Check

the

valve rocker clearances.

ROCKER

SHAFf

ASSEMBLY

Overhaul 12.29.55

Service tools: ISG 226, ISG 226 A

Dismantling

I Remove the rocker shaft, see

12.29.54.

2 Remove the split pin from each

end

of

the rocker shaft.

3

Slide the components

off

the

shaft.

4 Remove the locating screw from

the

rocker shaft rear bracket and remove

the bracket.

5 Remove

the

adjuster screws.

Inspection

6 Clean the oilways

of

the rocker shaft.

7 Examine the rocker to valve contact

faces for wear, and renew the

rocker(s)

if

necessary.

S Renew

the

rocker adjusting screws

if

they are worn

or

if

the

threads

are

damaged.

9

Press

out

worn rocker bushes, using

tools

ISG 226 and ISG 226

A.

Reassembling

10 Press in new rocker bushes, using tools

ISG 226 and ISG 226

A,

and ensuring

that

the

bush

joint

and oil groove are

in

the

positions shown.

DATA

Rocker shaft diameter

..••...•••.•..

Rocker bush inside diameter (reamed in

position)

.....•....••••.......

6 12

13b

PM·

6

W\I1

MIt

13b

I~Q~

I

~Q

I

~

I

Q~Q.II

2 4 . 2

t.

_

.1

I

6 INC

....

_10311

II

Drill a hole in the bush, through the

hole in the

top

of

the rocker barrel,

using a 1.95 mm drill.

I 2 Burnish-ream the bush

to

the

dimension given in DATA.

13

Reverse

the

procedure in I

to

5,

noting:

a The locating screw engages the

larger

of

the two diametrically

opposite holes.

b The

doubl&ocoil

spring washers

are fitted inside the plain washer

at each end

of

the shaft.

0.624

to

0.625 in (15 .S5

to

15.S7 mm)

0.6255

to

0.6260 in

(l5.S9

to

15.90 mm)

»

...

U1

Loading...

Loading...