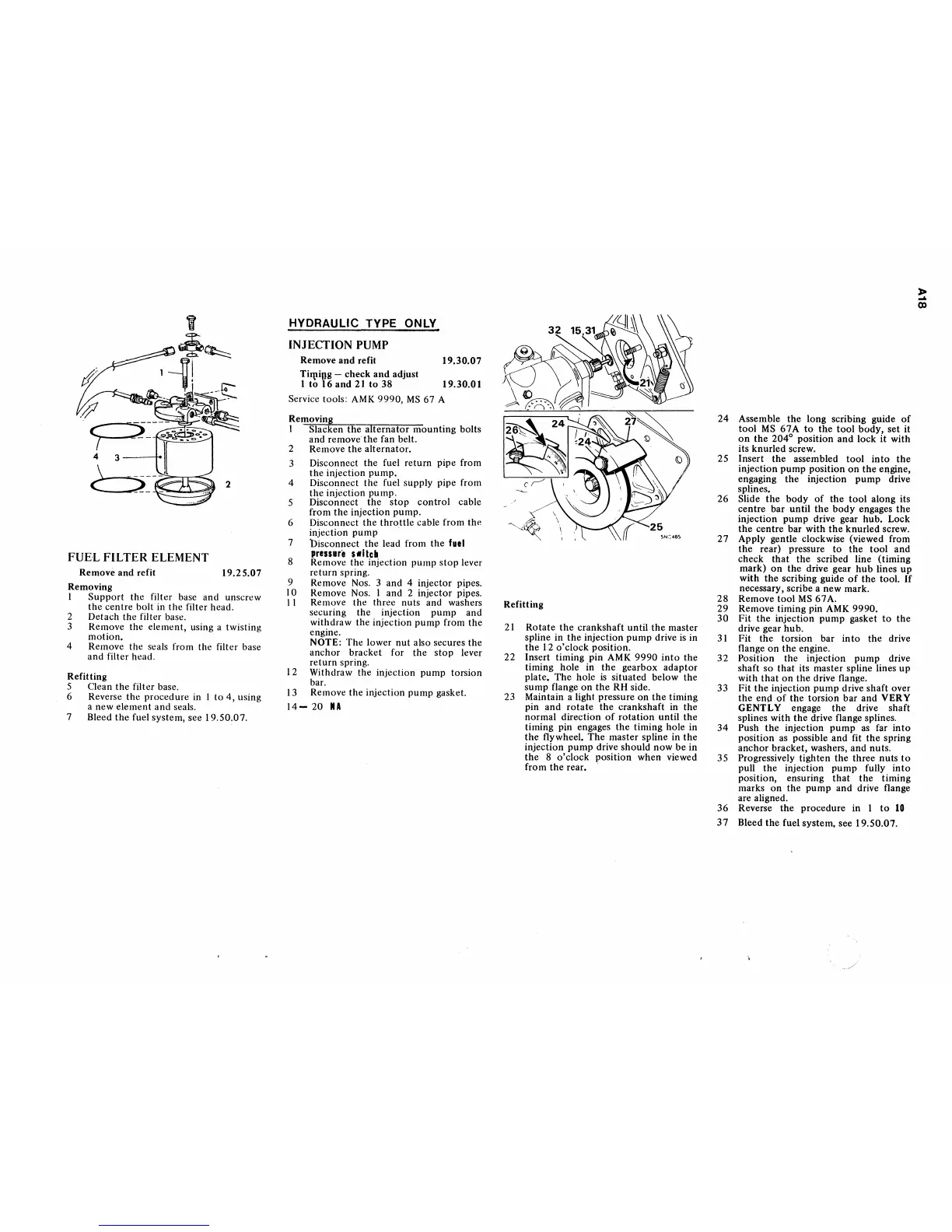

FUEL FILTER ELEMENT

Remove and refit

19.25.07

Removing

1

Support

the filter base and unscrew

the

centre bolt in

the

filter head.

2 Detach the filter base.

3 Remove the element, using a twisting

motion.

4 Remove the seals from the filter base

and

filter head.

Refitting

5 Clean the filter base.

6 Reverse the procedure in

I

to

4,

using

a new element and seals.

7 Bleed

the

fuel system, see 19.50:07.

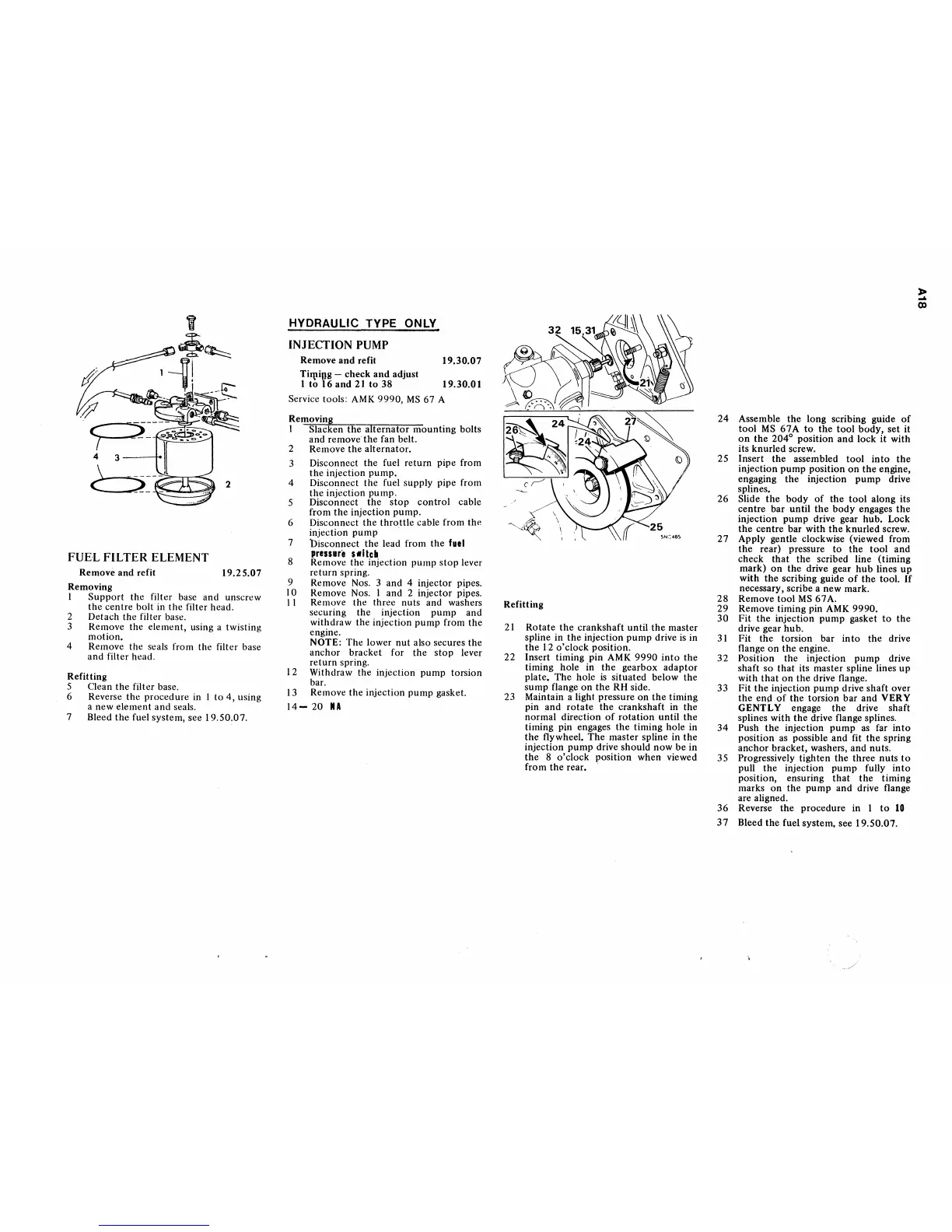

HYDRAULIC TYPE ONLY

INJECfION

PUMP

Remove

and

refit

Ti'lliUg -

check

and

adjust

1

to

16

and

21

to

38

19.30.07

19.30.01

Service tools:

AMK

9990,

MS

67 A

Removing

I Slacken

the

alternator

mounting

bolts

and

remove"the fan belt.

2 Remove

the

alternator.

3 Disconnect the fuel return pipe from

the

injection

pump.

4 Disconnect the fuel supply pipe from

the

injection pump.

5 Disconnect

the

stop

control

cable

from

the

injection

pump.

6 Disconnect

the

throttle

cable from

the

injection

pump

"

7 l>isconnect

the

lead from

the

fuel

preSSIre

ulte.

8 Remove the injection

pump

stop

lever

return spring.

9 Remove Nos. 3

and

4 injector pipes.

10 Remove Nos. I

and

2 injector pipes.

II

Remove the three nuts and washers

securing the injection

pump

and

withdraw the injection

pump

from

the

engine.

NOTE:

The

lower

nut

also secures the

anchor

bracket for

the

stop

lever

return

spring.

12 Withdraw the injection

pump

torsion

bar.

13

Remove the injection

pump

gasket.

14-

20

IIA

~~

SN::46S

Refitting

21

Rotate

the

crankshaft until

the

master

spline in

the

injection

pump

drive

is

in

the

12

o'clock

position.

22 Insert timing pin AMK

9990

into

the

timing hole in

the

gearbox

adaptor

plate.

The

hole

is

situated below

the

sump

flange

on

the

RH side.

23 Maintain a light pressure

on

the

timing

pin

and

rotate

the

crankshaft in the

normal direction

of

rotation

until

the

timing pin engages

the

timing hole in

the

flywheel.

The

master spline in

the

injection

pump

drive should

now

be

in

the

8

o'clock

position when viewed

from

the rear. "

24

Assemble

the

long

scribing guide

of

tool

MS

67A

to

the

tool

body,

set

it

on

the

204

0

position

and

lock

it

with

its knurled screw.

25 Insert the assembled

tool

into

the

injection

pump

position

on

the

engine,

engaging

the

injection

pump

drive

splines.

26

Slide

the

body

of

the

tool

along its

centre

bar

until

the

body

engages

the

injection

pump

drive gear hub. Lock

the

centre

bar

with

the

knurled screw.

27

Apply gentle clockwise (viewed from

the

rear) pressure

to

the

tool

and

check

that

the

scribed line (timing

mark)

on

the

drive gear

hub

lines

up

with

the

scribing guide

of

the

tool.

If

necessary, scribe a new mark.

28

Remove

tool

MS

67A.

29

Remove timing pin

AMK

9990.

30

Fit

the

injection

pump

gasket

to

the

drive gear hub.

31

Fit

the

torsion bar in

to

the drive

flange

on

the

engine.

32

Position the injection

pump

drive

shaft

so

that

its master spline lines

up

with

that

on

the

drive flange.

33

Fit

the

injection

pump

drive shaft over

the

end

of

the torsion

bar

and VERY

GENTLY

engage

the

drive shaft

splines with

the

drive flange splines.

34

Push

the

injection

pump

as

far

into

position

as

possible

and

fit

the

spring

anchor

bracket, washers, and nuts.

35 Progressively tighten the three

nuts

to

pull

the

injection

pump

fully

into

position, ensuring

that

the

timing

marks

on

the

pump

and

drive flange

are aligned.

36

Reverse

the

procedure in I

to

10

37

Bleed

the

fuel system, see 19.50.07.

,..

....

00

Loading...

Loading...