o

~~

~f?11

1--\.

~;;~

-I

},

39

29

/

!.~

.

.;;:~

C

30

SHe

"56

A

1 2

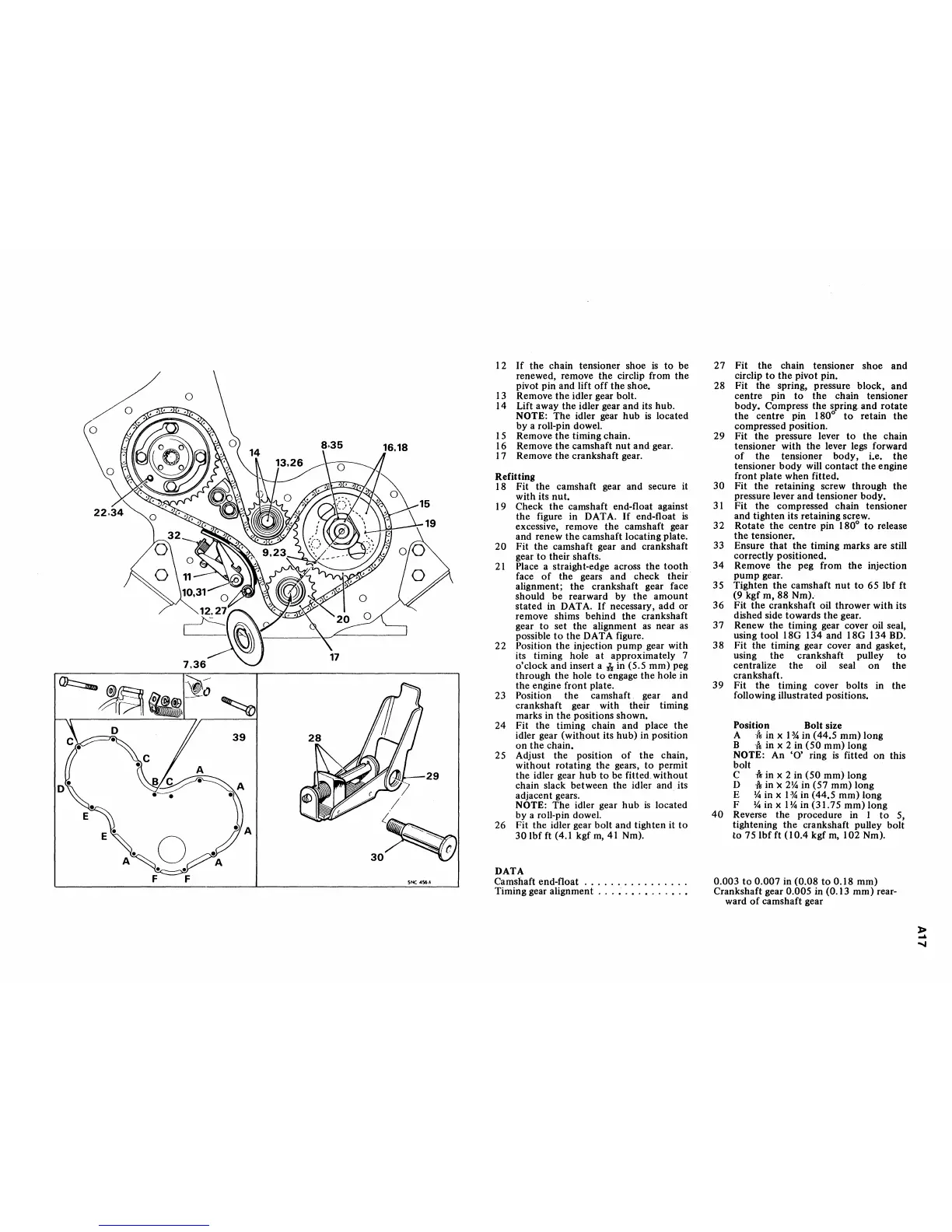

If

the chain tensioner shoe is to be

renewed, remove the circlip from the

pivot pin and lift

off

the shoe.

13

Remove the idler gear bolt.

14 Lift away the idler gear and its hub.

NOTE: The idler gear hub

is

located

by a roll-pin dowel.

15

Remove the timing chain.

16 Remove the camshaft

nut

and·gear.

17 Remove the crankshaft gear.

Refitting

18 Fit the camshaft gear and secure it

with its nut.

I 9 Check the camshaft end-float against

the figure in DATA.

If

end-float

is

excessive, remove

the

camshaft gear

and renew

the

camshaft locating plate.

20 Fit the camshaft gear and crankshaft

gear

to

their shafts.

21

Place a straight-edge across the

tooth

face

of

the gears and check their'

alignment; the crankshaft gear face

should be rearward by the amount

stated in DATA.

If

necessary, add or

remove shims behind the crankshaft

gear to set the alignment

as

near as

possible

to

the DATA figure.

22 Position the injection pump gear with

its timing hole

at

approximately 7

o'clock and insert a

* in (5.5 mm) peg

through the hole

to

engage the hole in

the engine front plate.

23 Position the camshaft gear and

crankshaft gear with their timing

marks in the positions shown.

24 Fit the timing chain and place the

idler gear (without its hub) in position

on

the chain.

25 Adjust the position

of

the chain,

without rotating the gears, to permit

the idler gear hub

to

be fitted. without

chain slack between the idler and its

adjacent gears.

NOTE: The idler gear hub

is

located

by a roll-pin dowel.

26 Fit the idler gear bolt and tighten it

to

30

lbf

ft (4.1 kgf

m,

41

Nm).

DATA

Camshaft end-float . . . . . . . . . . . . . . . .

Timing gear alignment

...•.•.•...•.•

27 Fit the chain tensioner shoe and

circlip

to

the pivot pin.

28 Fit the spring, pressure block, and

centre pin

to

the chain tensioner

body. Compress the

~ringand

rotate

the

centre pin 180

to

retain the

compressed position.

29 Fit the pressure lever

to

the chain

tensioner with the lever

legs

forward

of

the tensioner body, i.e.

the

tensioner body will contact the engine

front plate when fitted.

30 Fit the retaining screw through the

pressure lever and tensioner body.

31

Fit the compressed chain tensioner

and tighten its retaining screw.

32 Rotate the centre pin

180

0

to

release

the tensioner.

33 Ensure that the timing marks are still

correctly positioned.

34 Remove the peg from the injection

pump gear.

35 Tighten

the

camshaft

nut

to

65 Ibf

ft

(9 kgf m, 88 Nm).

36 Fit the crankshaft oil thrower with its

dished side towards the gear.

37 Renew the timing gear cover oil seal,

using tool 18G 134 and 18G 134

BD.

38 Fit the timing gear cover and gasket,

using the crankshaft pulley

to

centralize the oil seal

on

the

crankshaft.

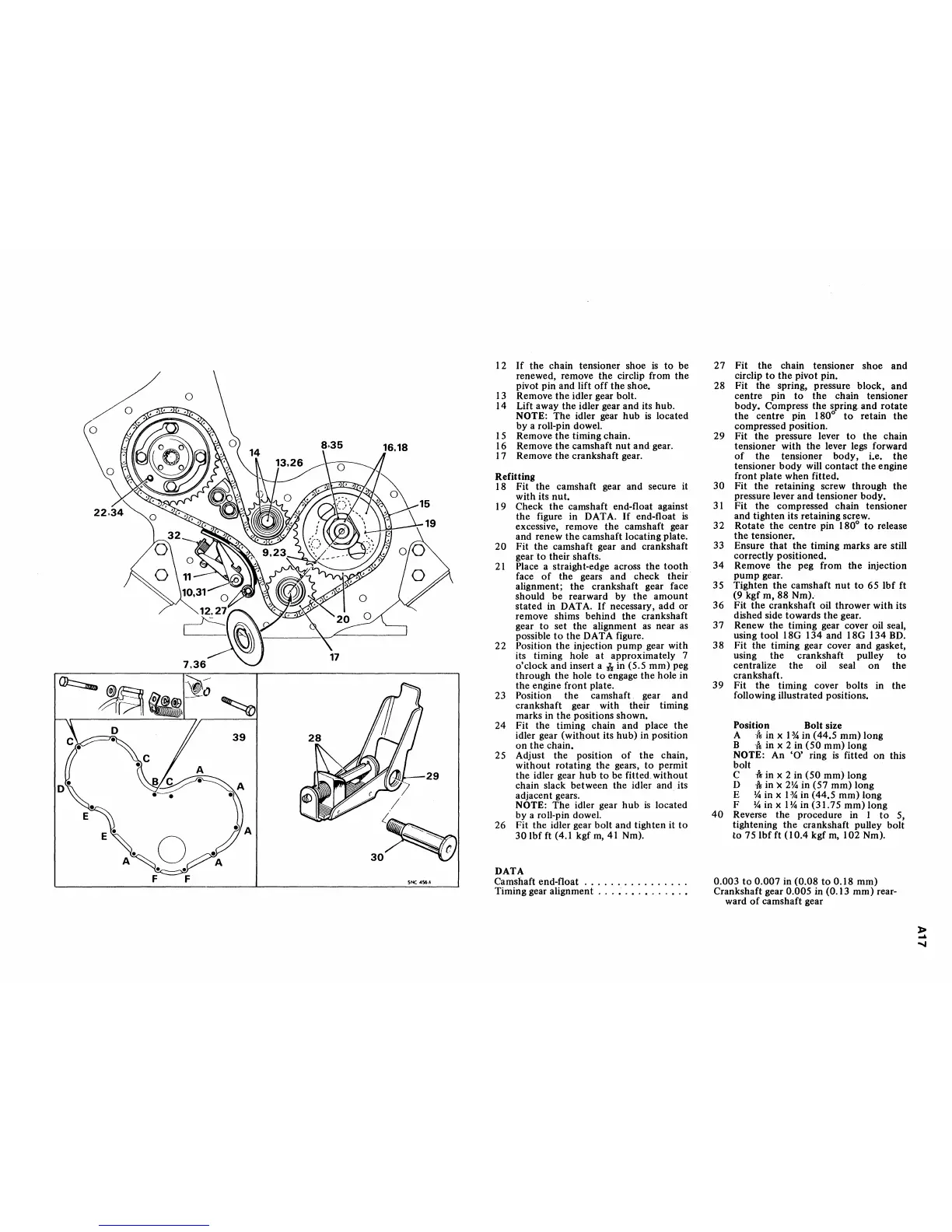

39 Fit the timing cover bolts in the

following illustrated positions.

Position Bolt size

A

·rw

in x I * in (44.5 mm) long

B

-A.

in x 2 in

(50

mm) long

NOTE: An

'0'

ring

is

fitted on this

bolt

C

*in

x 2 in (50 mm) long

D

* in

)(

2U.

in (57 mm) long

E

U.

in x I * in (44.5 mm) long

F

U.inxlU.in(31.75mm)long

40

Reverse the procedure in I

to

5,

tightening the

crankshaft pulley bolt

to

75lbf

ft (10.4 kgf

m,

102 Nm).

0.003

to

0.007 in (0.08 to 0.18 mm)

Crankshaft gear

0.005 in (0.13 mm) rear-

ward

of

camshaft gear

»

....

.....

Loading...

Loading...