BORG

WARNER

VELVET

DRIVE

TRANSMISSION

OPTIONAL

TRANSMISSION

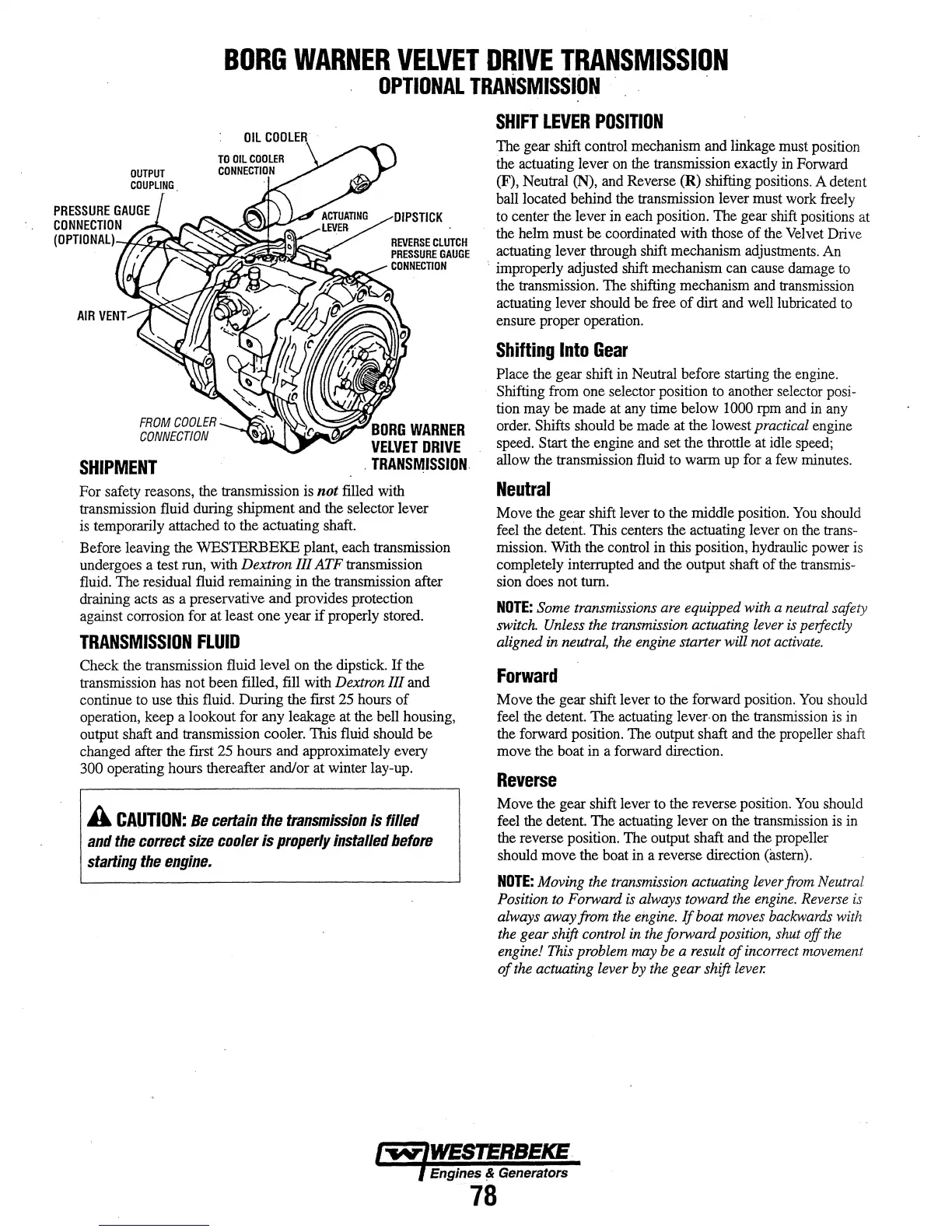

FROM

COOLER

CONNECTION

SHIPMENT

BORG

WARNER

VELVET

DRIVE

.

TRANSMISSION

For safety reasons, the transmission is not filled with

transmission fluid during shipment and the selector lever

is temporarily attached to the actuating shaft.

Before leaving the

WES1ERBEKE

plant, each transmission

undergoes a test run, with

Dextran III ATF transmission

fluid. The residual fluid remaining in the transmission after

draining acts

as

a preservative and provides protection

against corrosion for at least one year

if

properly stored.

TRANSMISSION

FLUID

Check the transmission fluid level on the dipstick.

If

the

transmission has not been filled, fill with

Dextran III and

continue

to

use this fluid. During the first 25 hours

of

operation, keep a lookout for any leakage at the bell housing,

output shaft and transmission cooler. This fluid should

be

changed after the first 25 hours and approximately every

300 operating hours thereafter and/or at winter lay-up.

A

CAUTION:

Be

certain

the

transmission

is

filled

and

the

correct

size

cooler

is

properly

installed

before

starting

the

engine.

SHIFT

LEVER

POSITION

The gear shift control mechanism and linkage must position

the actuating lever on the transmission exactly in Forward

(F), Neutral (N), and Reverse (R) shifting positions. A detent

ball located behind the transmission lever must work freely

to center the lever in each position. The gear shift positions at

the helm must be coordinated with those

of

the Velvet Drive

actuating lever through shift mechanism adjustments. An

• improperly adjusted shift mechanism can cause damage

to

the transmission. The shifting mechanism and transmission

actuating lever should be free

of

dirt and well lubricated to

ensure proper operation.

Shifting

Into

Gear

Place the gear shift in Neutral before starting the engine.

Shifting from one selector position to another selector posi-

tion may

be

made at any time below 1000 rpm and in any

order. Shifts should be made at the lowest

practical engine

speed. Start the engine and set the throttle at idle speed;

allow the transmission fluid to warm up for a

few

minutes .

Neutral

Move the gear shift lever to the middle position.

You

should

feel the detent. This centers the actuating lever on the trans-

mission. With the control in this position, hydraulic power

is

completely interrupted and the output shaft

of

the transmis-

sion does not tum.

NOTE:

Some transmissions

are

equipped with a neutral safety

switch.

Unless

the

transmission actuating lever

is

peifectly

aligned

in

neutral,

the

engine starter will not

activate.

Forward

Move the gear shift lever

to

the forward position.

You

should

feel the detent. The actuating lever-on the transmission is in

the forward position. The output shaft and the propeller shaft

move the boat in a forward direction.

Reverse

Move the gear shift lever to the reverse position.

You

should

feel the detent.

The

actuating lever on the transmission is in

the reverse position. The output shaft and the propeller

should move the boat in a reverse direction (astern).

NOTE:

Moving

the

transmission actuating lever

from

Neutral

Position

to

Forward

is

always toward

the

engine.

Reverse

is

always away from

the

engine.

If

boat moves

backwards

with

the

gear shift control

in

the

forward position, shut off

the

engine!

This

problem

may

be a result

of

incorrect movement

of

the

actuating lever

by

the

gear shift

lever.

Engines & Generators

78

Loading...

Loading...