OPERATION

The Gusher 10 ensures efficient throughput with an easy

pumping action. Full even strokes will obtain the best results.

The detachable handle is fitted with a lanyard and should be

safely secured close to the pump.

Gusher 10 output at 1m Lift and 0.5m Head

Fig 3: Performance table

Performance data is based on factory tests and is typical of

what may reasonably be achieved. Actual performance may

vary depending on installation and operating conditions.

MAINTENANCE

Inspection:

Regular inspection of the pump is recommended. Rubber

components should be replaced if worn or every three years

regardless of condition.

Replacement components and service kits (AK3706 for

Neoprene (clean bilge water) and AK3714 for Nitrile (oily bilge

water) are available from your local chandlery. It is

recommended a service kit is kept on board.

Winterising

At the end of the season, drain all water in the pipework and

pump chamber.

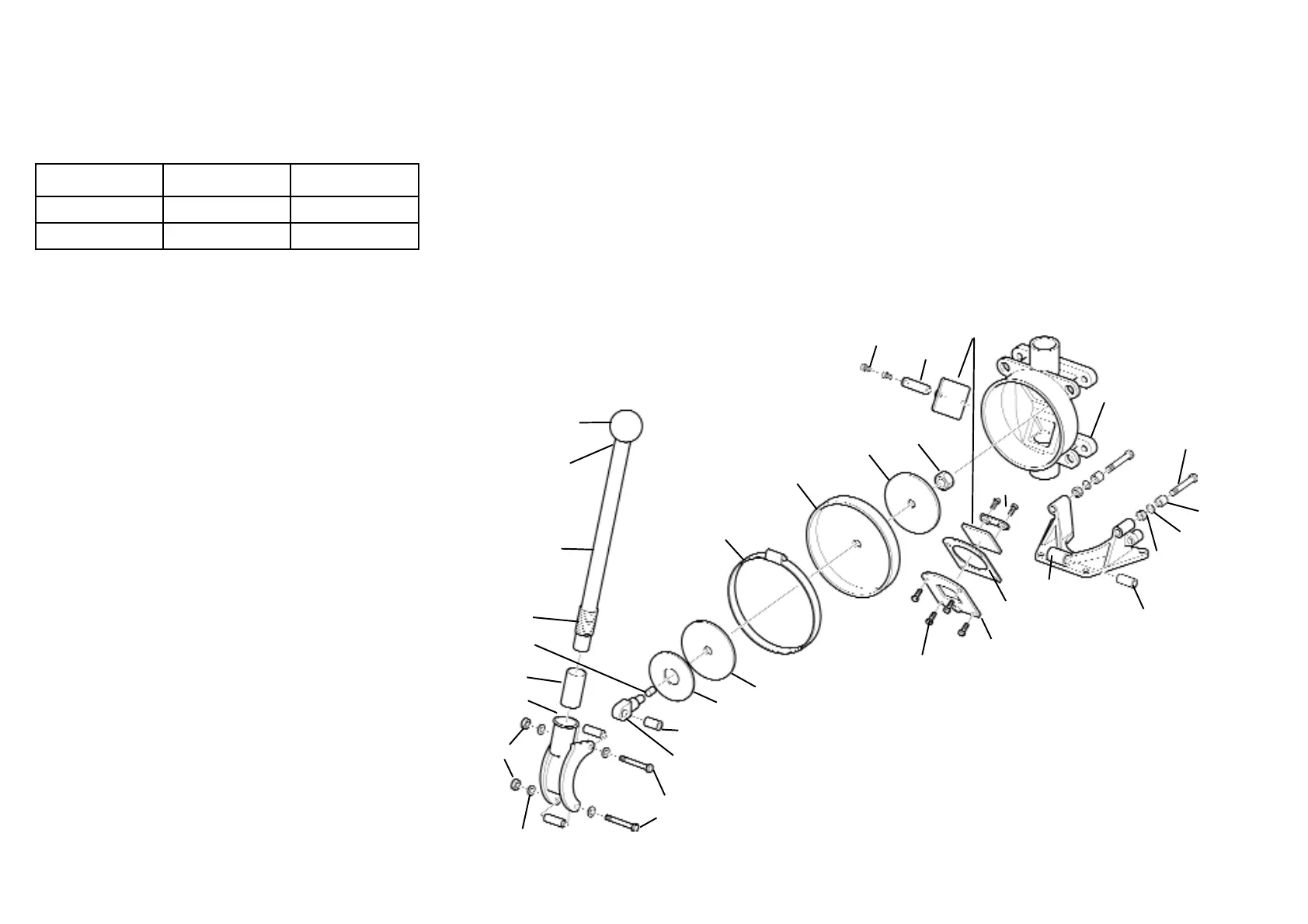

Changing the Diaphragm and Valves

1. Slacken and remove the wormdrive clip to release the

diaphragm

2. Release diaphragm nut and remove diaphragm plates and

diaphragm

3. Replace old inlet and outlet valves. Note: both inlet and

outlet valves are same shape. The service kits contain two

sets of valves - round ones for the MK 2 pump and square

valves for the MK 3 pump. DO NOT mix the valve types!

4. Replace diaphragm and tighten wormclip in position and

test for correct priming and discharge

WARRANTY

Whale Pumps are guarenteed for 5 years (1 year on

rubber parts) from date of purchase against defects in

materials and workmanship. If the unit proves faulty

return it to your supplier with proof of purchase and

purchase date.

The manufacturer retains the right to repair or replace

the unit.

The manufacturer cannot be held responsible for

claims arising from the incorrect installation,

unauthorisd modification or misuse of the product.

The above does not affect your satutory rights.

Old Belfast Road Bangor, Co. Down, N. Ireland, BT19 1LT

Tel: 02891 270531 Fax: 02891 466421 info@whalepumps.com

Body

Whale and Gusher are registered

marks of:

Munster Simms Engineering Ltd

Ouput At 60 strokes/min At 70 strokes/min

Gallons/min 16 20

Litres/min 74 71

ACCESSORIES

DP3804 - Alloy deck plate with lid

DP8903 - Plastic deck plate

AK3706 - Neoprene Spares Kit

AK3714 - Nitrile Spares Kit

SF5425 – Skinfitting

SB5865 – Top entry strainer

SB4222 – Side entry strainer

DV5606 – 2 way diverter valve

EB3488 – 90° elbow (male to female)

LV1215 – In line non return valve

HELPFUL HINTS

Pump fails to prime or chokes:

1. Check inlet hose connection is airtight, free from

blockages and does not collaspe during suction stroke

2. Inspect diaphragms - replace if damaged

3. Solid objects in the body of the pump may not prevent its

operation but should be removed to prevent damage

4. Inspect inlet and outlet valves for blockages. Clear with

finger or screwdriver and test.

Handle knob

Tolerance ring

Washer

Eye Bolt

Handle Tube

Lanyard

Buffer

Fork

Locknut

Washer

Bolt

Fulcrum brush and sleeve

Label

Clamping plate

Worm Drive Clip

Diaphragm

Nut

Bridge

piece

Screw

Bolt M6

Valve

Securing brush

Nut

Screw

Valve plate

Gasket

Bracket

Fork liner

Clamping plate

Fulcrum brush and sleeve

Ref No: sr_180.07_0313

Loading...

Loading...