PAGE 7

FOR SERVICE TECHNICIAN’S USE ONLY

DO NOT REMOVE OR DESTROY

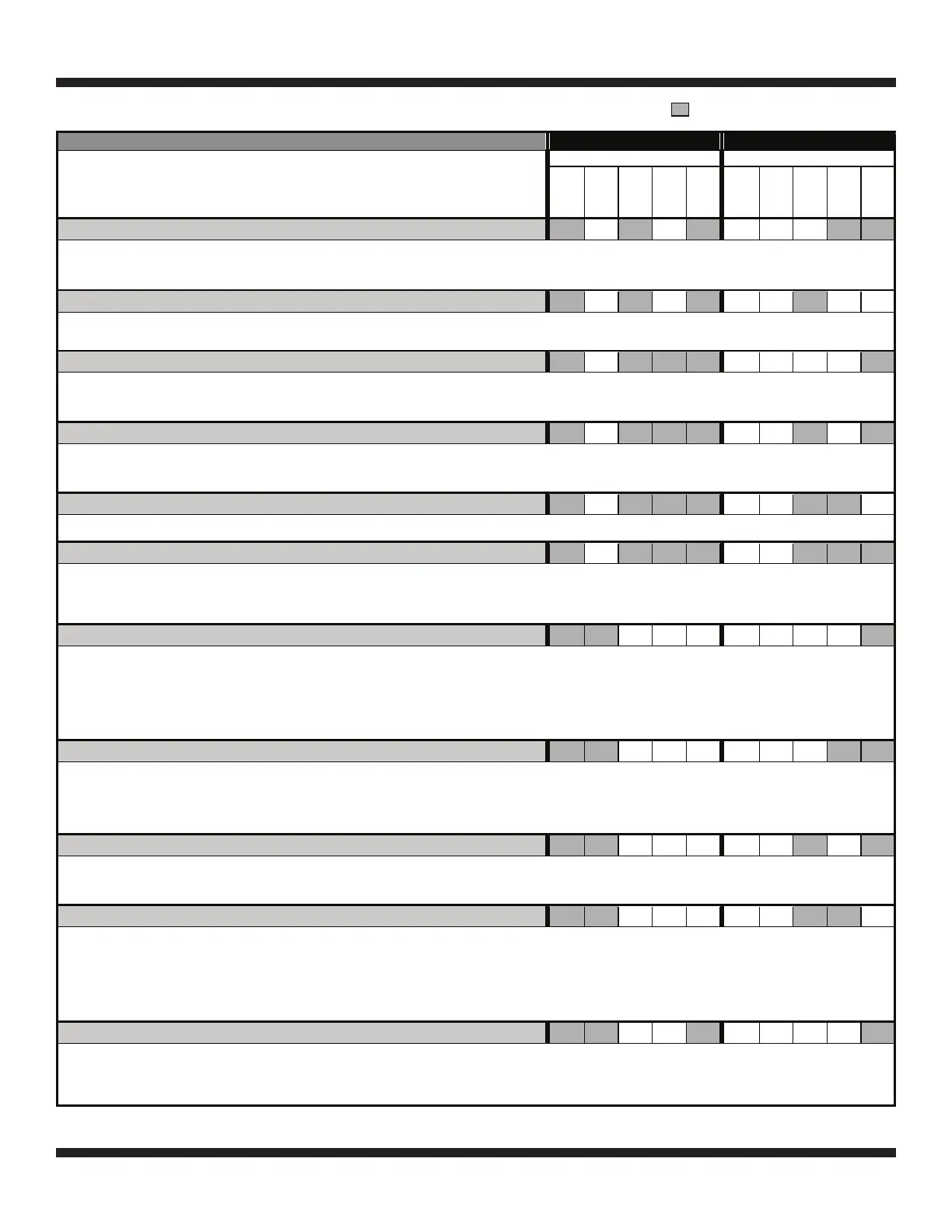

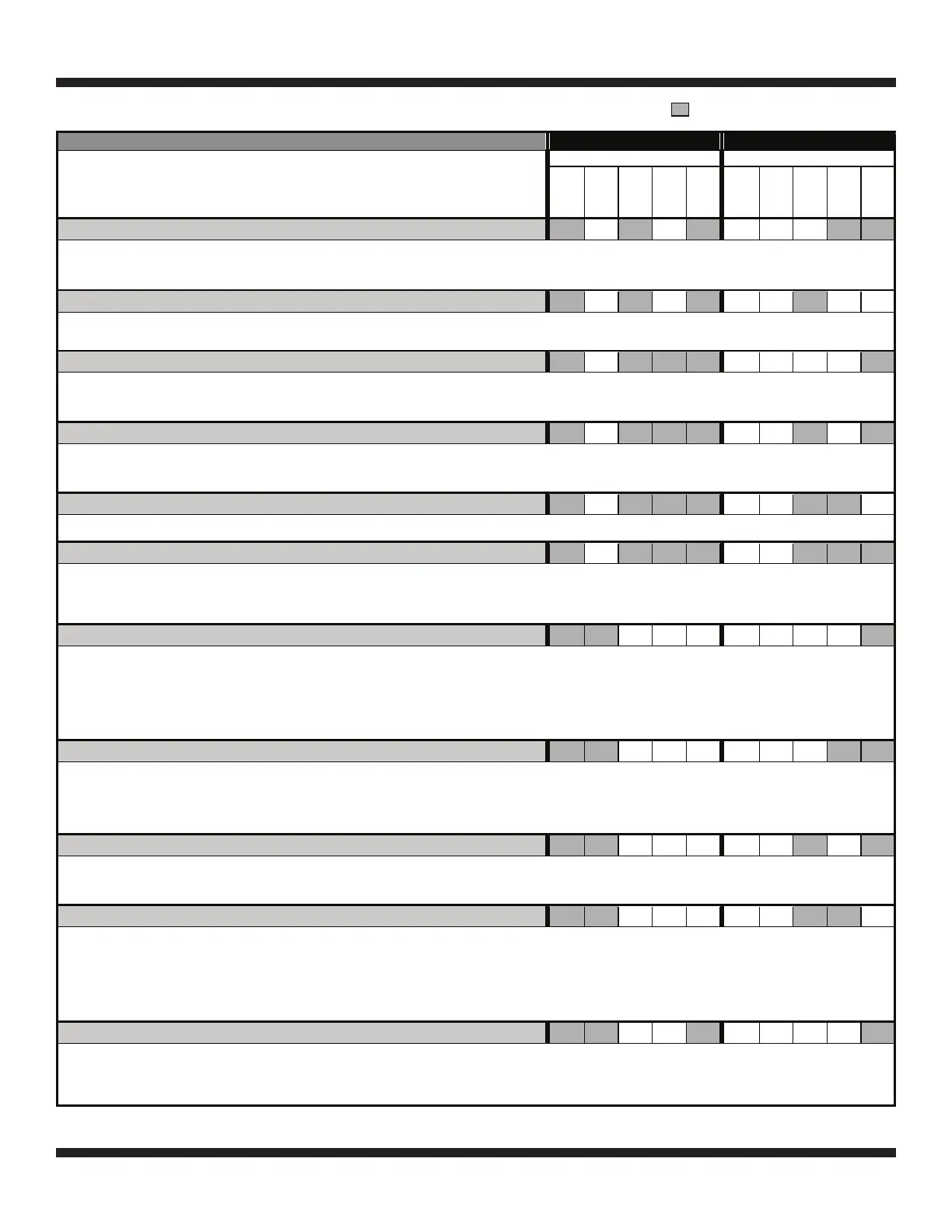

NOTE: If the In Use LED is ON, the fault code is represented; if OFF, the error code is represented.

FAULT/ERROR CODES (cont.) — See page 3 to access Fault Code Display Mode. = ON

F8E6 – NO FILL

Fault is displayed when the water level does not change for a period of time OR water is present but main control does not detect the water level changing.

Opening and closing the lid will clear the error being displayed.

• Is water supply connected and turned on?

• Low water pressure; fill times longer than six minutes. Are hose screens plugged?

• Check for proper drain hose installation. Is water siphoning out of the drain hose?

• Drain hose must not be more than 4.5" (114 mm) into the drain pipe.

• Check pressure hose connection from tub to pressure sensor. Is hose pinched, kinked, plugged, or leaking air?

• See TEST #2: Valves, page 13.

FAULT/ERROR CODE – DESCRIPTION

SOAK/

WASH

RINSE

FINAL

SPIN

DONE

IN

USE

SOAK/

WASH

RINSE

FINAL

SPIN

DONE

F5E3 – LID UNLOCK FAULT

F7E1 – BASKET SPEED SENSOR FAULT

F7E5 – SHIFTER FAULT

F8E1 – LONG FILL

F8E3 – OVERFLOW CONDITION

F8E5 – HOT, COLD REVERSED

F9E1 – LONG DRAIN

Status LEDs

ERROR NUMBERFAULT NUMBER

Fault is displayed when main control senses water level that exceeds the washer’s capacity.

• May signify problem with inlet water valves.

• Check pressure hose connection from tub to pressure sensor. Is hose pinched, kinked, plugged, or leaking air?

• Check for an onboard pressure transducer fault.

• See TEST #2: Valves, page 13 and TEST #6: Water Level, page 17.

Fault is displayed when the hot and cold inlet hoses are reversed.

• Make sure inlet hoses are connected correctly.

• If hoses are installed properly, temperature thermistor may be stuck in low resistance range.

• See TEST #2: Valves, page 13 and TEST #5: Temperature Thermistor, page 16.

Fault is displayed when the main control cannot determine speed of basket, or speed changes too quickly.

• Locked rotor—check that basket, impeller, and motor can rotate freely.

• Check harness connections from main control to motor and shifter.

• See TEST #3a: Drive System – Shifter, page 13.

Fault is displayed when the main control cannot determine position of shifter.

• Check harness connections from main control to motor and shifter.

• Observe shifter operation.

• See TEST #3a: Drive System – Shifter, page 13.

Fault is displayed if Lid Lock has not moved into unlocked position or motor cannot be powered.

• Check for lock interference with lock striker.

• Main control cannot determine if lid lock is in an unlocked state.

• See TEST #8: Lid Lock, page 18.

Fault is displayed when the water level does not change for a period of time OR water is present but main control does not detect the water level changing.

Opening and closing the lid will clear the error being displayed.

• Is water supply connected and turned on?

• Low water pressure; fill times longer than six minutes. Are hose screens plugged?

• Check for proper drain hose installation. Is water siphoning out of the drain hose?

• Drain hose must not be more than 4.5" (114 mm) into the drain pipe.

• Check pressure hose connection from tub to pressure sensor. Is hose pinched, kinked, plugged, or leaking air?

• See TEST #2: Valves, page 13.

Status LEDs

Fault is displayed when the water level does not change after the drain pump is on for 10 minutes.

• Is the drain hose or the drain pump clogged? Check tub sump under impeller for obstructions.

• Is the drain hose height greater than 96" (2.4 m)?

• Check pressure hose connection from tub to pressure sensor. Is hose pinched, kinked, plugged, or leaking air?

• Is the pump running? If not, see TEST #7: Drain Pump, page 17.

1

F5E4 – LID NOT OPENED BETWEEN CYCLES

4

Fault is displayed if the following conditions occur:

• User presses START after several consecutive washer cycles without opening lid.

• See TEST #8: Lid Lock, page 18.

4

F7E6 – MOTOR FAULT

2

Indicates an open clockwise or counterclockwise circuit of the motor.

• See TEST #3b: Drive System – Motor, page 14.

F7E7 – MOTOR UNABLE TO REACH TARGET RPM

Fault is displayed when basket speed sensor detects that target RPM was not reached.

• Mechanical friction on drive mechanism or basket (clothing between basket and tub).

2

• Weak motor or run capacitor, or no connection to run capacitor.

• Load off balance. Clothing should be distributed evenly when loading.

• See TEST #3b: Drive System – Motor, page 14.

1

E482

1

48

1

21

421

4421

21

1

1

1

Explanation & Recommended Procedure

(Status LED names may vary between makes and models)

IN

USE

F

E

F E

• Not pumping—pressure transducer closed or shorted in standby, or after washer completes a cycle.

F E

F E

F E

2

Loading...

Loading...