2-6

n

R600A Sealed System

Sealed System Repair

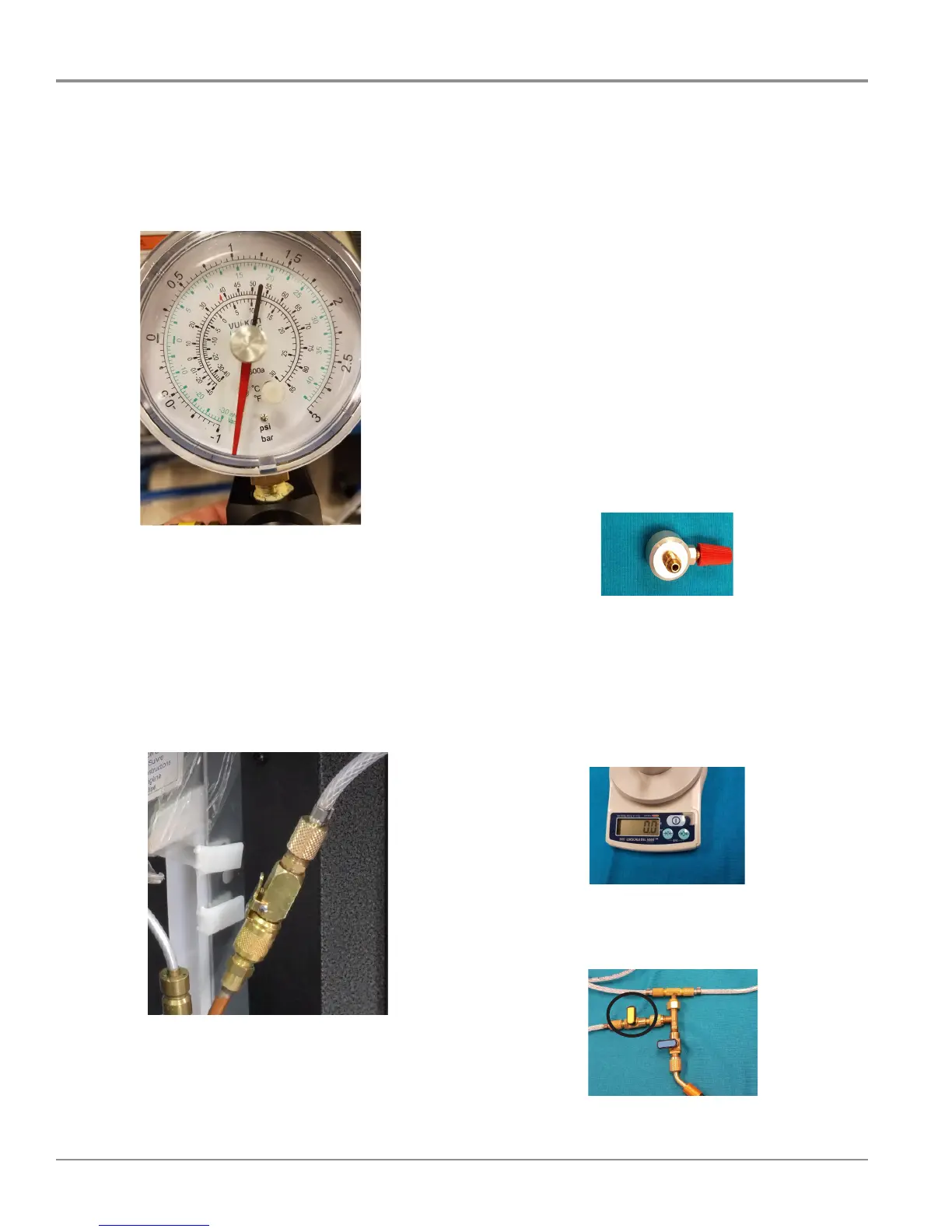

¾ Turn the vacuum pump on and let it warm up for a few

minutes (warm to touch). Once warm open the ball

valve at the hose coming from the vacuum pump to

T-connecon. Open the Low Pressure gauge manifold

valve. Watch needle on the low pressure gauge unl it

reaches it’s lowest vacuum reading posion.

¾ When the Low Pressure gauge needle reaches the lowest

vacuum reading, set the adjustable set pointer to cover

the vacuum needle. Close the ball valve on vacuum

pump hose. The Low Pressure / Vacuum gauge must hold

without dropping for a minimum of 60 seconds. This test

ensures that all connecons of the lling equipment are

ght and leak free.

¾ Connect the quick coupling to the Low and High side

compressor lling tube. (If evacuang both sides) connect

the High Pressure quick coupling to the dryer. Slowly open

the ball valve in line to the vacuum pump.

¾ Evacuate unl the Low Pressure gauge reaches the

previously set posion (about 5 mintes) of the adjustable

shadow needle. Close o the Valve to the Vacuum Pump

and wait at lease 60 seconds.

¾ Watch the shadow needle for any deecon. If you do

not see any movement you can connue and Evacuate

for adddional 10 minutes.

¾ If you do see movement in the needle you may have a

leak in the sealed system that needs to be repaired.

¾ If no pressure change (vacuum needle stays steady

behind shadow needle), the charging process can be

started.

Charging Process

¾ At this point you can remove the High side quick connect

from the lter dryer. Keep the High side valve open and

connected. This is to remove the remaining refrigerant in

the hoses in the last step.

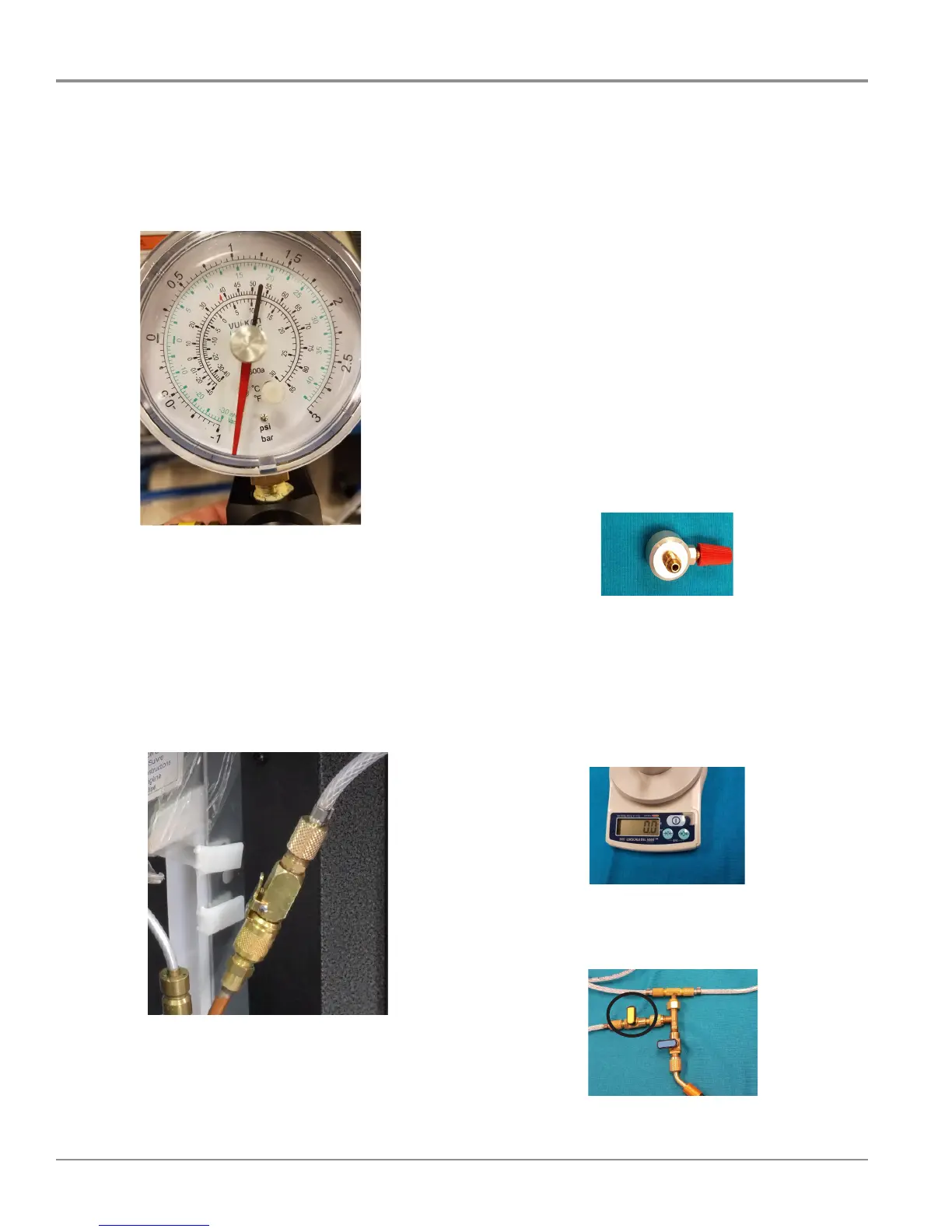

¾ Close the ball valve to the charging staon at the lower

T-ng. Switch on the scale and set to zero.

¾ Open the discharge valve on the refrigerant bole and

allow the gas to ow into the hoses.

Discharge valve on the refrigerant bottle

¾ Note for liquid filling (This is the preferred process)

¾ When filling with liquid refrigerant, the bottle is screwed

into the holder with the closed extraction valve in place

on the bole. The bole is placed upside down on the

scale.

¾ Switch the scale on and reset to zero(Figure S). Make

sure Lower T-connecon ball valve to charging case is

closed.

Figure S

¾ Open the valve that is connected to the R600a and ll

the hoses with refrigerant up to the ball valve of the

charging case T-piece(Figure T).

Figure T

T-connection ball valve to charging case

Loading...

Loading...