23WIKA operating instructions, model CPG1200

EN

14603921.02 06/2023 EN/DE

WARNING!

Damage to the instrument through improper use

The area of the display can easily be damaged.

▶

Avoid any contact with hard and pointed objects, or any excessive

pressures.

6.1 Mounting the instrument

Only mount the CPG1200 if it is in perfect condition with respect to safety.

Prior to commissioning, the CPG1200 must be subjected to a visual inspection.

To avoid possible damage to the CPG1200 or to test equipment, note the following with

mechanical mounting:

Requirements for mounting point:

▶

Sealing faces are clean and undamaged

▶

Maximum pollution degree of the environment (2)

▶

For information on tapped holes, see technical information IN 00.14 at www.wika.com

▶

Permissible ambient and medium temperatures remain within the performance limits.

→ For performance limits, see chapter 11 “Specifications”

6.1.1 Sealing the process connection

When screwing the threads of the CPG1200 to an adapter or a pressure connection, it

is necessary to use an additional sealant between the threads, e.g. PTFE tape.

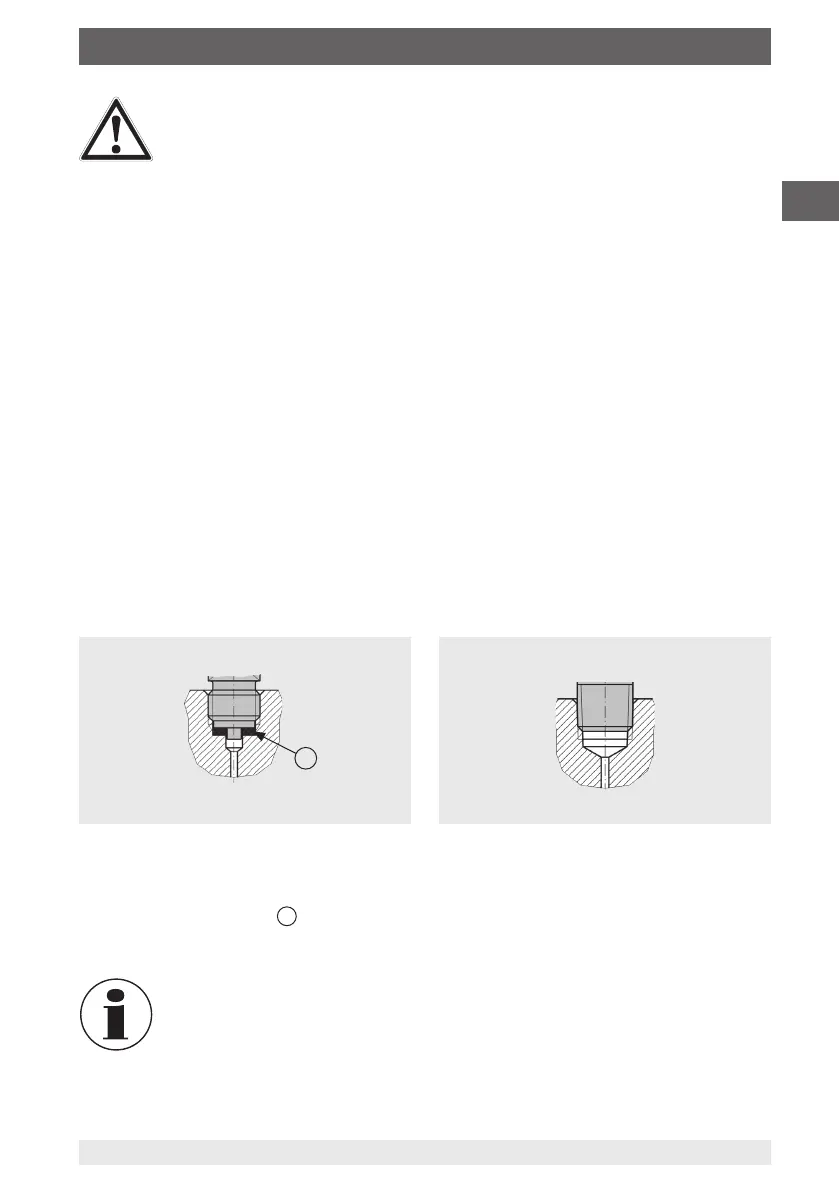

For sealing the process connections with

parallel threads, flat gaskets, lens-type

sealing rings or WIKA profile sealings must

be used at the sealing face

1

.

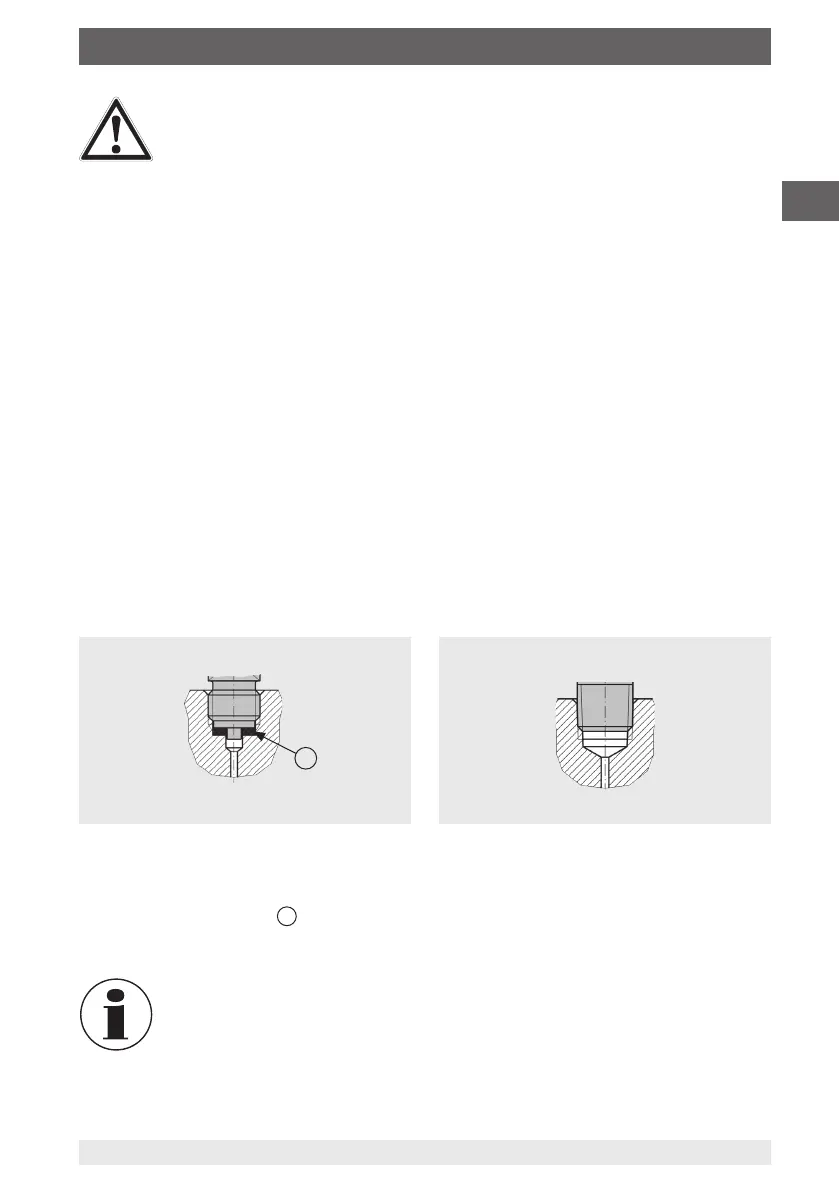

For sealing process connections with tapered

threads, the sealing is made in the threads

using additional sealing material, e.g. PTFE

tape (EN 837-2).

For information on sealings, see WIKA data sheet AC 09.08 or at

www.wika.com.

Parallel threads

per EN 837

1

Tapered threads

NPT, R and PT

6. Commissioning, operation

Loading...

Loading...