0200-40

WII.LYS

AIODEL

"MD"

%-TON

4

x

4

GOVERNhlENT

TI<UCK

Next asseiiible tlie bel1 Iiousing to tlie erigiiie.

The clutcli release bearing No.

O.

Fig.

2

is

pre-

luhricatecl and tlie Iiibricant lasts the life of the

bearing.

If tlie bearing is rough, a new bearing

sliould be installed.

Make sure tliat tlie clutch relcase bearing carrier

return spring No.

7,

Fig.

2

is hooked into place. For

tlie

balance of the assemhly, reverse the operations

that

were used in the disassenibly. referring to in-

structions given under "'l'ransmission." Finally

adjust the clutch release cnhle so tliere

is

%>'

free

pedal travel before relcasc Licaring contacts tlie

fingers.

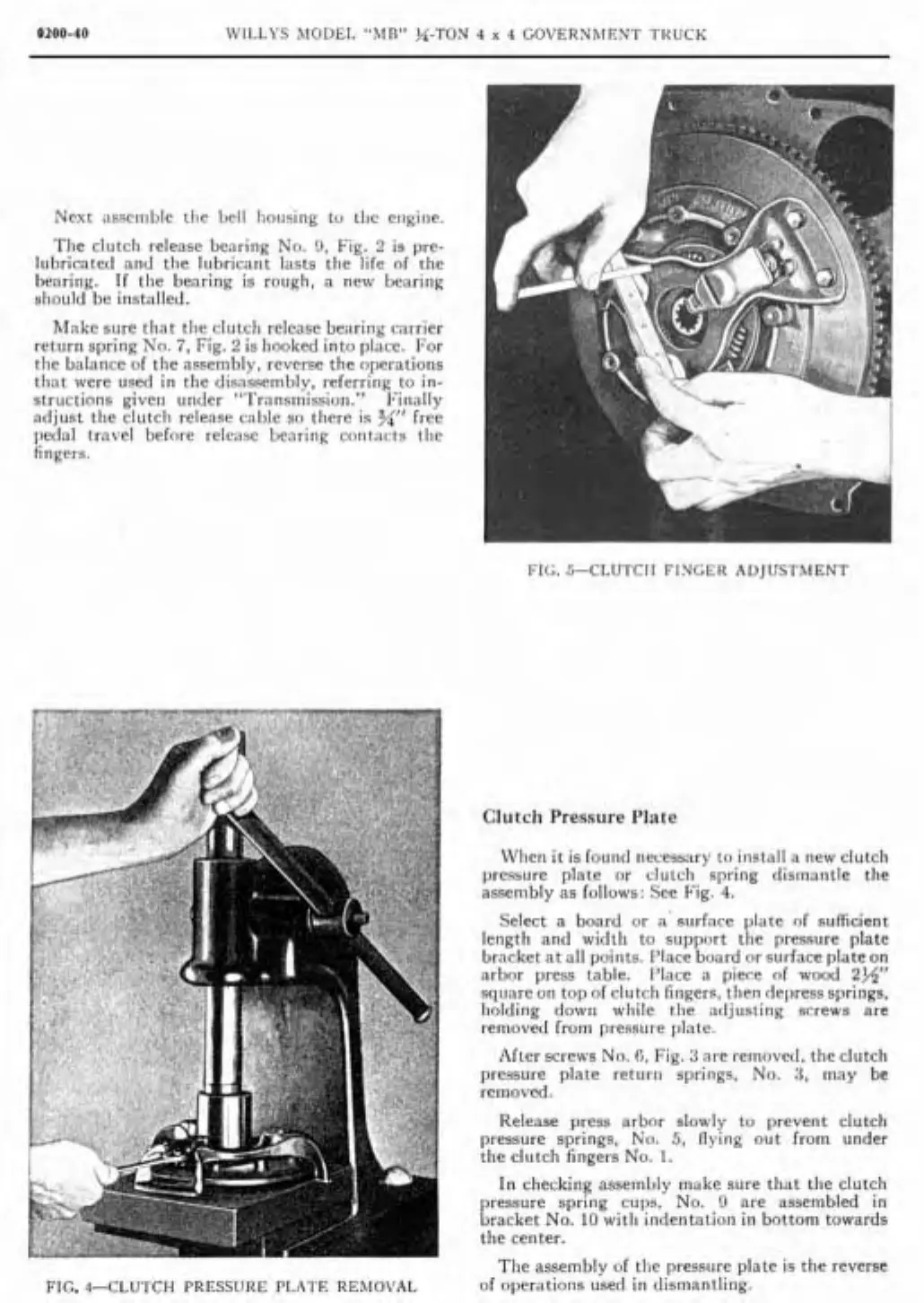

FIG.

4-CLUTCH

PRESSURE

PL,\1'E

REAIOVAL

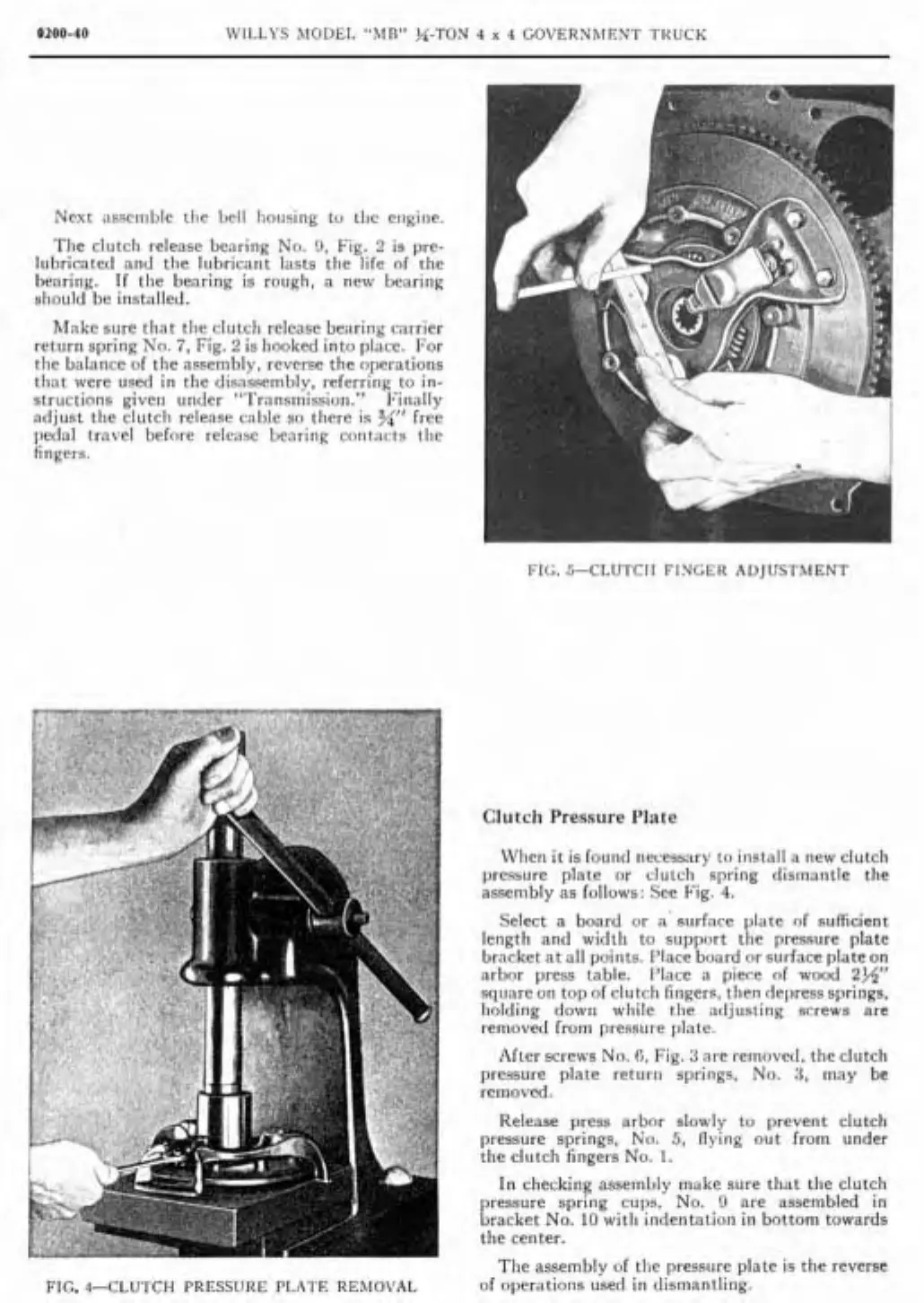

Clutch Pressure Plate

When it

is

fouiid necessary to iiistall a new clutch

pressure plate or clutch spring dismantle the

assenibly as follows: See Fig.

4.

Select

a

board or a' surface plate

of

sufficient

length and wi<ltli to support tlie pressure plate

bracket at

al1

poiiits. Place board or siirface plate on

arbor

press table. I'lace a piece of wood

2W

square on top of clutch fingers. tlien depress springs.

holding down wliile tlie adjustilig screws are

removed from pressiire plate.

After screws No.

R,

Fig.

3

are removecl, the clutch

pressure plate returii spriiigs. No.

R,

may be

rernoved.

Release press arbor slowly to prevent clutch

pressure springs. No.

5,

flying out frorn under

the clutch

fingers No.

1.

In checking assembly make sure that tlie clutch

pressure spring clips, No.

O

are assenibled in

bracket No.

10

witli indentation in bottorn towards

the center.

Tlie

assembly of tlie pressiire plate is the reverse

of operations used in dismantling.

Loading...

Loading...