10. Faults, causes and remedies

Only have faults remedied by qualified personnel!

Observe safety instructions in 9 Maintentance.

If the fault cannot be remedied, please

contact the trade or your nearest

Wilo-After-sales Service or agent.

18 WILO SE 09/2014

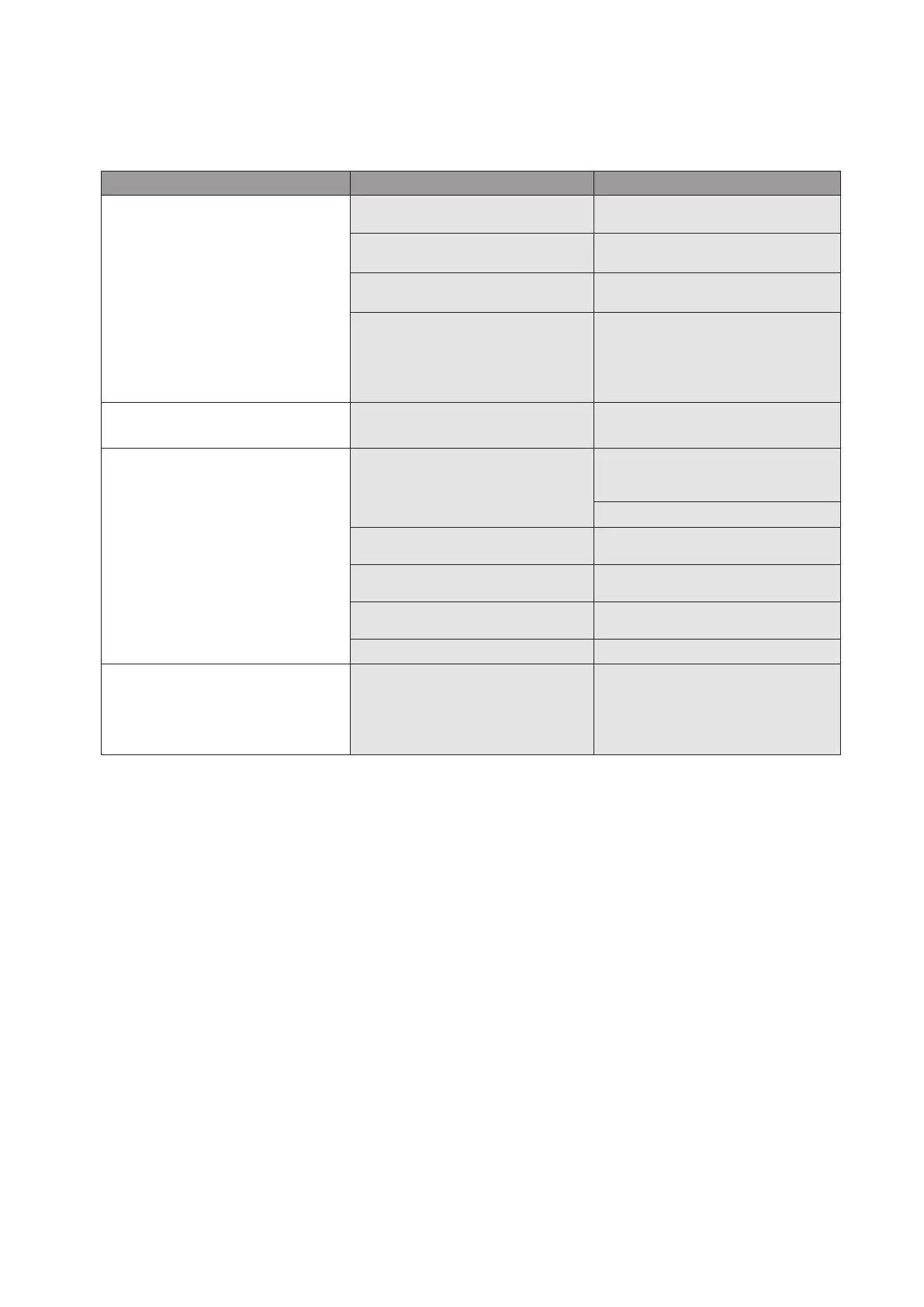

Fault Cause Remedy

The pump does not start or stops

during operation

Current supply interrupted Check fuses, cables and electrical

connections

Motor protection switch has tripped Allow the pump to cool down, it will start

again automatically

Fluid temperature too high Allow to cool down

Pump silted up or blocked Disconnect the pump from the mains and

remove from the shaft.

Remove the suction strainer and rinse

the suction strainer / impeller under run-

ning water

Pump does not switch on/off Float switch blocked or cannot move

freely

Check float switch and ensure mobility

Pump does not pump Air in the installation cannot escape Place the pump at an angle in water

briefly until the air escapes.

Vent the installation / drain if necessary

Check the switch-off level

Water level below the intake port If possible, submerge the pump deeper

(observe the switch-off level)

Pressure pipe / hose diameter too small

(losses too high)

Bigger dimensioning of the pressure pipe

/ hose diameters

Non-return valve sticking in the pres-

sure port

check function

Hose kinked / check valve closed Clear kink in hose / open check valve

Flow rate drops during operation Suction strainer blocked / impeller

blocked

Disconnect the pump from the mains and

remove from the shaft.

Remove the suction strainer and rinse

the suction strainer / impeller under run-

ning water

English

Loading...

Loading...