Do you have a question about the Wilo EMU FA and is the answer not in the manual?

Explains the purpose and usage guidelines of the manual.

States Wilo's copyright and prohibits unauthorized use of content.

Informs about Wilo's right to make technical changes without notice.

Lists conditions under which Wilo is not liable for warranty claims.

Explains safety symbols, signal words, and their meanings.

Details required qualifications and training for personnel performing tasks.

Specifies requirements and regulations for electrical work on the product.

Lists essential monitoring devices like circuit breakers and motor protection switches.

Advises on safety precautions and cleaning when handling hazardous fluids.

Provides notes on permanent magnet motors, including magnetic fields and generator operation.

Outlines safety precautions and procedures for transporting the product.

Details safety measures, PPE, and procedures for installation and dismantling.

Covers safety during operation, including PPE, work area restrictions, and fault reporting.

Specifies PPE and general rules for performing maintenance tasks safely.

Describes the operating fluid and its handling during maintenance.

Outlines the operator's duties regarding training, PPE, and system safety.

Defines the approved applications and types of fluids the pump can handle.

Warns against dangerous improper uses, especially with explosive or hazardous fluids.

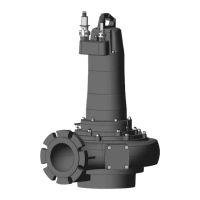

Describes the pump's construction, including hydraulics and motor types.

Explains the function and usage of the Digital Data Interface module.

Overviews the internal and external monitoring devices available for the motor.

Details different operating modes like continuous and non-immersed operation.

Covers requirements and considerations for operating the motor with a frequency converter.

Provides guidelines for operating the pump in potentially explosive environments.

Explains the abbreviations and data found on the product's rating plate.

Details the coding system for identifying different hydraulic and motor types.

Lists the components included in the standard and configured pump deliveries.

Lists optional accessories that can be attached to the pump.

Instructions for checking the delivered goods for defects and reporting issues.

Safety precautions and guidelines for transporting the pump.

Recommendations for storing the pump properly to maintain its condition.

Specifies the required qualifications for personnel performing installation and electrical work.

Describes the permitted and prohibited installation methods for the pump.

Outlines operator duties related to installation, safety regulations, and foundations.

Details procedures and safety warnings for installing the pump in various configurations.

Covers the crucial steps and safety precautions for connecting the pump electrically.

Specifies qualifications for personnel involved in commissioning.

Outlines operator duties for ensuring proper commissioning and system functionality.

Explains how to check and correct the motor's direction of rotation.

Provides critical safety instructions for operating the pump in explosive environments.

Lists essential checks to perform before activating the pump.

Describes the procedure for switching the pump on and off and handling startup issues.

Covers safety aspects and operational checks during pump running.

Specifies qualifications for personnel performing shutdown and dismantling.

Outlines operator duties for safe shutdown and dismantling procedures.

Explains how to shut down the pump while keeping it installed.

Details safety precautions and steps for removing the pump.

Specifies qualifications for personnel performing maintenance and repair.

Outlines operator duties for maintenance, including PPE and parts.

Details the types and filling quantities of operating fluids used.

Provides recommended maintenance intervals for normal and harsh conditions.

Describes various visual inspections and function tests for maintenance.

Outlines general principles and specific instructions for performing repairs.

Instructions for collecting and disposing of oils and lubricants.

Guidelines for disposing of used protective clothing.

Information on recycling electrical and electronic products and environmental protection.

How to identify pumps with explosion protection certification on the rating plate.

Describes the motor's design version and corresponding protection classes.

Details the intended use of pumps in potentially explosive atmospheres and warnings.

Critical safety and connection guidelines for electrical work in potentially explosive areas.

Steps and safety checks for commissioning pumps in explosive atmospheres.

Regulations and restrictions for performing maintenance and repair on Ex-rated pumps.

Lists tightening torques for various screw sizes.

Explains how to operate the motor with a frequency converter and related considerations.